Advanced Acetylcholinesterase Immobilization Techniques for Next-Generation Electrochemical Biosensors

This article provides a comprehensive analysis of contemporary strategies for immobilizing acetylcholinesterase (AChE) onto electrode surfaces, a critical technology for developing sensitive and stable biosensors.

Advanced Acetylcholinesterase Immobilization Techniques for Next-Generation Electrochemical Biosensors

Abstract

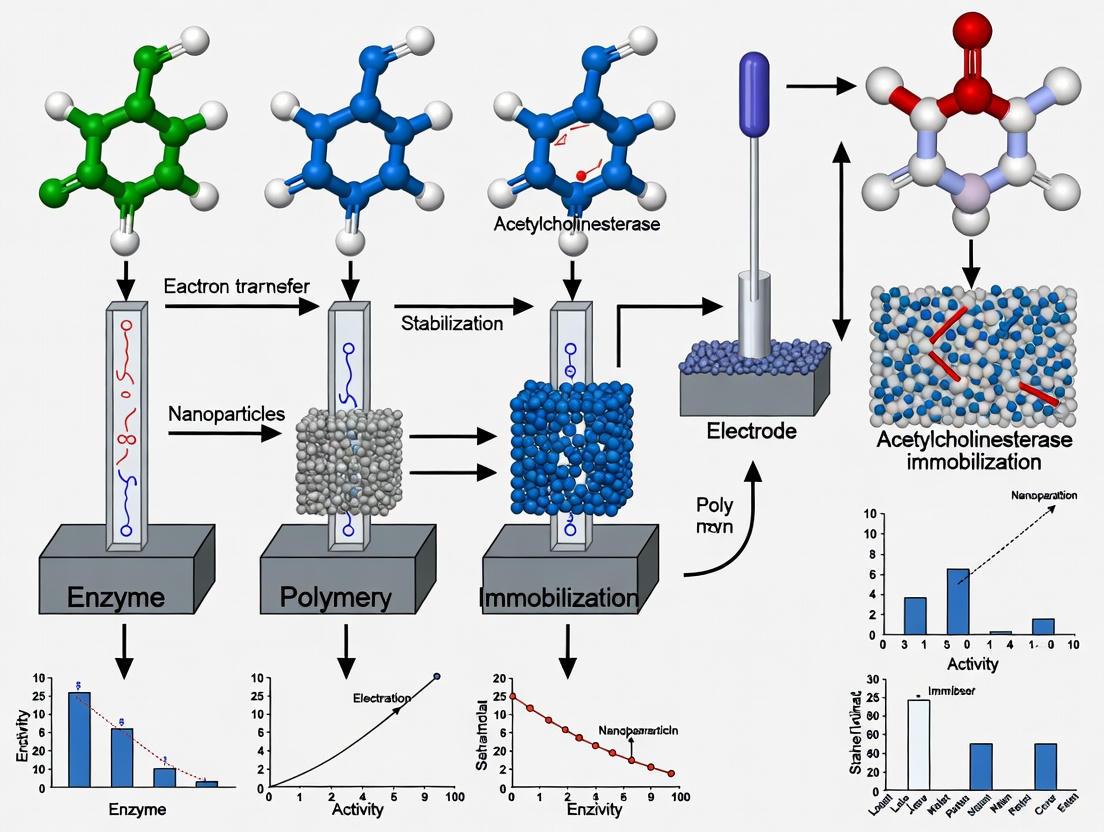

This article provides a comprehensive analysis of contemporary strategies for immobilizing acetylcholinesterase (AChE) onto electrode surfaces, a critical technology for developing sensitive and stable biosensors. Tailored for researchers, scientists, and drug development professionals, the content explores foundational principles, diverse methodological approaches from physical adsorption to covalent bonding on nanostructured platforms, and essential optimization techniques to enhance biosensor performance. It further delivers a critical evaluation of validation protocols and comparative assessments of different immobilization techniques, highlighting their applications in pesticide detection, clinical diagnostics, and therapeutic agent screening. The synthesis of this information aims to serve as a definitive guide for the rational design and implementation of AChE-based biosensing platforms in both research and industrial settings.

Acetylcholinesterase Fundamentals and Immobilization Rationale for Biosensor Design

The Critical Role of AChE in Neurotransmission and as a Biorecognition Element

Biological Function of Acetylcholinesterase in Neurotransmission

Acetylcholinesterase (AChE; EC 3.1.1.7) is a crucial serine hydrolase enzyme concentrated at neuromuscular junctions and cholinergic brain synapses, where it serves a vital function in terminating nerve impulses by catalyzing the hydrolysis of the neurotransmitter acetylcholine (ACh) [1] [2]. This rapid hydrolysis, which occurs in microseconds, ensures the precise control of synaptic transmission necessary for proper muscle function and cognitive processes [1].

The enzyme's catalytic mechanism involves an active site containing a catalytic triad of serine, histidine, and glutamate residues [2]. The hydrolysis reaction proceeds through a two-step process: First, ACh binds to the enzyme's active site, where the serine residue undergoes nucleophilic attack on the carbonyl carbon of acetylcholine. This results in the cleavage of the ester bond, releasing choline and forming an acetylated enzyme intermediate. Second, the acetyl group is rapidly hydrolyzed, releasing acetic acid and regenerating the free enzyme [1]. This process maintains the delicate balance of neurotransmitter levels essential for normal nervous system function.

Figure 1: AChE in Neurotransmission. AChE terminates neuronal signaling by hydrolyzing acetylcholine (ACh) in the synaptic cleft, allowing for signal precision and choline recycling.

When AChE activity is inhibited by toxic compounds such as organophosphorus pesticides or nerve agents, acetylcholine accumulates in the synaptic cleft, leading to continuous stimulation of muscles and glands [1] [3]. This cholinergic hyperexcitability manifests as a range of symptoms from headache and confusion to respiratory failure and death, underscoring the critical importance of AChE in maintaining neurological homeostasis [1].

AChE as a Biorecognition Element in Analytical Applications

The exceptional specificity of AChE for its substrate, coupled with its sensitivity to inhibition by various toxic compounds, makes it an excellent biorecognition element in biosensor technology [4] [5]. AChE-based biosensors have emerged as ultra-sensitive and rapid analytical tools for toxicity monitoring in environmental, food, and clinical applications [5].

The fundamental principle underlying these biosensors involves measuring the decrease in AChE activity upon exposure to inhibitors, which is directly proportional to the concentration of the toxicant present [1]. In a typical configuration, the biosensor consists of AChE immobilized on a transducer surface. When the substrate acetylthiocholine is introduced, the enzymatic reaction produces electroactive thiocholine, which generates a measurable signal. In the presence of inhibitors, this signal decreases due to the reduced enzymatic activity [1] [6].

Detection capabilities of AChE-based biosensors span multiple classes of toxic compounds:

Table 1: Analytical Performance of AChE-Based Biosensors for Various Analytes

| Analyte Class | Specific Examples | Detection Limit | Linear Range | Application Context |

|---|---|---|---|---|

| Organophosphorus Insecticides | Paraoxon, Dichlorvos, Chlorpyrifos ethyl oxon | 10⁻⁸ to 10⁻⁹ M [7] | Not specified | Environmental monitoring, food safety [7] |

| Carbamate Pesticides | Carbofuran, Aldicarb | Not specified | Not specified | Agricultural monitoring [5] |

| Chemical Warfare Agents | Sarin, Soman, Tabun, VX | 7.41×10⁻¹² M (Sarin) to 6.17×10⁻¹¹ M (Tabun) [3] | 10⁻¹¹ to 10⁻⁴ M [3] | Defense, security, emergency response [3] |

| Heavy Metals | Arsenic(III), Mercury(II) | 1.1×10⁻⁸ M (As³⁺) [6] | 10⁻⁸ to 10⁻⁷ M [6] | Environmental water monitoring [6] |

| Natural Toxins | Aflatoxins | Not specified | Not specified | Food quality control [4] |

The versatility of AChE biosensors extends to multiple transduction methods, including amperometric, potentiometric, colorimetric, and fluorometric systems, each offering distinct advantages for specific applications [2] [5]. Recent advances have incorporated nanomaterials and recombinant enzyme engineering to enhance sensitivity, selectivity, and stability [1] [4].

Experimental Protocols for AChE Immobilization and Biosensor Application

AChE Immobilization on Screen-Printed Electrodes: Comparative Methods

The immobilization of AChE onto transducer surfaces represents a critical step in biosensor fabrication, significantly influencing performance parameters including sensitivity, stability, response time, and reproducibility [1] [7]. Below are three validated protocols for AChE immobilization on screen-printed electrodes (SPEs):

Protocol 1: Entrapment in a Photopolymerisable Polymer (PVA-SbQ)

- Material Preparation: Prepare a solution containing AChE (0.8-1.2 mIU) in 0.1 M phosphate buffer (pH 7.4). Mix thoroughly with poly(vinyl alcohol) bearing styrylpyridinium groups (PVA-SbQ) polymer precursor.

- Electrode Modification: Deposit 2-5 μL of the enzyme-polymer mixture onto the working electrode surface of SPEs.

- Photopolymerization: Expose the modified electrode to UV light (λ = 360 nm) for 5 minutes to achieve cross-linking and polymer formation.

- Rinsing and Storage: Rinse the biosensor with phosphate buffer to remove unentrapped enzyme. Store at 4°C in dry conditions when not in use [7].

Protocol 2: Bioencapsulation in Sol-Gel Composite

- Sol-Gel Preparation: Mix 200 μL of methyltrimethoxysilane (MTMOS) with 60 μL of HCl (1 mM) and sonicate for 30 seconds until a clear solution forms.

- Enzyme-Ink Formulation: Combine the sol-gel solution with AChE (0.8-1.2 mIU), graphite powder, hydroxyethyl-cellulose (1% w/v), and polyethylene glycol 600 (1% w/v) to form a homogeneous ink.

- Electrode Printing: Apply the enzyme-containing ink to the working electrode area of SPEs using screen-printing technology.

- Curing: Allow the biosensor to cure at room temperature for 24 hours to complete the gelation process [7].

Protocol 3: Covalent Immobilization via Metal-Chelate Affinity

- Surface Functionalization: Modify the electrode surface with a chelating agent (e.g., iminodiacetic acid) and charge with Ni²⁺ ions.

- Enzyme Engineering: Utilize recombinant AChE-(His)₆ from Drosophila melanogaster containing a hexahistidine tag.

- Enzyme Attachment: Incubate the functionalized electrode with the modified AChE solution for 60 minutes at 25°C to allow specific metal-chelate coordination.

- Washing: Rinse thoroughly with phosphate buffer to remove non-specifically bound enzyme [7].

Table 2: Performance Comparison of AChE Immobilization Methods

| Immobilization Method | Apparent Km (mM) | Storage Stability | Relative Activity Retention | Advantages | Limitations |

|---|---|---|---|---|---|

| Photopolymerisable Polymer (PVA-SbQ) | 0.67 [7] | >6 months [7] | High (>80%) [7] | Rapid process, good enzyme activity retention | Potential enzyme leakage, diffusion barriers |

| Sol-Gel Encapsulation | 0.32 [7] | >6 months [7] | Moderate to high [7] | Mild preparation conditions, tunable porosity | Brittleness, possible mass transfer limitations |

| Metal-Chelate Affinity | 0.45 [7] | Not specified | High [7] | Oriented immobilization, minimized enzyme denaturation | Requires engineered enzyme, complex preparation |

| Gelatin-Glutaraldehyde Cross-linking | Not specified | >1 month at 4°C [3] | High [3] | Simple protocol, low cost | Potential over-crosslinking reducing activity |

Protocol for Detection of Organophosphorus Compounds Using AChE Biosensors

Principle: Organophosphorus (OP) compounds irreversibly inhibit AChE, reducing the enzymatic conversion of acetylthiocholine to thiocholine, which is electrochemically detectable [1] [7].

Materials Required:

- AChE biosensor (prepared according to above protocols)

- Phosphate buffered saline (PBS, 0.1 M, pH 7.4)

- Acetylthiocholine chloride substrate solution (10 mM in PBS)

- Standard solutions of OP compounds (paraoxon, dichlorvos, etc.)

- Electrochemical workstation with chronoamperometric capability

Procedure:

- Biosensor Conditioning: Hydrate the AChE biosensor in PBS for 5 minutes before use.

- Inhibition Phase: Incubate the biosensor in sample solution (or standard OP solutions) for 20 minutes at 25°C.

- Measurement Phase: Transfer the biosensor to an electrochemical cell containing 800 μL PBS. Add 100 μL of acetylthiocholine solution (final concentration 1 mM).

- Signal Detection: Apply a potential of +640 mV (vs. Ag/AgCl) and measure the oxidation current of thiocholine for 60 seconds [7] [3].

- Data Analysis: Calculate percentage inhibition using the formula: % Inhibition = [(I₀ - I)/I₀] × 100, where I₀ is the current from uninhibited biosensor and I is the current from sample-exposed biosensor.

Validation Parameters:

- Limit of detection: 10⁻⁸ to 10⁻⁹ M for paraoxon [7]

- Linear range: 10⁻¹⁰ to 10⁻⁶ M [7]

- Reproducibility: RSD <4% [6]

- Total analysis time: <25 minutes

Figure 2: AChE Inhibition Assay Workflow. The protocol for detecting cholinesterase inhibitors based on enzyme activity measurement following exposure to sample.

The Researcher's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for AChE Biosensor Development

| Reagent/Material | Function/Application | Example Specifications | Technical Notes |

|---|---|---|---|

| Acetylcholinesterase (AChE) | Biorecognition element | Electric eel AChE, 16.7 μkat/mg [3]; Recombinant AChE from D. melanogaster [7] | Source affects sensitivity to inhibitors [5] |

| Acetylthiocholine chloride | Enzyme substrate | 10 mM in buffer [3] | Electroactive product (thiocholine) enables amperometric detection |

| Screen-printed electrodes (SPEs) | Transducer platform | Pt working electrode (diameter 1 mm), Pt auxiliary, Ag/AgCl reference [3] | Enable mass production, disposable use [7] [6] |

| Glutaraldehyde | Cross-linking agent | 1% (w/v) in immobilization matrix [3] | Stabilizes immobilized enzyme; concentration critical to prevent over-crosslinking |

| Methyltrimethoxysilane (MTMOS) | Sol-gel precursor | Mixed with HCl (1 mM) for hydrolysis [7] | Forms porous matrix for enzyme encapsulation |

| Poly(vinyl alcohol) bearing styrylpyridinium groups (PVA-SbQ) | Photopolymerizable matrix | UV light (λ = 360 nm) for 5 min cross-linking [7] | Enables rapid enzyme entrapment under mild conditions |

| Phosphate buffered saline (PBS) | Measurement buffer | 0.1 M, pH 7.4 [3] | Optimal for AChE activity and stability |

| 5,5'-dithiobis(2-nitrobenzoic acid) (DTNB) | Colorimetric reagent | Ellman's method for activity assessment [7] | Produces yellow anion for spectrophotometric detection |

Core Principles of Electrochemical AChE Biosensors and Inhibition-Based Detection

Electrochemical biosensors based on acetylcholinesterase (AChE) inhibition represent a powerful analytical platform for detecting various toxic compounds, including organophosphorus pesticides and chemical warfare agents. These biosensors function on the principle that specific inhibitors permanently block AChE's catalytic activity, enabling highly sensitive quantification of these analytes. The core mechanism involves immobilizing AChE on an electrode surface, where it hydrolyzes the substrate acetylthiocholine (ATCh) to produce thiocholine, an electroactive product that generates a measurable current. When AChE is inhibited, the production of thiocholine decreases, resulting in a diminished electrochemical signal proportional to the inhibitor concentration [8] [6].

The performance of these biosensors critically depends on two fundamental aspects: the method employed to stably attach AChE to the electrode surface while preserving its biological activity, and the choice of electrode materials that enhance electron transfer and signal amplification. Recent advancements have incorporated innovative nanomaterials and immobilization strategies to achieve unprecedented sensitivity and stability, pushing detection limits to sub-parts-per-billion levels for certain analytes [8] [9] [10]. This document provides a comprehensive technical resource for researchers developing these biosensing platforms, featuring detailed protocols, performance comparisons, and essential methodological considerations framed within contemporary research on AChE immobilization techniques.

Core Principles and Signaling Mechanisms

The operational principle of AChE biosensors relies on the enzyme-catalyzed hydrolysis of acetylthiocholine chloride (ATCl) and the subsequent electrochemical detection of the reaction product. In the uninhibited state, AChE catalyzes the hydrolysis of ATCl to produce thiocholine (TCh) and acetic acid. The generated TCh is then electrochemically oxidized at the electrode surface, typically at a defined applied potential. This oxidation reaction produces a measurable amperometric current that serves as the baseline signal [8] [6].

When organophosphorus compounds (OPs) or other AChE inhibitors are present, they phosphorylate or carbamylate the serine residue within the enzyme's active site, leading to irreversible inhibition. This modification drastically reduces the enzyme's catalytic activity, resulting in decreased TCh production and a consequent reduction in the oxidation current. The percentage of enzyme inhibition is quantitatively related to the inhibitor concentration and can be calculated using the formula: % Inhibition = [(I₀ - I)/I₀] × 100, where I₀ is the steady-state current before inhibition and I is the current after inhibition and incubation [6]. This relationship forms the quantitative foundation for analyte detection, with the incubation time being a critical parameter influencing sensitivity.

Table 1: Key Reaction Steps in AChE Inhibition Biosensing

| Step | Process | Description | Output |

|---|---|---|---|

| 1 | Enzyme Reaction | AChE hydrolyzes acetylthiocholine chloride | Thiocholine + Acetic Acid |

| 2 | Electrochemical Detection | Thiocholine oxidation at electrode surface | Measurable current signal |

| 3 | Inhibition Mechanism | Organophosphorus compounds phosphorylate AChE | Irreversible enzyme inactivation |

| 4 | Signal Measurement | Reduced thiocholine production decreases current | Quantitative inhibition reading |

Diagram 1: AChE Biosensor Inhibition Mechanism

Performance Comparison of AChE Biosensor Platforms

Recent research has demonstrated remarkable advancements in AChE biosensor technology through the implementation of novel nanomaterials and immobilization strategies. The integration of graphene oxide (GO), polyaniline (PANI), silver nanoparticles (AgNPs), and MXene quantum dots has yielded systems with exceptional sensitivity and wide linear dynamic ranges. These nanomaterials serve dual functions: providing high-surface-area scaffolds for efficient enzyme immobilization and enhancing electron transfer kinetics for signal amplification [8] [10].

The detection limits achieved by contemporary biosensor configurations surpass those of conventional analytical methods for certain applications, with some platforms capable of detecting organophosphorus compounds at concentrations as low as 1.07 × 10⁻⁶ ppb for omethoate and 1 × 10⁻¹⁷ M for chlorpyrifos [8] [10]. The following table provides a comprehensive comparison of recently reported AChE biosensor platforms, highlighting their analytical performance characteristics for various target analytes.

Table 2: Performance Comparison of Advanced AChE Biosensor Platforms

| Sensor Architecture | Target Analyte | Linear Range | Detection Limit | Optimal Conditions | Reference |

|---|---|---|---|---|---|

| AChE/AgNPs/GO/PANI/SPCE | Dimethyl methylphosphonate (DMMP) | Not specified | 6.43 × 10⁻⁵ ppb | 0.1 M PBS, pH 7.5, 12-min incubation | [8] |

| AChE/AgNPs/GO/PANI/SPCE | Omethoate | Not specified | 1.07 × 10⁻⁶ ppb | 0.1 M PBS, pH 7.5, 12-min incubation | [8] |

| AChE/Ti₃C₂Tₓ MQDs/SPCE | Chlorpyrifos | 10⁻¹⁴ – 10⁻⁸ M | 1 × 10⁻¹⁷ M | Differential Pulse Voltammetry | [10] |

| AChE/SPCE (covalent) | Arsenic(III) | 1 × 10⁻⁸ to 1 × 10⁻⁷ M | 1.1 × 10⁻⁸ M | Britton-Robinson buffer pH 7, +0.6 V applied potential | [6] |

| Right-side-out RBCM-coated biosensor | Huperzine A | Not specified | 0.41 pmol/L | Immunoaffinity immobilization | [9] |

Beyond the analytical performance metrics, the storage stability and reproducibility of these biosensors represent critical parameters for practical implementation. Systems employing enzyme encapsulation in polymer films or sol-gel composites have demonstrated remarkable stability, maintaining functionality for over six months under proper storage conditions [7]. The reproducibility of fabrication processes is equally important, with reported relative standard deviation (RSD) values as low as 2.54% for multiple sensor batches, ensuring consistent performance across different production runs [8].

Detailed Experimental Protocols

Protocol 1: Detection of Organophosphorus Compounds Using Nanomaterial-Modified SPCE

Principle: This protocol describes the fabrication of a high-sensitivity AChE biosensor using graphene oxide (GO), polyaniline (PANI), and silver nanoparticles (AgNPs) co-modified screen-printed carbon electrodes (SPCE) for detecting organophosphorus compounds (OPs) based on enzyme inhibition [8].

Materials Required:

- Screen-printed carbon electrodes (SPCEs)

- Acetylcholinesterase (AChE) from Electrophorus electricus

- Graphene oxide (GO) suspension

- Aniline monomer for PANI synthesis

- Silver nitrate (AgNO₃) for AgNPs synthesis

- Dimethyl methylphosphonate (DMMP) and omethoate as standard OPs

- Acetylthiocholine chloride (ATCl) as enzyme substrate

- Phosphate buffer saline (PBS, 0.1 M, pH 7.5)

- Glutaraldehyde (25%) for cross-linking

Procedure:

- Electrode Modification:

- Synthesize PANI via chemical oxidation of aniline in acidic medium

- Prepare GO suspension through modified Hummers' method

- Electrodeposit AgNPs on SPCE at constant potential

- Apply GO/PANI composite onto AgNPs/SPCE using freeze-drying technique

- Characterize modified electrode using cyclic voltammetry (CV) in potassium ferrocyanide solution

Enzyme Immobilization:

- Prepare AChE solution (concentration optimized based on activity)

- Apply 8 μL AChE solution onto GO/PANI/AgNPs/SPCE surface

- Cross-link with 0.25% glutaraldehyde vapor for 15 minutes

- Rinse with PBS to remove unimmobilized enzyme

- Store at 4°C when not in use

Inhibition and Detection:

- Record baseline current in PBS containing ATCl (0.1-10 mM) using CV

- Incubate inhibited biosensor with OP sample for 12 minutes in PBS (pH 7.5)

- Measure current response after incubation

- Calculate inhibition percentage: % Inhibition = [(I₀ - I)/I₀] × 100

- Generate calibration curve by plotting % inhibition vs. OP concentration

Validation Parameters:

- Linear range: Verify across 3-5 orders of magnitude

- Detection limit: Calculate based on 3×standard deviation of blank/slope

- Reproducibility: Determine using RSD of 5 different sensors

- Selectivity: Test against potential interferents (heavy metals, other pesticides)

Protocol 2: MXene Quantum Dot-Based Ultrasensitive Biosensor for Pesticide Detection

Principle: This protocol utilizes Ti₃C₂Tₓ MXene quantum dots (MQDs) to create an ultrasensitive biosensing platform for detecting organophosphorus pesticides through cholinesterase inhibition, achieving exceptional detection limits via enhanced electron transfer and enzyme stabilization [10].

Materials Required:

- Ti₃AlC₂ MAX phase for MQD synthesis

- Hydrofluoric acid (HF) or lithium fluoride (LiF)/HCl etching solution

- Chitosan (CS) solution (0.5-1% in acetic acid)

- Acetylcholinesterase (500 U/mg)

- Glutaraldehyde (GA, 2.5% in PBS)

- Chlorpyrifos, acephate, glyphosate standards

- Phosphate buffer (0.1 M, pH 7.4)

Procedure:

- MQD Synthesis:

- Etch Ti₃AlC₂ MAX phase in HF or LiF/HCl at 35-45°C for 24-48 hours

- Wash repeatedly with deionized water until supernatant reaches pH ~6

- Perform hydrothermal treatment at 150-200°C for 10-24 hours to form MQDs

- Characterize MQDs using AFM, SEM, and XRD to confirm size (2-5 nm) and structure

Biosensor Fabrication:

- Prepare MQD-chitosan composite (1:3 ratio)

- Deposit 6-8 μL composite solution on clean GCE surface, dry at room temperature

- Apply AChE solution (0.5-2 U) onto MQD-CS/GCE

- Cross-link with 2.5% glutaraldehyde vapor for 30 minutes

- Rinse thoroughly with PBS to remove excess cross-linker

Electrochemical Measurement:

- Employ differential pulse voltammetry (DPV) from 0 to 0.8 V

- Use acetylthiocholine iodide (ACTI) as substrate at optimal concentration (2-5 mM)

- Record DPV response in blank solution (I₀) and after incubation with pesticide (I)

- Utilize standard addition method for real sample analysis

- Validate with in vitro cholinergic activity assays in biological samples

Critical Notes:

- MQD concentration significantly impacts sensitivity—optimize between 1-5 mg/mL

- Cross-linking time affects enzyme activity—test between 15-60 minutes

- Inhibition time directly correlates with sensitivity—standardize at 10-15 minutes

Diagram 2: SPCE Biosensor Fabrication Workflow

The Scientist's Toolkit: Essential Research Reagents and Materials

The development of high-performance AChE biosensors requires careful selection of materials and reagents that collectively determine the analytical characteristics of the final biosensing platform. The table below comprehensively lists essential research reagents, their specific functions, and considerations for selection and optimization.

Table 3: Essential Research Reagents for AChE Biosensor Development

| Reagent/Material | Function/Purpose | Key Considerations |

|---|---|---|

| Acetylcholinesterase | Biological recognition element | Source (electric eel, human recombinant), specific activity (>500 U/mg), stability |

| Screen-printed Carbon Electrodes | Disposable transducer platform | Low cost, mass production capability, customizable design |

| Graphene Oxide (GO) | Nanomaterial for signal amplification | High conductivity, large surface area, enhances electron transfer |

| Polyaniline (PANI) | Conducting polymer matrix | Improves electron transfer rate, stabilizes enzyme immobilization |

| Silver Nanoparticles | Signal enhancement | Biocompatibility, high conductivity, increases coupling probability with AChE |

| MXene Quantum Dots | Novel nanomaterial for ultrasensitive detection | Quantum confinement effects, superior conductivity, high surface-to-volume ratio |

| Acetylthiocholine chloride | Enzyme substrate | Electrochemical conversion to thiocholine, generates measurable signal |

| Glutaraldehyde | Cross-linking agent | Forms stable covalent bonds between enzyme and matrix, concentration critical |

| Chitosan | Biopolymer matrix | Excellent film-forming ability, biocompatibility, non-toxic |

| Phosphate Buffer Saline | Electrochemical measurement medium | Optimal pH (7.0-7.5) for AChE activity, ionic strength affects signal |

Advanced Immobilization Techniques and Methodological Considerations

Comparative Analysis of Immobilization Methods

The strategic immobilization of AChE onto electrode surfaces represents a critical determinant of biosensor performance, influencing enzyme stability, activity retention, and overall sensor longevity. Research has systematically compared multiple immobilization approaches, revealing distinct advantages and limitations for each methodology [7].

Sol-Gel Encapsulation: This technique involves entrapping AChE within a porous silica matrix formed through the hydrolysis and condensation of alkoxide precursors. The sol-gel method provides exceptional storage stability exceeding six months, with demonstrated detection capabilities for paraoxon, dichlorvos, and chlorpyrifos ethyl oxon in the 10⁻⁸ to 10⁻⁹ M range following a 20-minute incubation period. The encapsulation process protects the enzyme from denaturation while allowing substrate and product diffusion, though potential limitations include reduced enzyme activity due to conformational constraints and slower response times resulting from additional diffusion barriers [7].

Metal-Chelate Affinity Immobilization: This approach utilizes engineered AChE containing polyhistidine tags (AChE-(His)₆) that specifically interact with metal ions (typically Ni²⁺ or Cu²⁺) coordinated on the electrode surface. The method enables oriented immobilization, potentially preserving more active sites accessible to substrate. Comparative studies have shown slightly improved Michaelis-Menten constants (Kₘᵃᵖᵖ = 0.45 mM) compared to other methods, indicating potentially better substrate accessibility. However, the requirement for enzyme engineering and possible metal ion leakage represent practical limitations for some applications [7].

Photopolymerizable Entrapment: This technique involves incorporating AChE within a poly(vinyl alcohol) bearing styrylpyridinium groups (PVA-SbQ) matrix that polymerizes upon UV light exposure. This method offers rapid and simple enzyme immobilization with minimal chemical modification, helping to preserve enzymatic activity. The approach yields favorable Michaelis-Menten constants (Kₘᵃᵖᵖ = 0.67 mM) and enables pesticide detection at nanomolar concentrations. The main advantages include simplicity and the ability to precisely pattern the enzyme layer, though potential photodamage to the enzyme during polymerization requires careful optimization of UV exposure conditions [7].

Emerging Orientation-Preserving Immobilization Strategies

Recent innovative approaches have focused on preserving the native orientation and membrane association of AChE to maintain its maximal biological activity. The development of right-side-out-oriented red blood cell membrane-coated electrochemical biosensors (ROCMCBs) represents a significant advancement in this direction. This methodology employs immunoaffinity interactions to orient red blood cell membranes on electrode surfaces, specifically exposing the extracellular domain of membrane-anchored AChE [9].

The ROCMCB platform demonstrates several advantages over conventional methods: it fully exposes AChE binding sites by controlling membrane orientation, maintains the enzyme's natural conformation as a peripheral membrane-anchoring protein, and preserves optimal interaction capabilities with inhibitors and substrates. This approach has enabled exceptional sensitivity for detecting AChE inhibitors like huperzine A, with limits of detection reaching 0.41 pmol/L. Furthermore, this bio-mimetic strategy has facilitated the rapid identification and evaluation of six potentially active anti-Alzheimer's compounds (baicalin, geniposide, gastrodin, berberine, rhynchophylline, and senkyunolide A) from traditional Chinese medicines, highlighting its utility in drug discovery applications [9].

The implementation of this orientation-controlled immobilization requires specific technical steps: (1) isolation of red blood cell membranes through sequential centrifugation and osmotic lysis; (2) antibody-mediated surface functionalization using CD47 intracellular primary antibody; (3) oriented assembly through immunoaffinity between gold-conjugated secondary antibodies and membrane-bound primary antibodies; and (4) comprehensive validation using immunofluorescence techniques with confocal laser scanning microscopy to confirm proper orientation [9].

This application note delineates the principal advantages of immobilized enzyme systems over their free enzyme counterparts, with a specific focus on stability, reusability, and operational practicality. Framed within the context of advanced acetylcholinesterase (AChE) biosensor research for drug development and diagnostic applications, the document provides a comparative quantitative analysis, detailed experimental protocols for common immobilization techniques on electrode surfaces, and essential resource guidance to facilitate robust biocatalytic system development. The integration of immobilized AChE is highlighted as a critical enabling technology for enhancing the performance and reliability of electrochemical biosensors in pharmaceutical and clinical settings.

Enzyme immobilization, defined as the confinement or localization of enzymes to a distinct region of space with retention of their catalytic activities, has evolved into a powerful tool for biocatalyst engineering [11]. This technology addresses inherent limitations of free enzymes in solution, including limited operational stability, short shelf-life, challenges in recovery and reuse, and poor compatibility with continuous industrial processes [12]. Within the specific research domain of acetylcholinesterase (AChE)-based biosensors, immobilization is not merely a convenience but a fundamental requirement for creating durable, sensitive, and reusable analytical devices for drug discovery, environmental monitoring, and clinical diagnostics [13] [14]. This note systematically outlines the key advantages, provides actionable protocols, and curates essential tools for researchers developing next-generation immobilized enzyme systems.

Comparative Advantages of Immobilized Enzymes

The transition from free to immobilized enzymes confers significant benefits that enhance both the enzyme's intrinsic properties and its process integration capabilities. The table below provides a structured comparison of these advantages.

Table 1: Key Advantages of Immobilized Enzymes over Free Enzymes

| Advantage Category | Key Metrics & Performance Outcomes | Relevance to AChE Biosensors |

|---|---|---|

| Enhanced Stability | Increased resistance to temperature, pH, and organic solvents [12] [15]. Retained activity over extended storage periods [13]. | AChE@MnMOF platform showed superior stability and resistance to harsh environments compared to free AChE [13]. |

| Reusability & Recovery | Capability for multiple use cycles (often 10+ cycles). Easy separation from reaction mixture, preventing product contamination [12] [16]. | Enables continuous or repeated batch operations; simplifies enzyme separation, reducing process costs [12]. |

| Process Control & Practicality | Suitable for continuous flow reactors. Improved control over reaction parameters. Reduced labor input and minimized reaction time [16] [17]. | Fundamental for constructing electrochemical sensors for repeated or continuous monitoring of anticholinesterase drugs or pesticides [14]. |

| Functional Efficiency | Potential for increased enzyme-substrate ratio. Improved specificity and product purity in some cases [17]. | Confinement on an electrode surface can enhance local substrate concentration and signal transduction efficiency [18]. |

| Economic Viability | Reduced enzyme consumption over time. Lower costs associated with production, labor, and downstream processing [16]. | Reuse of the biosensing interface drastically lowers the cost-per-analysis for high-throughput drug screening [19]. |

Experimental Protocols for Acetylcholinesterase Immobilization

The selection of an immobilization strategy is application-specific. Below are detailed protocols for two highly relevant techniques used in AChE biosensor fabrication: Covalent Binding on Metal-Organic Frameworks (MOFs) and Physical Adsorption on Prussian Blue-Modified Electrodes.

Protocol: Covalent Immobilization of AChE on a Squaric Acid-Based MnMOF Platform

This protocol describes a gentle, one-pot method for constructing an AChE-immobilized platform (AChE@MnMOF) that demonstrates superior stability for electrochemical sensing [13].

1. Research Reagent Solutions

- Squaric Acid Sodium Solution (0.1 M): Dissolve 0.1 M of squaric acid in 0.2 M NaOH solution using ultrasonication.

- Manganese Chloride Solution (0.1 M): Prepare in a 15% (v/v) ethanol solution.

- Acetylcholinesterase (AChE) Stock: Dissolve 1 mg of AChE in 0.5 mL of the prepared squaric acid sodium solution.

- Buffer: 0.1 M Phosphate Buffered Saline (PBS), pH 7.4.

2. Step-by-Step Workflow

- Enzyme-Carrier Mixing: Combine the 0.5 mL AChE-squaric acid solution with 0.5 mL of the 0.1 M manganese chloride tetrahydrate solution.

- Synthesis Incubation: Allow the mixture to stand undisturbed at room temperature for 60 minutes to facilitate the formation of the AChE@MnMOF composite.

- Washing and Harvesting: Centrifuge the suspension (e.g., 5000 rpm for 5 min) and carefully discard the supernatant. Wash the resulting AChE@MnMOF pellet three times with 0.1 M PBS (pH 7.4) to remove any unbound enzyme.

- Storage: Re-suspend the final AChE@MnMOF product in PBS (pH 7.4) and store at 4°C when not in use.

3. Critical Experimental Parameters

- pH: The reaction must be conducted under mild pH conditions to preserve enzyme activity.

- Temperature: Room temperature (approx. 25°C) synthesis is crucial to prevent enzyme denaturation.

- Control: Synthesize the MnMOF carrier without AChE in parallel to serve as a control for subsequent experiments.

The following diagram illustrates the experimental workflow and the charge repulsion sensing mechanism of the resulting AChE@MnMOF platform.

Protocol: Co-Immobilization of AChE and BChE via Adsorption for Broad-Spectrum Insecticide Screening

This protocol details the co-immobilization of AChE and Butyrylcholinesterase (BChE) on a modified electrode surface via adsorption and diazonium chemistry, enabling the broad-spectrum detection of insecticides [20].

1. Research Reagent Solutions

- Electrode Modifier: 4-aminothiophenol monolayer for diazonium chemistry.

- Prussian Blue Stabilizer: Copper-containing Prussian blue, electrodeposited on the modified electrode.

- Enzyme Solution: A mixture of AChE and BChE in a suitable buffer (e.g., Tris-HCl, pH 8.0).

- Buffer: 0.1 M Tris-HCl buffer, pH 8.0.

2. Step-by-Step Workflow

- Electrode Modification: Electrodeposit a stabilized, copper-containing Prussian blue layer onto an electrode pre-coated with a 4-aminothiophenol monolayer.

- Enzyme Immobilization: Drop-cast the solution containing both AChE and BChE onto the modified electrode surface.

- Adsorption Incubation: Incubate the electrode at 4°C for 12-24 hours to allow for physical adsorption and stable layer formation.

- Rinsing: Gently rinse the electrode with cold Tris-HCl buffer (pH 8.0) to remove any loosely bound enzyme molecules.

3. Critical Experimental Parameters

- Incubation Time: A prolonged incubation period (12-24 hours) is often necessary to achieve strong adsorption and minimize enzyme leaching.

- Temperature: Incubation at 4°C helps maintain enzyme stability during the process.

- Enzyme Ratio: The optimal ratio of AChE to BChE should be empirically determined for the target analytes.

The Scientist's Toolkit: Essential Research Reagent Solutions

Successful development of immobilized enzyme systems requires careful selection of materials. The following table catalogs key reagents and their functions in the context of AChE immobilization for biosensing.

Table 2: Essential Research Reagents for AChE Immobilization Studies

| Reagent / Material | Function & Rationale | Example from Literature |

|---|---|---|

| Metal-Organic Frameworks (MOFs) | Nano-porous carriers with high surface area for high enzyme loading; tailorable pore channels [13] [18]. | MnMOF with squaric acid ligand used for stable AChE immobilization under mild conditions [13]. |

| Prussian Blue & Derivatives | Inorganic matrices for electrode modification; excellent electrocatalytic properties and stability [20]. | Copper-containing Prussian blue used for co-immobilization of AChE and BChE [20]. |

| Chitosan & Other Natural Polymers | Biocompatible, biodegradable, and cost-effective supports with functional groups for covalent/ionic attachment [15]. | Chitosan is a popular choice due to its cationic nature and ease of functionalization. |

| Glutaraldehyde | A common homobifunctional crosslinker; forms Schiff bases with amino groups (e.g., lysine) on enzymes for covalent binding [15]. | Used as a linker molecule to activate carrier surfaces for stable covalent enzyme attachment [15]. |

| Acetylthiocholine (ATCh) | Synthetic substrate for AChE; enzymatic hydrolysis produces electroactive thiocholine (TCh+), enabling amperometric detection [13] [14]. | Used as the substrate in the AChE@MnMOF sensor; TCh+ production leads to a measurable charge repulsion effect [13]. |

| Ru(NH₃)₆³⁺ (Rubhex) | Positively charged electrochemical probe; used in "turn-on" sensing mechanisms based on charge repulsion with TCh+ [13]. | Served as the core signaling probe in the charge-repulsion-based AChE@MnMOF sensor [13]. |

The strategic relationships between these reagents and the core components of a biosensor are visualized below.

The immobilization of enzymes, particularly acetylcholinesterase, presents a transformative approach for advancing biosensor technology in drug development. The documented advantages in stability, reusability, and overall practicality underscore its critical role in transitioning from laboratory curiosities to robust, commercially viable analytical tools. The protocols and reagent solutions provided herein offer a foundational framework for researchers to design and implement high-performance immobilized enzyme systems, thereby accelerating innovation in pharmaceutical analytics and diagnostic applications.

The performance of an electrochemical biosensor is fundamentally dictated by the properties of the supporting material used to immobilize the biological recognition element. For acetylcholinesterase (AChE)-based biosensors, the support matrix must not only secure the enzyme but also actively preserve its activity and facilitate efficient electron transfer. Among the critical material properties, biocompatibility, specific surface area, and ease of functionalization emerge as three pillars essential for developing reliable and sensitive interfaces. This document details the core principles and experimental protocols for characterizing these properties, providing a framework for advancing AChE immobilization techniques in electrochemical biosensing.

Core Material Properties and Characterization

The interplay between a material's intrinsic properties dictates its suitability as a platform for AChE immobilization. The table below summarizes the key properties, their impact on biosensor function, and standard characterization techniques.

Table 1: Core Support Material Properties for AChE Immobilization

| Property | Impact on Biosensor Performance | Common Characterization Methods |

|---|---|---|

| Biocompatibility | Preserves enzymatic structure and activity; minimizes denaturation; ensures operational stability. [21] [13] | Enzyme activity assays; viability/staining assays for living cells; monitoring electrochemical signal retention over time. |

| High Surface Area | Increases enzyme loading capacity; enhances signal-to-noise ratio; improves catalytic efficiency. [21] [22] | Brunauer-Emmett-Teller (BET) analysis; Scanning Electron Microscopy (SEM). |

| Functionalization | Enables strong, stable enzyme attachment (e.g., covalent binding); introduces desired chemical groups for specific interactions. [23] [22] | Fourier Transform Infrared Spectroscopy (FTIR); X-ray Photoelectron Spectroscopy (XPS). |

Experimental Protocols for Material Evaluation

Protocol: Functionalization of Renewable Carbon via Acid Treatment

This protocol outlines the functionalization of renewable carbon (RC) to create a highly functionalized platform (RCF) ideal for AChE binding, based on a validated biosensor design. [23]

- Principle: Acid treatment with a sulfonitric mixture introduces oxygen-containing functional groups (e.g., carboxyl, hydroxyl) onto the carbon surface, enhancing its hydrophilicity and providing anchoring sites for enzyme immobilization.

Materials:

- Renewable Carbon (RC) powder, derived from biomass pyrolysis. [23]

- Nitric Acid (HNO₃) and Sulfuric Acid (H₂SO₄).

- Ultrasonic probe.

- Filtration setup with 0.45 µm nylon membrane.

- Ultrapure water.

Procedure:

- In a fume hood, slowly add a 1:3 (v/v) mixture of HNO₃ to H₂SO₃ in a suitable glass container under vigorous stirring to create the sulfonitric solution.

- Gradually add the RC powder to the acid mixture. Continue stirring for the desired reaction time (e.g., 2-4 hours).

- Carefully filter the resulting functionalized carbon (RCF) through a 0.45 µm nylon membrane.

- Wash the RCF cake repeatedly with ultrapure water until the filtrate reaches a neutral pH to ensure complete acid removal.

- Disperse the final RCF product in ultrapure water at a concentration of 1.0 mg mL⁻¹ using an ultrasonic probe for 2 sets of 10 minutes to create a homogeneous suspension.

Protocol: Construction of an AChE Biosensor with a Metal-Organic Framework (MnMOF) Platform

This protocol describes a gentle method for constructing an AChE-immobilized platform (AChE@MnMOF) that demonstrates superior stability and resistance to harsh environments compared to free enzyme. [13]

Principle: A metal-organic framework (MnMOF) synthesized from squaric acid and manganese ions under mild conditions provides a porous, high-surface-area carrier for AChE. The resulting platform protects the enzyme and can be integrated into an electrochemical sensor based on charge repulsion effects.

Materials:

- Acetylcholinesterase (AChE) from Electrophorus electricus (e.g., Type VI-S, lyophilized powder).

- Squaric acid, Sodium Hydroxide (NaOH), Manganese(II) chloride tetrahydrate (MnCl₂·4H₂O).

- Ethanol.

- Phosphate Buffered Saline (PBS, 0.1 M, pH 7.4).

- Fluorine-doped Tin Oxide (FTO) or Glassy Carbon Electrode (GCE).

Procedure:

- Synthesis of AChE@MnMOF: a. Prepare a 0.1 M squaric acid sodium solution by dissolving squaric acid in a 0.2 M NaOH solution with ultrasonication. b. Add 1 mg of AChE to 0.5 mL of the prepared squaric acid sodium solution. c. In a separate vial, prepare a 0.1 M solution of MnCl₂·4H₂O in a 15% ethanol solution. d. Mix the two solutions and allow the reaction to proceed at room temperature for a defined period (e.g., 2 hours). The resulting composite is AChE@MnMOF.

- Electrode Modification and Biosensor Assembly: a. Polish the bare GCE (or clean the FTO electrode) following standard electrochemical preparation procedures. b. Deposit a precise aliquot (e.g., 5-10 µL) of the AChE@MnMOF suspension onto the electrode surface. c. Allow the modified electrode to dry at room temperature, forming a stable film.

Diagram: Experimental Workflow for AChE Biosensor Construction

The Scientist's Toolkit: Essential Research Reagents

The following table lists key materials used in the development of high-performance AChE biosensors, as cited in recent literature.

Table 2: Essential Reagents for AChE Biosensor Development

| Material / Reagent | Function / Rationale | Example Application |

|---|---|---|

| Renewable Carbon (RC) [23] | Sustainable, carbon-rich platform derived from biomass; moderate surface area and surface functional groups enable effective enzyme binding. | Base material for functionalization and AChE immobilization in pesticide detection. |

| SnO₂ Nanoparticles (NPs) [21] | n-type semiconductor; provides high surface area, good biocompatibility, and strong electrocatalytic activity. | Component of nanocomposite (with carboxylic graphene) for enhanced electron transfer. |

| Carboxylic Graphene (CGR) [21] | Graphene oxide with -COOH groups; offers large surface area, excellent conductivity, and functional groups for covalent enzyme attachment. | Used with SnO₂ NPs and Nafion to form a highly conductive nanocomposite film. |

| Nafion (NF) [21] | Perfluorosulfonated ionomer; acts as a protective membrane, provides chemical inertness, and helps stabilize the modified electrode surface. | Protective membrane and dispersion matrix for nanocomposites on the electrode. |

| Squaric Acid [13] | Organic ligand for MOF synthesis; allows for construction of the immobilization platform under mild, enzyme-friendly conditions. | Ligand for constructing the MnMOF enzyme carrier (AChE@MnMOF). |

| Manganese Ions (Mn²⁺) [13] | Metal center for MOF coordination; forms stable structures with squaric acid, creating a porous support for AChE. | Metal center for the MnMOF in the AChE immobilization platform. |

| Chitosan (CS) [21] | Natural biopolymer; used as a hydrogel for enzyme encapsulation, provides biocompatibility and enhances electron shuttling. | Hydrogel matrix for entrapping AChE on the surface of modified electrodes. |

The strategic selection and optimization of support materials based on biocompatibility, surface area, and functionalization potential are paramount for pushing the boundaries of AChE-based biosensors. The protocols and data presented herein provide a concrete foundation for researchers to engineer advanced immobilization platforms. By meticulously controlling these material properties, scientists can develop next-generation biosensors with enhanced sensitivity, stability, and application range, from environmental pesticide monitoring to neurodegenerative disease research.

Cutting-Edge Immobilization Methodologies and Their Real-World Applications

Physical Adsorption and Entrapment on Porous Silicon and other Nanomatrices

The immobilization of enzymes, such as acetylcholinesterase (AChE), is a critical technique for enhancing the stability and reusability of biocatalysts in industrial processes and biosensing applications [24]. Among the various support matrices available, porous silicon (PSi) and electrospun nanofibers stand out due to their high surface area-to-volume ratio, tunable porosity, and biocompatibility [24] [25]. PSi, in particular, with its interconnected pore network and easily modifiable surface chemistry, is ideally suited for enzyme anchoring, leading to improved operational stability and catalytic performance [26]. These immobilization strategies are pivotal in the development of robust biosensors and biocatalytic systems, especially in the context of drug development where AChE is a key target.

This document provides detailed application notes and protocols for the physical adsorption and entrapment of AChE on porous silicon and within electrospun nanofibers, framed within a broader thesis on AChE immobilization techniques for electrodes.

Acetylcholinesterase Immobilization on Porous Silicon

Physical Adsorption on Porous Silicon

Principle: Physical adsorption relies on non-covalent interactions (e.g., van der Waals forces, hydrophobic interactions, hydrogen bonding) between the enzyme and the porous silicon surface. This method is simple and preserves enzyme activity by avoiding harsh chemical reactions [24].

Protocol:

- PSi Substrate Preparation: Fabricate a mesoporous silicon layer (average pore size below 15 nm) on a p-type silicon wafer via electrochemical anodization in an HF-based electrolyte [26].

- Surface Activation: Treat the freshly etched, hydrogen-terminated PSi surface with a mild oxidizing agent or piranha solution to create a hydrophilic, hydroxyl-rich surface, which enhances enzyme binding [26].

- Enzyme Immobilization: Incubate the activated PSi substrate in a phosphate buffer (pH 7-8) containing AChE (e.g., from Electrophorus electricus) for a defined period (e.g., 1-2 hours) at room temperature [24].

- Washing: Gently rinse the PSi-AChE conjugate with buffer to remove any loosely bound enzyme.

Performance Data of Adsorbed AChE: Table 1: Characteristic performance data for AChE immobilized on PSi via physical adsorption.

| Parameter | Performance | Experimental Conditions |

|---|---|---|

| Activity Retention | ~50% retained activity | After immobilization, assessed via Ellman's assay [24] |

| Thermal Stability | Stable up to 90°C | Retained activity after exposure to high temperature [24] |

| pH Stability | Broad range (4–9) | Retained activity across pH values [24] |

| Reusability | Up to 3 cycles | Enzyme activity retained over repeated use [24] |

| Shelf Life | 44 days | Storage stability at 4°C [24] |

Covalent Immobilization on Modified Porous Silicon

Principle: Covalent attachment involves the formation of stable bonds (e.g., amide bonds) between functional groups on the enzyme and a chemically modified PSi surface. This method typically provides higher stability and prevents enzyme leaching [26].

Two primary strategies for covalent attachment are highlighted below:

Figure 1: Two chemical pathways for covalent immobilization of AChE on a porous silicon surface.

Protocol for Path A (Hydrosilylation and Amine Coupling):

- Hydrosilylation: React the hydrogen-terminated PSi surface with undecylenic acid (an ω-alkenoic acid) under inert atmosphere to form a stable carboxyl-terminated (PSi-COOH) monolayer via Si-C bonds [26].

- Activation: Incubate the PSi-COOH surface with a mixture of N-hydroxysuccinimide (NHS) and N-ethyl-N'-(3-dimethylaminopropyl)-carbodiimide (EDC) in water to activate the carboxyl groups, forming reactive succinimidyl esters (PSi-COOSuc) [26].

- Enzyme Coupling: Expose the activated surface to a solution of AChE. The primary amine groups on the enzyme's lysine residues will react with the esters to form stable amide bonds [26].

- Washing: Rinse thoroughly with buffer to remove non-covalently bound enzyme.

Protocol for Path B (Silanization and Carboxyl Coupling):

- Hydroxylation: Oxidize the hydrogen-terminated PSi in a piranha solution to create a homogeneous hydroxyl-terminated (Si-OH) surface [26].

- Silanization: React the hydroxylated PSi with 3-aminopropyltriethoxysilane (APTES) to form an amine-terminated (PSi-NH₂) surface via siloxane (Si-O-Si) linkages [26].

- Enzyme Coupling: Incubate the PSi-NH₂ surface with AChE in the presence of NHS/EDC. The carbodiimide chemistry activates the carboxylic acid groups on the enzyme (e.g., from aspartic or glutamic acid residues), which then form amide bonds with the surface amine groups [26].

- Washing: Rinse thoroughly with buffer.

Characterization: Success of surface modification and enzyme immobilization can be confirmed by Fourier Transform Infrared Spectroscopy (FTIR), which detects characteristic bonds (e.g., amide I and II bands), and by contact angle measurements, which reveal changes in surface wettability and can infer enzyme orientation [26].

Enzyme Entrapment in Electrospun Nanofibers

Principle: Enzyme entrapment and encapsulation involve incorporating the enzyme within a three-dimensional polymer network during the electrospinning process. This method protects the enzyme from harsh environmental conditions and minimizes leaching [25].

Figure 2: Workflow for encapsulating enzymes within electrospun nanofibers.

Protocol:

- Polymer Solution Preparation: Dissolve a suitable polymer (e.g., poly(methyl methacrylate) - PMMA, sodium alginate, poly(vinyl chloride)) in an appropriate organic solvent [25].

- Enzyme-Polymer Mixture: Gently mix the AChE enzyme solution into the polymer solution to achieve a homogeneous dispersion, avoiding conditions that could denature the enzyme.

- Electrospinning: Load the mixture into a syringe. Use a syringe pump to feed the solution through a metallic needle charged with a high voltage (typically 10-25 kV). The charged jet is drawn toward a grounded collector, solidifying into continuous nanofibers with the enzyme encapsulated within [25].

- Storage: Store the resulting nanofiber mat in a dry and cool environment.

Performance Advantages: Studies with other enzymes, like laccase, demonstrate the benefits of encapsulation. Laccase encapsulated in PMMA/Fe₃O₄ nanofibers achieved 100% immobilization yield and retained 90% of its initial activity after 40 days of storage, outperforming covalently bound enzymes [25]. Similarly, horseradish peroxidase (HRP) encapsulated in sodium alginate/poly(vinyl chloride) nanofibers was highly effective, degrading over 80% of specific pharmaceuticals in wastewater within 24 hours [25].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key reagents, materials, and equipment used in AChE immobilization protocols.

| Item | Function / Role | Example Use Case |

|---|---|---|

| Porous Silicon (PSi) | High-surface-area support matrix | Substrate for physical adsorption and covalent attachment of AChE [24] [26]. |

| Acetylcholinesterase (AChE) | Target enzyme for immobilization | Biocatalyst for hydrolysis of acetylthiocholine; model for inhibitor studies [24] [26]. |

| Undecylenic Acid | Provides surface carboxyl groups | Used in hydrosilylation for covalent immobilization path A [26]. |

| 3-Aminopropyltriethoxysilane (APTES) | Provides surface amine groups | Used in silanization for covalent immobilization path B [26]. |

| NHS & EDC | Crosslinking/coupling agents | Activates carboxyl groups for amide bond formation with enzyme amines [26]. |

| Electrospinning Polymers (e.g., PMMA) | Nanofiber matrix for entrapment | Forms the protective scaffold for enzyme encapsulation [25]. |

| Acetylthiocholine Iodide | Enzyme substrate | Used in Ellman's assay to measure AChE activity [24]. |

| 5,5'-Dithiobis-(2-nitrobenzoic acid) (DTNB) | Chromogenic agent (Ellman's reagent) | Produces a yellow-colored product upon reaction with thiocholine, allowing spectrophotometric activity measurement [26]. |

Comparative Analysis and Application Notes

Selection Guide:

- Physical Adsorption: Best for rapid prototyping and applications where minimal surface modification is desired. Its main drawbacks are potential enzyme leaching and lower stability under harsh conditions [24].

- Covalent Attachment: Ideal for applications requiring high operational stability and reusability, such as reusable biosensor electrodes or flow-through bioreactors. The chemical modification process is more complex and requires careful optimization to maintain enzyme activity [26].

- Entrapment/Encapsulation: Superior for protecting enzymes from denaturation and for use in harsh environments (e.g., organic solvents, extreme pH). It is well-suited for wastewater treatment and controlled release systems [25].

Activity Assay Protocol (Ellman's Method): The activity of free and immobilized AChE can be quantified using Ellman's assay [24] [26].

- Prepare a reaction mixture containing acetylthiocholine iodide (substrate) and DTNB (Ellman's reagent) in phosphate buffer (pH ~8.0).

- Add the AChE sample (free enzyme or immobilized substrate).

- Immediately monitor the increase in absorbance at 412 nm over time using a spectrophotometer. The rate of increase is proportional to the enzyme activity, as AChE hydrolyzes acetylthiocholine to release thiocholine, which reacts with DTNB to form 2-nitro-5-thiobenzoate (yellow).

Conclusion: The choice of immobilization technique—physical adsorption on porous silicon, covalent attachment on functionalized PSi, or entrapment within electrospun nanofibers—depends on the specific application requirements for stability, reusability, and activity retention. Porous silicon offers a versatile and high-capacity platform, particularly for biosensing applications within electrode design. In contrast, electrospun nanofibers provide a robust protective environment for enzymes in challenging process conditions. These advanced immobilization strategies significantly enhance the practicality of AChE and other enzymes in industrial biocatalysis, pharmaceutical screening, and environmental monitoring.

Covalent Immobilization on Functionalized Electrodes and Nanoparticle Composites

Application Note: Advanced Immobilization Platforms for Enhanced Biosensing

This application note details specialized protocols for covalent immobilization of acetylcholinesterase (AChE) on functionalized electrodes and nanoparticle composites, supporting ongoing thesis research on biosensor development for environmental and pharmaceutical applications. Covalent immobilization provides superior enzyme stability, prevents enzyme leakage, and maintains bioactivity under operational conditions, making it essential for reliable biosensor performance [27]. These techniques enable the creation of robust sensing platforms for detecting organophosphorus pesticides, carbamate insecticides, pharmaceutical agents, and heavy metals through AChE inhibition mechanisms [13] [28] [29].

The protocols described herein leverage nanomaterial-enhanced surfaces to address critical challenges in biosensor fabrication, including inefficient electron transfer, enzyme denaturation on metal surfaces, and limited operational stability [30] [31]. By creating stable covalent linkages between enzyme functional groups and activated support surfaces, these methods significantly improve biosensor lifespan while maintaining high catalytic efficiency.

Comparative Performance of Immobilization Platforms

Table 1: Analytical performance of AChE biosensors using different covalent immobilization strategies

| Immobilization Platform | Target Analyte | Linear Range | Detection Limit | Stability/Reusability | Reference |

|---|---|---|---|---|---|

| MnMOF-squaric acid | Chlorazophos | Not specified | 0.532 ng/mL | Enhanced stability vs. free AChE; resistant to harsh conditions | [13] |

| Electrodeposited Au nanoparticles | Carbofuran | Not specified | nM concentrations | Stable response; reusable | [31] |

| Screen-printed carbon electrode (direct covalent) | Arsenic(III) | 1×10⁻⁸ to 1×10⁻⁷ M | 1.1×10⁻⁸ M | RSD <4%; good reproducibility | [28] |

| 3D-printed flow-through reactor | Carbofuran | 10 nM - 0.1 μM | 10 nM | Easy mounting; low-cost replaceable parts | [29] |

| 3D-printed flow-through reactor | Donepezil | 1.0 nM - 1.0 μM | 1.0 nM | Suitable for point-of-care testing | [29] |

Table 2: Advantages and limitations of different covalent immobilization approaches

| Immobilization Method | Advantages | Limitations | Optimal Applications |

|---|---|---|---|

| Metal-Organic Frameworks (MOFs) | High surface area, tunable porosity, protective microenvironment | Strict synthesis conditions, potential coordination bond disruption | Sensitive detection systems requiring enzyme protection |

| Gold Nanoparticles | Enhanced electron transfer, roughened surface for better enzyme attachment | Higher cost, complex characterization | Fundamental studies on electron transfer mechanisms |

| Screen-printed Electrodes | Disposable use, cost-effective, reproducible mass production | Limited surface area, lower enzyme loading | Field-deployable sensors, single-use applications |

| Flow-through Reactors | Continuous operation, sample processing capability | More complex instrumentation, potential for clogging | Automated screening systems, continuous monitoring |

Protocol 1: AChE Immobilization on MnMOF Platform for Charge Repulsion-Based Detection

Principle

This protocol describes the covalent immobilization of AChE on squaric acid-based manganese metal-organic frameworks (MnMOF) for electrochemical detection of organophosphorus pesticides (OPs) based on charge repulsion effects [13]. The positively charged thiocholine (TCh) produced from acetylthiocholine hydrolysis creates charge repulsion with an equally positively charged electrochemical probe (Ru[(NH₃)₆]³⁺), reducing the electrochemical signal. OPs inhibit AChE activity, reducing TCh production and consequently weakening the repulsion effect, thereby restoring electrical signals in a concentration-dependent manner.

Materials and Reagents

Table 3: Essential research reagents for MnMOF immobilization protocol

| Reagent/Material | Specifications | Function in Protocol |

|---|---|---|

| Acetylcholinesterase (AChE) | Electric eel, Type III, ≥1000 U/mg | Biological recognition element for pesticide detection |

| Squaric acid (Quadratic acid) | 0.1 M in 0.2 M NaOH | Organic ligand for MOF construction |

| Manganese chloride tetrahydrate | 0.1 M in 15% ethanol | Metal ion source for MOF coordination |

| Acetylthiocholine (ATCh) | Substrate for enzymatic reaction | Enzyme substrate producing electroactive thiocholine |

| Ru[(NH₃)₆]³⁺ | Electrochemical probe | Positively charged mediator for charge repulsion detection |

| Fluorine-doped Tin Oxide (FTO) electrodes | Conducting transparent electrodes | Electrode substrate for biosensor assembly |

| Phosphate buffer | 0.1 M, pH 7.4 | Optimal pH environment for enzyme activity |

Step-by-Step Procedure

Synthesis of AChE@MnMOF

- Ligand Solution Preparation: Dissolve 0.1 M squaric acid in 0.2 M NaOH solution using ultrasonication for 5 minutes until completely dissolved.

- Enzyme Addition: Add 1 mg AChE to 0.5 mL of the prepared squaric acid sodium solution. Mix gently by swirling to avoid enzyme denaturation.

- Metal Solution Preparation: Dissolve 0.1 M manganese chloride tetrahydrate in 15% ethanol solution.

- Mixing and Reaction: Combine the enzyme-ligand solution with 0.5 mL manganese chloride solution. Allow the mixture to react at room temperature for 2 hours without disturbance.

- Collection and Washing: Centrifuge the resulting AChE@MnMOF composite at 5000 rpm for 10 minutes. Discard supernatant and resuspend in 0.1 M phosphate buffer (pH 7.4). Repeat washing twice.

Electrode Modification and Biosensor Assembly

- FTO Cleaning: Clean FTO electrodes sequentially with acetone, ethanol, and deionized water using ultrasonication for 10 minutes each.

- Composite Deposition: Drop-cast 10 μL of AChE@MnMOF suspension onto the pre-cleaned FTO electrode surface.

- Drying: Allow the modified electrode to dry overnight at 4°C under controlled humidity.

- Storage: Store the prepared biosensor at 4°C in dry conditions when not in use.

Inhibition Assay for Pesticide Detection

- Baseline Measurement: Record the amperometric response in 0.1 M phosphate buffer (pH 7.4) containing 0.3 mM ATCh and 50 μM Ru[(NH₃)₆]³⁺ at applied potential of -0.25 V vs. Ag/AgCl.

- Inhibition Step: Immerse the biosensor in sample containing target OP pesticide for 15 minutes.

- Signal Measurement: Re-measure the amperometric response under identical conditions as baseline.

- Quantification: Calculate inhibition percentage using the formula: % Inhibition = [(I₀ - I)/I₀] × 100, where I₀ and I are currents before and after inhibition.

Critical Parameters and Optimization

- Enzyme Loading: 1 mg AChE per mL of ligand solution provides optimal activity retention while preventing overcrowding.

- pH Optimization: pH 7.4 phosphate buffer maintains enzyme stability and activity.

- Inhibition Time: 15-minute inhibition provides sufficient sensitivity while maintaining practical analysis time.

- Temperature Control: All procedures should be performed at 4°C when handling enzyme solutions to prevent denaturation.

Protocol 2: Electrodeposited Gold Nanoparticle Platform for Enhanced AChE Stabilization

Principle

This protocol utilizes electrodeposited gold nanoparticles (AuNPs) to create a roughened electrode surface that enhances AChE immobilization and stabilizes enzyme activity [31]. The nanostructured surface increases effective surface area and provides a favorable microenvironment for enzyme orientation, significantly improving electron transfer efficiency compared to planar gold electrodes. The immobilized AChE catalyzes acetylthiocholine hydrolysis to thiocholine, which is electrochemically oxidized at the electrode surface, enabling detection of AChE inhibitors through signal reduction.

Materials and Reagents

Table 4: Essential research reagents for AuNP immobilization protocol

| Reagent/Material | Specifications | Function in Protocol |

|---|---|---|

| Hydrogen tetrachloroaurate | 99.99% purity | Gold precursor for nanoparticle synthesis |

| Gold wire electrode | 99.99% purity, 0.2 mm diameter | Working electrode substrate |

| Phosphate buffer saline | 0.1 M, pH 7.4 | Electrochemical measurement buffer |

| Acetylthiocholine chloride | ≥99% purity | Enzyme substrate |

| Aluminum oxide sanding gel | 0.3 μm and 0.05 μm | Electrode polishing material |

| Potassium chloride | Analytical grade | Supporting electrolyte |

Step-by-Step Procedure

Electrode Pretreatment

- Mechanical Polishing: Polish gold wire electrodes sequentially with 0.3 μm and 0.05 μm aluminum oxide sanding gel to create a mirror-finish surface.

- Electrochemical Cleaning: Perform cyclic voltammetry in 0.5 M H₂SO₄ from -0.2 to +1.5 V (vs. Ag/AgCl) at 100 mV/s until stable voltammogram is obtained.

- Rinsing: Rinse thoroughly with deionized water between each polishing step and after electrochemical cleaning.

Gold Nanoparticle Electrodeposition

- Solution Preparation: Prepare electrodeposition solution containing 0.5 mM HAuCl₄ in 0.1 M KCl.

- Electrodeposition: Apply constant potential of -0.2 V (vs. Ag/AgCl) for 300 seconds to the pre-cleaned gold electrode in the deposition solution under gentle stirring.

- Characterization: Monitor the deposition process by observing the color change from metallic gold to dull reddish color, indicating successful nanoparticle formation.

- Rinsing and Drying: Rinse the AuNP-modified electrode with deionized water and dry under nitrogen stream.

AChE Immobilization

- Enzyme Adsorption: Incubate the AuNP-modified electrode in AChE solution (0.1 mg/mL in pH 7.4 phosphate buffer) for 12 hours at 4°C.

- Washing: Gently rinse with cold phosphate buffer to remove loosely adsorbed enzyme.

- Storage: Store the prepared biosensor at 4°C in phosphate buffer when not in use.

Amperometric Measurement

- Experimental Setup: Use conventional three-electrode system with AChE-AuNP electrode as working electrode, Ag/AgCl reference electrode, and platinum counter electrode.

- Measurement Conditions: Apply potential of +0.6 V (vs. Ag/AgCl) in stirring phosphate buffer solution (pH 7.4).

- Substrate Addition: Add acetylthiocholine aliquots to desired concentration (typically 0.1-0.5 mM final concentration).

- Signal Recording: Record steady-state oxidation current (typically within 30-60 seconds).

Critical Parameters and Optimization

- Electrodeposition Potential: -0.2 V provides optimal nanoparticle size distribution and surface coverage.

- Enzyme Concentration: 0.1 mg/mL AChE provides monolayer coverage without excessive multilayer formation.

- Adsorption Time: 12-hour incubation ensures sufficient enzyme loading while maintaining activity.

- Applied Potential: +0.6 V enables thiocholine oxidation while minimizing interfering reactions.

Troubleshooting and Technical Considerations

Common Implementation Challenges

- Low Enzyme Activity Retention: Ensure proper pH control during immobilization (pH 7.0-7.5) and avoid dehydration of enzyme layer. For MOF-based platforms, verify that metal ions do not denature the enzyme by testing different metal-to-ligand ratios [13].

- High Background Current: Implement additional blocking steps with ethanolamine or bovine serum albumin (BSA) after enzyme immobilization to cover unreacted functional groups [27].

- Poor Reproducibility: Standardize electrode pretreatment procedures precisely and control nanoparticle deposition parameters rigorously. For AuNP platforms, ensure consistent electrodeposition time and potential [31].

- Signal Drift: Allow sufficient stabilization time after electrode modification (typically 24 hours at 4°C) before initial use. For flow-through systems, ensure stable flow rates and temperature control [29].

Validation Methods

- Activity Assay: Verify immobilized enzyme activity by comparing thiocholine production rates between free and immobilized AChE using Ellman's assay.

- Surface Characterization: Employ atomic force microscopy (AFM) to verify nanoparticle deposition and surface roughness [31].

- Electrochemical Characterization: Use cyclic voltammetry and electrochemical impedance spectroscopy to confirm successful enzyme immobilization and assess electron transfer efficiency.

- Stability Testing: Evaluate operational stability through repeated measurements over extended time periods and thermal stability by testing activity retention at different temperatures.

These application notes and protocols provide detailed methodologies for covalent immobilization of AChE on functionalized electrodes and nanoparticle composites, supporting advanced biosensor development for thesis research. The MnMOF platform offers exceptional enzyme stabilization against temperature and organic solvent denaturation, while the AuNP-enhanced electrode significantly improves electron transfer efficiency. Both platforms enable sensitive detection of AChE inhibitors with detection limits reaching nanomolar concentrations, making them suitable for environmental monitoring, food safety testing, and pharmaceutical applications.

The covalent immobilization approaches described herein provide superior performance compared to physical adsorption methods, particularly in terms of operational stability, reusability, and resistance to environmental perturbations. Researchers can select the appropriate platform based on specific application requirements, with MnMOF composites offering enhanced stability in harsh conditions and AuNP-modified electrodes providing superior electrochemical characteristics for sensitive amperometric detection.

Metal-Organic Frameworks (MOFs) as Advanced Enzyme Stabilization Platforms

Metal-organic frameworks (MOFs) have emerged as transformative materials for enzyme immobilization, addressing critical challenges in biocatalysis and biosensing. These porous crystalline structures, formed through coordination bonds between metal ions and organic ligands, provide an ideal microenvironment for stabilizing enzymes like acetylcholinesterase (AChE) while maintaining their catalytic efficiency [32] [33]. Their structural versatility, tunable porosity, and exceptional surface areas offer significant advantages over traditional immobilization supports, enabling breakthroughs in biosensor design, particularly for detecting environmental contaminants such as organophosphorus pesticides (OPs) [13] [18].

The integration of MOF technology with enzyme-based electrodes represents a paradigm shift in biosensing capabilities, overcoming inherent limitations of free enzymes including structural instability, sensitivity to environmental conditions, and poor reusability [32]. By providing protective nano-confinement and enhanced mass transfer pathways, MOF-based immobilization platforms significantly improve enzyme stability under operational conditions while enabling sophisticated sensing architectures for food safety monitoring, medical diagnostics, and environmental protection [32] [33].

MOF-Based Enzyme Immobilization Strategies

Fundamental Immobilization Approaches

The strategic immobilization of enzymes within MOF structures relies on precisely engineered interactions between the enzyme molecules and the porous framework. Researchers have developed multiple technical approaches to achieve optimal enzyme loading, activity retention, and stability enhancement, each with distinct advantages for specific applications.

Table 1: Comparison of MOF-Based Enzyme Immobilization Strategies

| Immobilization Method | Key Mechanism | Advantages | Limitations | Suitable MOF Types |

|---|---|---|---|---|

| In Situ Encapsulation | Co-precipitation or co-crystallization during MOF synthesis [34] [35] | High enzyme loading; minimal enzyme leaching; maximum protection | Harsh synthesis conditions may denature enzymes; limited control over MOF morphology | ZIF-8, ZIF-90, HKUST-1 [34] |

| Surface Immobilization | Covalent bonding or physical adsorption to pre-formed MOFs [35] | Preserves MOF crystallinity; simple procedure; suitable for large enzymes | Lower enzyme loading; potential enzyme leaching; limited protection | UIO-66-NH₂, MIL-101-NH₂ [35] |

| Pore Diffusion | Enzyme infiltration into pre-synthesized MOF pores [35] | Maintains enzyme native structure; mild conditions | Limited to enzymes smaller than MOF pores; potential leaching | Large-pore MOFs (MIL-100, MIL-101) [35] |

| Core-Shell Sequential Encapsulation | Controlled positioning of multiple enzymes through sequential addition [34] | Optimal spatial arrangement for cascade reactions; enhanced mass transfer | Complex synthesis optimization; requires compatibility between enzymes | ZIF-8, ZIF-90 [34] |

Advanced Design Considerations

Recent innovations in MOF-enzyme composite design have focused on overcoming the fundamental trade-offs between framework stability and enzyme activity. While MOF stability often requires harsh synthesis conditions, enzyme activity preservation necessitates mild environments [36]. Advanced strategies including defect engineering, biomimetic mineralization, and hierarchical pore architecture have successfully addressed these challenges, creating optimized microenvironments that maintain enzymatic conformation and catalytic efficiency [32] [37].

For AChE immobilization specifically, the selection of MOF composition and immobilization method must consider the enzyme's molecular dimensions, surface charge distribution, and sensitivity to organic solvents. The use of squaric acid-based MOFs synthesized under mild conditions has demonstrated exceptional success in maintaining AChE activity while providing enhanced stability against thermal denaturation and organic solvent exposure [13].

Application Notes: AChE-MOF Biosensors for Pesticide Detection

Operational Principles and Sensing Mechanisms

AChE-MOF biosensors for organophosphorus pesticide detection operate primarily through enzyme inhibition principles, where OPs irreversibly bind to the AChE active site, reducing catalytic activity proportionally to pesticide concentration [13] [18]. The detection methodology involves monitoring the enzymatic hydrolysis of acetylthiocholine iodide to thiocholine and acetic acid, with the electroactive thiocholine product generating measurable signals at the electrode interface [13] [28].

Innovative sensing mechanisms have significantly enhanced detection sensitivity and specificity. The charge repulsion effect represents a particularly advanced approach, where positively charged thiocholine electrostatically repels an equally charged redox probe (Ru[(NH₃)₆]³⁺), thereby decreasing electrochemical signal. OP inhibition reduces thiocholine production, consequently weakening this repulsion effect and restoring electrical signals in a quantifiable manner [13].

Performance Metrics and Real-World Applications

AChE-MOF biosensors have demonstrated exceptional analytical performance in both controlled laboratory settings and complex real-world samples. The AChE@MnMOF platform achieved a detection limit of 0.532 ng/mL for chlorazophos with satisfactory recoveries (88.15–107.86%) in actual samples including pears, cabbages, and tap water [13]. These biosensors maintain operational stability under challenging environmental conditions and exhibit significantly extended shelf life compared to free enzyme systems.

The practical implementation of these biosensing platforms has been enhanced through integration with disposable screen-printed carbon electrodes (SPCEs), which offer important advantages for field deployment including low cost, minimal sample volume requirements, and elimination of memory effects between measurements [38] [28]. This combination of sophisticated MOF-enzyme biocomposites with economical electrode platforms creates an optimal balance between analytical performance and practical applicability for environmental monitoring and food safety assurance.

Experimental Protocols

Protocol 1: Synthesis of AChE@MnMOF Biocomposite

Principle: This protocol describes the one-pot synthesis of acetylcholinesterase immobilized on squaric acid-based manganese MOF (AChE@MnMOF) under mild conditions to preserve enzymatic activity while ensuring robust immobilization [13].

Materials: