Advancing the Limits: Modern Strategies for Ultra-Trace Pesticide Analysis in Complex Matrices

This article provides a comprehensive analysis of contemporary strategies for optimizing detection limits in trace pesticide analysis, a critical challenge for researchers and food safety professionals.

Advancing the Limits: Modern Strategies for Ultra-Trace Pesticide Analysis in Complex Matrices

Abstract

This article provides a comprehensive analysis of contemporary strategies for optimizing detection limits in trace pesticide analysis, a critical challenge for researchers and food safety professionals. It explores the foundational principles of sensitivity and selectivity, details advanced methodological workflows like modified QuEChERS and automated SPE coupled with GC-MS/MS and LC-MS/MS, and addresses major troubleshooting hurdles such as matrix effects. The content further covers rigorous validation protocols and comparative assessments of emerging techniques, including spectral fusion and non-targeted screening. By synthesizing recent scientific advances, this review serves as a strategic guide for developing robust, sensitive, and reliable analytical methods to meet stringent regulatory standards and ensure public health protection.

The Fundamentals of Trace Analysis: Defining Sensitivity, Selectivity, and Detection Limits

This technical support guide addresses common questions and challenges researchers face when determining the Limits of Detection (LOD), Quantification (LOQ), and linearity in ultra-trace analysis of pesticides.

Fundamental Concepts and Definitions

What are LOD and LOQ, and how do they differ?

The Limit of Detection (LOD) is the lowest concentration of an analyte that can be reliably distinguished from a blank sample but not necessarily quantified as an exact value. The Limit of Quantification (LOQ), a higher concentration, is the lowest level that can be measured with acceptable precision and accuracy for quantitative analysis [1] [2].

- LOD focuses on detection feasibility. It is the concentration where you can be confident the analyte is present, even if you cannot precisely say how much [1].

- LOQ focuses on quantitative reliability. At or above the LOQ, the measurement meets predefined goals for bias (trueness) and imprecision (precision) [1].

What are the standard methods for calculating LOD and LOQ?

There are several accepted approaches, and the choice often depends on the analytical technique and regulatory guidelines.

| Method | Description | Typical Use |

|---|---|---|

| Signal-to-Noise (S/N) | Compares the analyte signal to the background noise. | Chromatographic methods (HPLC, GC) [2]. |

| Standard Deviation of the Blank | Uses the mean and standard deviation of a blank sample's response. | General instrumental methods [1] [3]. |

| Standard Deviation of the Calibration Curve | Uses the residual standard deviation (or standard error) of the regression line and its slope. | Common in validated method protocols [2] [3]. |

| Empirical / Visual Evaluation | Determining the minimum level at which the analyte can be observed or quantified. | Non-instrumental methods (e.g., microbial inhibition) [2]. |

The most common formulas based on standard deviation and the calibration curve slope (S) are:

Here, 'σ' represents the standard deviation, which can be derived from the blank or the calibration curve, and 'S' is the slope of the calibration curve [3].

What is meant by a linear calibration curve, and how is it measured?

A linear calibration curve demonstrates a directly proportional relationship between the analyte's concentration and the instrument's response. It is fundamental for accurate quantification.

Linearity is typically measured by the coefficient of determination, R² [4] [5]. An R² value ≥ 0.99 is often considered acceptable for quantitative trace analysis, with values closer to 1.000 indicating a stronger linear relationship [4]. The curve should be built with an appropriate number of calibration levels across the expected concentration range [3].

Experimental Protocols and Performance Data

The following table summarizes LOD and LOQ performance from recent pesticide analysis studies, demonstrating achievable sensitivity with modern techniques.

Table 1: Experimental LOD and LOQ Values from Recent Pesticide Research

| Analysis Target; Matrix | Analytical Technique | Sample Preparation | Reported LOD Range | Reported LOQ Range | Linearity (R²) | Citation |

|---|---|---|---|---|---|---|

| Carbamate pesticides; Camel Milk | UHPLC-MS/MS | Liquid-Liquid Extraction (LLE) | 0.0072 – 0.0578 µg/kg | 0.0217 – 0.1753 µg/kg | ≥ 0.997 | [4] |

| 61 Pesticides; Vegetables (Tomato, Eggplant, Okra) | GC-MS/MS & UHPLC-q-TOF/MS | QuEChERS | 0.0004 – 0.0065 mg/kg | 0.0014 – 0.021 mg/kg | > 0.99 | [5] |

| 67 Pesticides; Water | GC-MS/MS | Automated Solid-Phase Extraction (SPE) | - | 0.010 – 0.080 µg/L | - | [6] |

Detailed Experimental Workflow

The methodology for determining LOD, LOQ, and linearity follows a systematic workflow, from preparation to calculation.

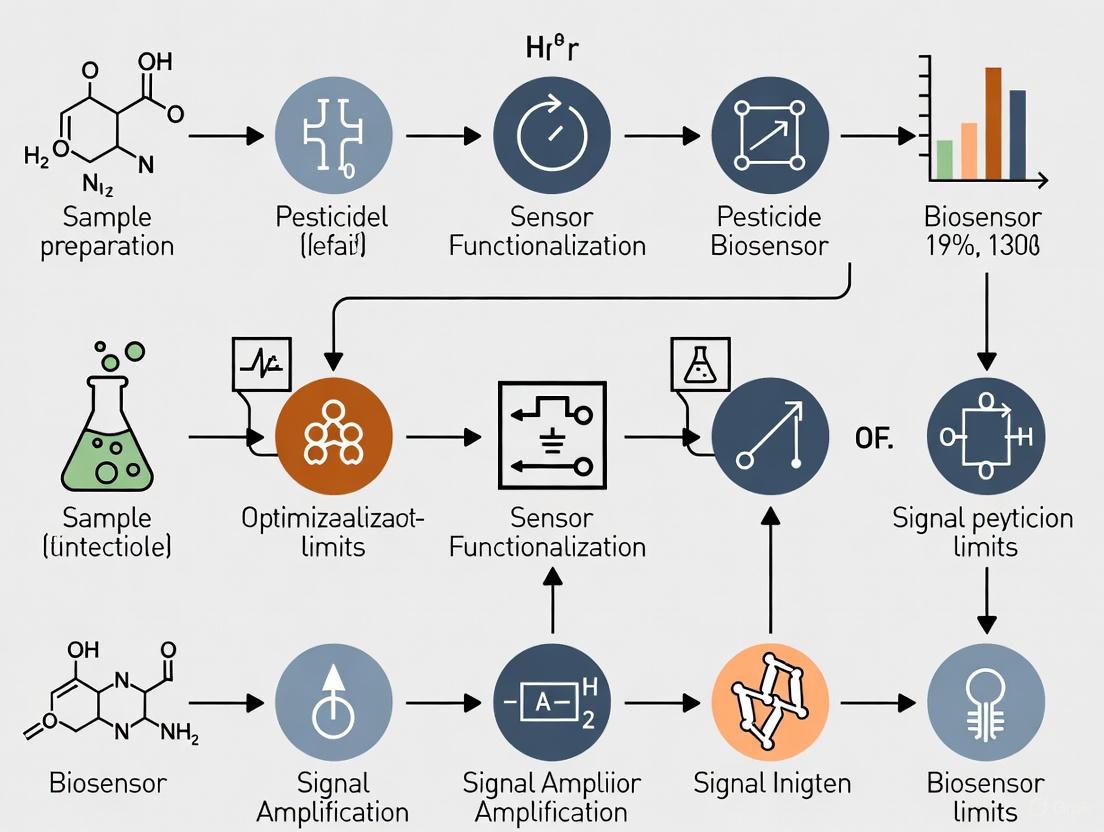

Workflow for Determining LOD, LOQ, and Linearity

Troubleshooting Common Experimental Issues

Our calculated LOD/LOQ values are higher than expected. What could be the cause?

High LOD/LOQ values are typically caused by excessive background noise or signal variability. Key areas to investigate:

- Contamination: This is a primary suspect in ultra-trace analysis. Ensure high-purity reagents, use laminar flow boxes during preparation, and properly condition labware [7].

- Sample Matrix Effects: Complex sample matrices can suppress or enhance the analyte signal. Use matrix-matched calibration standards or isotope-labeled internal standards to compensate [5] [6].

- Instrument Performance: Suboptimal instrument tuning and maintenance can reduce sensitivity and increase noise. Regularly optimize the plasma (for ICP-MS), ion optics, and source parameters [7].

- Sample Preparation Inefficiency: Inefficient extraction or clean-up can lead to poor analyte recovery. Optimize your extraction method (e.g., QuEChERS, SPE) for your specific analyte-matrix combination [5] [8].

How can we improve the linearity of our calibration curve?

Poor linearity, indicated by a low R² value, can be addressed by:

- Checking for Contamination in Low-Level Standards: Ensure your blank and lowest calibration standards are not contaminated.

- Verifying Standard Preparation: Accurately prepare calibration standards and use appropriate serial dilution techniques.

- Ensuring Instrument Linearity: Analyze the calibration curve for outliers and confirm the instrument's detector is not saturated at the high end of the concentration range.

- Using a Weighted Regression Model: For wide calibration ranges where variance is not constant across concentrations, a weighted linear regression model (e.g., 1/x or 1/x²) can significantly improve accuracy at the lower end [3].

How does the sample matrix influence LOD and LOQ?

The sample matrix can profoundly impact LOD and LOQ by contributing to the background signal (noise) and interfering with the analyte's detection [3]. A "complex analytical system" makes it difficult to obtain a true, analyte-free blank, which is critical for accurate LOD/LOQ calculation [3].

- Strategy: Always use a blank that is commutable with your real samples (i.e., has the same matrix) to account for this background [1] [3]. For example, in the camel milk study, the method was validated using the same milk matrix to ensure accuracy [4].

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Ultra-Trace Pesticide Analysis

| Item | Function in Analysis | Example / Note |

|---|---|---|

| Ultra-Pure Reagents & Acids | Used for sample preparation and standard dilution to minimize background contamination. | Essential for achieving pg/L level detection in ICP-MS [7]. |

| QuEChERS Extraction Kits | Quick, Easy, Cheap, Effective, Rugged, and Safe multi-residue extraction for food matrices. | Used for pesticide screening in vegetables [5]. |

| SPE (Solid-Phase Extraction) Cartridges | Extract and concentrate analytes from liquid samples like water; reduce matrix interference. | WAX cartridges were optimized for 75 PFAS in drinking water [8]. |

| Analyte Protectants | Compounds added to sample extracts to deactive active sites in GC systems, improving peak shape & sensitivity. | Gluconolactone and D-sorbitol enhanced GC-MS/MS sensitivity for pesticides [6]. |

| Certified Reference Materials | Validate method accuracy and precision by analyzing a material with a known analyte concentration. | Crucial for verifying method performance in geochemical analysis [9]. |

| Matrix-Matched Calibration Standards | Calibration standards prepared in a blank matrix to compensate for matrix-induced signal suppression/enhancement. | Vital for accurate quantification in complex samples like milk and vegetables [4] [5]. |

Frequently Asked Questions (FAQs)

Can the LOQ be the same as the LOD?

The LOQ can be equivalent to the LOD only if the predefined goals for bias and imprecision are met at the LOD concentration. In practice, the LOQ is almost always at a higher concentration than the LOD [1].

Why do different guidelines suggest slightly different ways to calculate LOD/LOQ?

Different organizations (IUPAC, ICH, CLSI, EPA) have developed protocols based on their specific needs and historical practices. While the underlying principles are similar, the exact formulas (e.g., using 3.3σ/S vs. other factors) and required experimental designs (e.g., number of replicates) can vary [3]. It is critical to state which guideline or calculation method you are following to ensure your results are interpretable and comparable [3].

Is a high signal-to-noise (S/N) ratio the only factor for a good LOD?

No. While a high S/N is crucial, it is not the only factor. The slope of the calibration curve (sensitivity) is equally important. A steeper slope means a larger change in signal for a given change in concentration, which directly leads to a lower LOD, as seen in the LOD calculation formula LOD = 3.3 * σ / S [2] [3].

Frequently Asked Questions (FAQs)

Q1: What are the most common causes of matrix effects in GC-MS/MS analysis of pesticides, and how can I mitigate them? Matrix effects occur when co-extracted compounds from your sample alter the analytical signal, leading to suppression or enhancement. This is common in complex samples like chili powder due to its high pigment and capsaicin content. To mitigate this, use a modified QuEChERS method with appropriate dispersive Solid-Phase Extraction (d-SPE) clean-up steps. Incorporating analyte protectants (e.g., gluconolactone and D-sorbitol) into your sample and standards can also deactive active sites in the GC system, improve peak shape, and enhance sensitivity. For quantitative accuracy, using matrix-matched calibration standards is highly recommended [5] [6].

Q2: My method recovery rates are low for certain pesticides in a fatty matrix. How can I improve them? Low recovery often stems from inefficient extraction or pesticide degradation during the process. Ensure your extraction solvent is optimized for the target analytes; acetonitrile is common, but you may need adjustments. For fatty matrices like camel milk, an additional clean-up step using freezing or specific d-SPE sorbents (e.g., C18 or Z-Sep) is crucial to remove lipids. Furthermore, validate your method with a systematic recovery test, aiming for results within 70-120% as per SANTE guidelines. Using internal standards can help correct for recovery losses [5] [10].

Q3: How can I lower the detection limits for trace-level pesticide analysis? Enhancing sensitivity requires a multi-pronged approach. First, employ analyte protectants to improve signal response in GC-MS/MS. Second, use advanced instrumentation like GC-MS/MS or LC-MS/MS in MRM mode for superior selectivity and lower baseline noise. Third, concentrate your sample extract during the evaporation/reconstitution step. Finally, ensure your sample preparation effectively removes matrix interferences, which is key to achieving a low signal-to-noise ratio. Methods have been validated with Limits of Quantification (LOQs) as low as 0.0014 mg/kg in vegetables and 0.010 μg L⁻¹ in water [5] [6].

Q4: My chromatographic peaks are broad or tailing. What is the likely cause and solution? Broad or tailing peaks often indicate active sites in the chromatographic system or matrix interference. Check for contamination in your liner or column. If the issue is system-wide, using analyte protectants can help deactivate these sites. If the issue is specific to a complex matrix, improving the sample clean-up protocol is necessary. Also, verify that your injection technique is correct and that your GC method parameters (e.g., inlet temperature, carrier gas flow) are properly optimized [6] [11].

Troubleshooting Guides

Guide 1: Diagnosing and Resolving High Matrix Effects

Problem: Signal suppression or enhancement in the detector due to sample matrix, causing inaccurate quantification.

Symptoms:

- Calibration curves from solvent standards do not match those from matrix-matched standards.

- Recovery rates for spikes into sample matrix are abnormally high or low.

- Inconsistent results between different sample batches.

Solutions:

- Improve Sample Clean-up: Re-evaluate your d-SPE sorbent combination. For challenging matrices, consider a combination of PSA (for polar interferences), C18 (for lipids), and GCB (for pigments) [5].

- Use Analyte Protectants: Add compounds like gluconolactone and D-sorbitol to all standards and samples. This masks active sites in the GC system, leading to sharper peaks and reduced matrix influence [6].

- Switch to Matrix-Matched Calibration: Prepare your calibration standards in a blank matrix extract that is representative of your samples. This is considered a gold-standard approach for compensating for matrix effects [5] [6].

- Employ Internal Standards: Use isotope-labeled internal standards for each analyte. They correct for both matrix effects and recovery losses during sample preparation [10].

Guide 2: Addressing Poor Method Recovery Rates

Problem: The amount of pesticide recovered from a spiked sample is unacceptably low (<70%) or high (>120%).

Symptoms:

- Consistently low or high calculated concentrations for quality control samples.

- Failure during method validation.

Solutions:

- Optimize Extraction: Ensure efficient partitioning during the QuEChERS step. Shake/vortex vigorously and confirm the salting-out step is effective. The recovery should range from 72-124% for a robust method [5].

- Check pH: The acidity of the sample can affect the stability of certain pesticides. Adjust the pH of the sample during extraction to ensure target analytes are in their neutral form for optimal extraction [10].

- Review Clean-up: An overly aggressive clean-up can adsorb analytes. If recovery is low, try using fewer or different sorbents. If recovery is high, increase clean-up rigor to remove more matrix [5].

- Verify Instrument Performance: Ensure the instrument is properly calibrated and that there is no degradation of analytes in the inlet or column.

Experimental Data and Protocols

Table 1: Performance Data of Pesticide Analysis in Different Matrices

| Matrix | Analysis Technique | Number of Pesticides | Recovery Range (%) | Limit of Quantification (LOQ) Range | Key Challenge Noted |

|---|---|---|---|---|---|

| Tomato, Eggplant, Okra [5] | GC-MS/MS (MRM), UHPLC-q-TOF/MS | 61 | 72 - 124 | 0.0014 - 0.021 mg/kg | Matrix effects of ±20%; multiple residues in 25% of market samples. |

| Water [6] | Automated SPE-GC-MS/MS | 67 | 81 - 120 | 0.010 - 0.080 μg L⁻¹ | Thermal degradation & adsorption; overcome with analyte protectants. |

Table 2: Essential Research Reagent Solutions

| Reagent/Material | Function/Purpose | Example Application |

|---|---|---|

| QuEChERS Extraction Kits | Quick, Easy, Cheap, Effective, Rugged, Safe extraction salts and kits for multi-residue analysis. | Primary extraction of pesticides from various food matrices [5]. |

| d-SPE Clean-up Sorbents | Dispersive Solid-Phase Extraction tubes for post-extraction clean-up to remove matrix interferences. | PSA removes fatty acids and sugars; C18 removes lipids; GCB removes pigments [5] [10]. |

| Analyte Protectants | Compounds that mask active sites in the GC system, improving peak shape and sensitivity. | Gluconolactone and D-sorbitol used to mitigate matrix effects in water and plant analysis [6]. |

| Matrix-Matched Standards | Calibration standards prepared in a blank, pre-checked matrix extract. | Compensates for matrix-induced signal suppression/enhancement, crucial for accurate quantification [5] [6]. |

Protocol 1: Modified QuEChERS Method for Complex Matrices

This protocol is adapted from methods used for the analysis of pesticides in vegetables [5].

- Homogenization: Weigh 10.0 ± 0.1 g of the homogenized sample (e.g., chili powder, camel milk) into a 50 mL centrifuge tube.

- Extraction: Add 10 mL of acetonitrile (1% acetic acid) to the tube. Vortex vigorously for 1 minute.

- Partitioning: Add a pre-packaged salt mixture (e.g., 4g MgSO₄, 1g NaCl, 1g Na₃Citrate, 0.5g Na₂HCitrate). Shake immediately and vigorously for 1 minute to prevent clumping.

- Centrifugation: Centrifuge at >4000 rpm for 5 minutes.

- Clean-up: Transfer an aliquot (e.g., 1 mL) of the upper acetonitrile layer to a d-SPE tube containing sorbents (e.g., 150 mg MgSO₄, 25 mg PSA, and 25 mg C18 for fatty matrices; add GCB for pigmented matrices). Vortex for 30 seconds.

- Centrifugation: Centrifuge the d-SPE tube and filter the supernatant through a 0.22 μm syringe filter before instrumental analysis.

Workflow and Troubleshooting Visualizations

Theoretical Foundations: Understanding Signal and Noise

What are the fundamental components of an analytical signal?

All analytical data sets contain two components: signal and noise. The signal is the part of the data that contains information about the chemical species of interest (analyte) and is often proportional to the analyte mass or concentration. In contrast, noise represents extraneous information originating from various sources in the analytical measurement system, including detectors, photon sources, and environmental factors [12].

The relationship between signal and noise is quantified by the signal-to-noise ratio (S/N), which serves as a fundamental metric for evaluating analytical method performance. For an ideal Gaussian peak, S/N equations can be used to derive the chromatographic limit of detection (LOD), though chromatographic systems typically exhibit poorer detection limits compared to static systems due to peak broadening effects [13].

How does the signal-to-noise ratio relate to key performance metrics in pesticide analysis?

In practical pesticide detection applications, S/N forms the theoretical foundation for several critical performance metrics. The limit of detection (LOD) is typically defined as a S/N ratio of 3:1, while the limit of quantification (LOQ) corresponds to a S/N ratio of 10:1 [14]. These relationships establish the fundamental connection between signal quality and method sensitivity.

Other performance metrics directly influenced by S/N characteristics include:

- Prediction correlation coefficient (R²P): Measures prediction accuracy of models

- Root mean square error of prediction (RMSEP): Evaluates predictive accuracy on independent test sets

- Ratio of performance to deviation (RPD): Reflects predictive capability relative to data variability [15]

Table 1: Key Performance Metrics in Pesticide Analysis and Their Relationships to Signal and Noise

| Metric | Definition | Theoretical Relationship to S/N | Optimal Range |

|---|---|---|---|

| LOD | Lowest detectable concentration | S/N ≥ 3:1 | Method-dependent |

| LOQ | Lowest quantifiable concentration | S/N ≥ 10:1 | Method-dependent |

| R²P | Prediction correlation coefficient | Improves with higher S/N | >0.99 for excellent models [15] |

| RMSEP | Root mean square error of prediction | Decreases with higher S/N | Lower values preferred [15] |

| RPD | Ratio of performance to deviation | Enhances with better S/N | >2.0 for acceptable models [15] |

Troubleshooting Common Signal and Noise Issues

Why does my chromatographic method exhibit higher detection limits than expected?

Chromatographic detection limits are often poorer than theoretical predictions due to peak broadening effects during separation. This phenomenon occurs because the analyte band spreads as it travels through the chromatographic system, effectively diluting the signal and reducing S/N ratios. A possible determinate error in area measurement can result when integration limits are chosen based on the static detection limit rather than accounting for these chromatographic band-broadening effects [13].

Solution: Optimize chromatographic parameters to minimize peak broadening:

- Use smaller particle size columns for improved efficiency

- Optimize mobile phase composition and flow rate

- Maintain proper column temperature control

- Ensure appropriate injection volume relative to column dimensions

How can I address matrix effects that degrade S/N in complex samples?

Matrix effects represent a significant challenge in pesticide residue analysis, particularly in complex food matrices like edible insects, which contain high levels of fat and protein that can interfere with analysis [16]. These matrix components co-extract with target analytes, potentially causing ion suppression/enhancement in mass spectrometry or spectral interference in spectroscopic methods.

Solution: Implement effective sample cleanup strategies:

- QuEChERS with optimized solvent/sample ratios: Increasing acetonitrile volume from 5mL to 15mL improved pesticide recovery from 21 to 45 compounds in edible insect samples [16]

- dSPE cleanup with selective sorbents: PSA effectively removes fatty acids and sugars; C18 eliminates non-polar interferences; GCB removes pigments [16]

- Freeze-drying preparation: Reduces water content without applying heat, minimizing analyte degradation [16]

Table 2: Troubleshooting Guide for Common Signal and Noise Problems

| Problem | Possible Causes | Diagnostic Tests | Solutions |

|---|---|---|---|

| High baseline noise | Contaminated mobile phase, detector lamp failure, electronic interference | Blank injection, wavelength scan | Filter mobile phases, replace UV lamp, use grounded outlets |

| Poor LOD/LOQ | Matrix effects, inadequate detector response, peak broadening | Standard injection in solvent vs matrix, peak symmetry analysis | Enhance sample cleanup, optimize detection parameters, improve separation |

| Signal drift | Temperature fluctuations, mobile phase degradation, column aging | System suitability tests over time | Use column heater, prepare fresh mobile phases, replace aged column |

| Irreproducible signals | Injection variability, sample degradation, autosampler issues | Repeated injections of same sample | Check injection volume, ensure sample stability, service autosampler |

| Matrix effects >20% | Co-extracted compounds, inadequate sample cleanup | Post-column infusion, post-extraction spike | Optimize QuEChERS ratio (3:1 solvent:sample), add cleanup sorbents [16] |

Advanced Techniques for Signal Enhancement and Noise Reduction

How can spectral techniques combined with machine learning improve S/N characteristics?

The combination of spectroscopic techniques with machine learning algorithms provides powerful approaches for enhancing effective S/N ratios through computational means. Near-infrared spectroscopy (NIRS) and surface-enhanced Raman spectroscopy (SERS) can be integrated with machine learning to denoise original spectra, eliminate matrix interference, and extract feature variables related to pesticide residues [15].

Experimental Protocol: NIRS and SERS Feature-Layer Fusion

- Spectral Acquisition: Collect NIR (700-2500 nm) and SERS spectra of samples

- Feature Selection: Apply Hilbert-Schmidt Independence Criterion-based Variable Space Iterative Optimization (HSIC-VSIO) for feature variable selection

- Data Fusion: Combine selected features from both spectral techniques

- Model Building: Develop Partial Least Squares Regression (PLSR) model with fused features

- Validation: Evaluate using RMSE, R², and RPD metrics [17]

This approach demonstrates significant superiority over single spectral techniques, with a reported prediction set R² of 0.988 and RPD of 8.290 for pesticide residue detection in complex matrix samples [17].

What computational approaches can extract signals from noisy data?

Deep learning algorithms offer advanced capabilities for automated feature extraction and noise reduction. Modifications to standard architectures can significantly enhance performance:

- 1D-CNN with multi-scale convolutional kernels: Using kernels of sizes 3, 5, and 7 with feature fusion structures achieved 95.83% accuracy in pesticide classification on Hami melon surfaces, outperforming PLS-DA (88.33%) and SVM (85.83%) [15]

- Attention mechanism modules: Added to 1D-CNNs to enhance model efficiency and computational performance [15]

- Generative Adversarial Networks (GANs): Used with terahertz spectroscopy to achieve 91.4% accuracy in pesticide detection [15]

Experimental Design and Method Optimization

What are the critical factors in QuEChERS method optimization for improved S/N?

Optimizing the QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) method is crucial for enhancing S/N ratios in pesticide residue analysis. Key parameters that significantly impact extraction efficiency and subsequent signal quality include:

Solvent-to-sample ratio: A 3:1 ratio of acetonitrile to sample (15 mL:5 g) demonstrated optimal recovery for lipophilic pesticides in edible insect matrices, increasing detectable pesticides from 21 to 45 compounds compared to 1:1 ratio [16].

Experimental Protocol: Optimized QuEChERS for Complex Matrices

- Sample Preparation: Homogenize 5 g sample and transfer to 50 mL centrifuge tube

- Extraction: Add 15 mL acetonitrile and 5 mL water, shake vigorously for 5 minutes

- Partitioning: Add extraction package (6 g MgSO₄ + 1.5 g sodium citrate), shake for 1 minute

- Centrifugation: Centrifuge at 4000 rpm for 5 minutes

- Cleanup: Transfer 8 mL supernatant to dSPE tube (PSA, C18, MgSO₄), shake for 1 minute

- Final Centrifugation: Centrifuge at 4000 rpm for 5 minutes

- Analysis: Transfer supernatant to vial for GC-MS/MS or LC-MS/MS analysis [16]

Cleanup sorbent selection: The choice of dSPE sorbents must be matrix-specific:

- PSA: Effective for removing fatty acids and sugars

- C18: Ideal for eliminating non-polar interferences

- GCB: Best for pigment removal but may adsorb planar pesticides [16]

How should I validate method performance for trace pesticide analysis?

Comprehensive validation ensures optimal S/N characteristics translate to reliable analytical performance. The following parameters should be evaluated:

Table 3: Method Validation Parameters and Acceptance Criteria for Pesticide Analysis

| Validation Parameter | Experimental Procedure | Acceptance Criteria | Reference |

|---|---|---|---|

| Linearity | Matrix-matched calibration curves (5-7 points) | R² ≥ 0.99 | [18] |

| LOD/LOQ | Serial dilution to S/N=3 and S/N=10 | LOD: 1-10 μg/kg, LOQ: 10-15 μg/kg | [16] |

| Recovery | Spiking at 3 levels (10, 100, 500 μg/kg) | 70-120% with RSD <20% | [18] [16] |

| Precision | Repeated analysis (n=5) at multiple levels | RSD ≤15% | [18] |

| Matrix Effects | Compare slopes in solvent vs matrix | -20% to +20% (minimal effect) | [16] |

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 4: Essential Research Reagents and Materials for Pesticide Residue Analysis

| Item | Function/Application | Key Considerations |

|---|---|---|

| Acetonitrile | Primary extraction solvent | HPLC/GC-MS grade; optimize volume (15 mL for 5 g sample) [16] |

| MgSO₄ (anhydrous) | Water removal from organic phase | Must be anhydrous; 6 g per sample typical [16] |

| Sodium Citrate | Buffer salt for pH control | Part of QuEChERS salt mixture (1.5 g per sample) [16] |

| PSA Sorbent | Removal of fatty acids, sugars, organic acids | 150 mg per sample typical; may not suffice for all matrices [16] |

| C18 Sorbent | Removal of non-polar interferences | 150 mg per sample; essential for fatty matrices [16] |

| GCB Sorbent | Pigment removal | Use cautiously as it adsorbs planar pesticides [16] |

| Gold Nanoparticles (AuNPs) | SERS substrate for signal enhancement | Various morphologies/sizes; plasmonic properties [19] |

| Silver Nanoparticles (AgNPs) | SERS substrate for greater enhancement | Higher enhancement factors than AuNPs but less stable [19] |

| Graphene Oxide | SERS chemical enhancement via π-π interactions | Improves adsorption of aromatic pesticide molecules [19] |

Frequently Asked Questions

What is the difference between instrumental LOD/LOQ and method LOD/LOQ?

Instrumental LOD/LOQ refers to the detection and quantification limits measured using pure standards in solvent, representing the fundamental capability of your analytical instrument. Method LOD/LOQ incorporates the entire analytical process including sample preparation, matrix effects, and extraction efficiency, providing a more realistic assessment of method performance with real samples. Method LOD/LOQ values are typically 3-5 times higher than instrumental values due to matrix effects and sample preparation losses [14] [16].

How can I determine whether my method is limited by instrumental sensitivity or sample preparation?

Perform a post-extraction spike experiment to differentiate between limitations:

- Prepare matrix-matched standards by spiking pesticides into final extract

- Compare response with solvent-based standards at same concentrations

- If response is similar, limitation is instrumental sensitivity

- If response is significantly lower in matrix, limitation is sample preparation efficiency

This approach helps direct optimization efforts to the appropriate area of your analytical workflow [16].

What strategies are most effective for detecting ultratrace pesticides (<1 μg/kg)?

For ultratrace analysis, consider these advanced approaches:

- SERS with engineered nanomaterials: Surface-enhanced Raman spectroscopy using gold/silver nanoparticles of various morphologies can enhance signals by 10⁴-10¹⁰ fold through plasmonic effects [19]

- LC-QTOF/MS: Provides enhanced resolution, accuracy, and sensitivity for both non-targeted and targeted screening [16]

- Large-volume injection GC-MS/MS: Increases absolute amount of analyte reaching detector

- Additional preconcentration steps: Evaporate and reconstitute in smaller volume (2-5× concentration factor) [14]

Regulatory Frameworks and Maximum Residue Limits (MRLs) as Performance Benchmarks

Maximum Residue Limits (MRLs), also referred to as pesticide tolerances in some countries, are the highest legally permissible levels of pesticide residues allowed in or on food commodities and feed [20]. Regulatory bodies, such as the U.S. Environmental Protection Agency (EPA) and the European Medicines Agency (EMA), establish these limits to ensure food safety and protect consumer health [20] [21]. For researchers, MRLs serve as critical performance benchmarks when developing and validating analytical methods for trace pesticide analysis. The method's sensitivity, typically defined by its Limit of Quantitation (LOQ), must be sufficient to reliably detect and measure residues at or below the established MRL for the target analyte and commodity [22].

Frequently Asked Questions (FAQs)

Q1: How do MRLs influence the method validation parameters in trace pesticide analysis? MRLs directly dictate the required sensitivity of an analytical method. Your method's Limit of Quantitation (LOQ) must be at or below the MRL for each pesticide-commodity pair to ensure compliance monitoring. Furthermore, method validation parameters—including accuracy (recovery), precision (relative standard deviation), and specificity—must be established and meet accepted guidelines like the SANTE/11312/2021 to demonstrate the method's reliability at these low concentrations [16] [5].

Q2: What are the key differences in MRL regulations between major markets like the U.S. and the E.U.? MRLs are not globally harmonized and can vary significantly. The U.S. EPA sets and enforces tolerances [20], while in the European Union, the European Commission establishes legally binding MRLs based on assessments by the EMA and the European Food Safety Authority (EFSA) [21]. The E.U. standards are often more numerous and stringent for certain substances, and a default MRL of 10 ppb may be applied where a specific limit is not established [22]. Researchers must target the MRLs of their intended market.

Q3: Where can I find reliable and up-to-date MRL information for my research? Official government databases are the primary source. In the U.S., the USDA Pesticide MRL Database is a key resource [22]. For the E.U., information is published in the annex to Commission Regulation (EU) No 37/2010 [21]. Commercial databases, such as FoodChain ID's Regulatory Limits, aggregate global MRL data from nearly 1,000 government sources and are updated daily, which can streamline the research process [23].

Q4: My research involves a complex matrix (e.g., edible insects). How do matrix effects impact method feasibility relative to MRLs? Complex matrices with high fat or protein content, such as edible insects, present significant analytical challenges. These matrices can cause strong ion suppression or enhancement in mass spectrometric detection, compromising accuracy and sensitivity [16]. The feasibility of achieving the required LOQ for an MRL is heavily dependent on effectively mitigating these matrix effects through optimized sample preparation, such as a modified QuEChERS cleanup, and the use of matrix-matched calibration [16] [24].

Troubleshooting Guides

Poor Recovery Rates During Method Validation

Problem: Recovery rates for target pesticides fall outside the acceptable range (typically 70-120%) during method validation [16] [5].

| Possible Cause | Solution |

|---|---|

| Incomplete Extraction | Increase solvent volume or sample-to-solvent ratio. For lipophilic pesticides in complex matrices, a higher acetonitrile volume improves partitioning from the matrix [16]. |

| Analyte Degradation | Check stability of standard solutions. Reduce extraction time or temperature. Use amber glassware to prevent photodegradation. |

| Inefficient Cleanup | Re-evaluate dSPE sorbents. For fatty matrices, increase the amount of PSA or C18 to better remove co-extracted lipids and fatty acids [16] [24]. |

High Matrix Effects Leading to Inaccurate Quantification

Problem: Signal suppression or enhancement (>±20%) is observed, making accurate quantification difficult [16] [5].

| Possible Cause | Solution |

|---|---|

| Insufficient Sample Cleanup | Incorporate additional cleanup sorbents like graphitized carbon black (GCB) for pigment removal or C18 for lipid removal [16] [24]. |

| Inappropriate Calibration | Switch from solvent-based calibration to matrix-matched calibration. This involves preparing calibration standards in a blank matrix extract to compensate for matrix effects [24]. |

| High Matrix Concentration | Dilute the final sample extract before injection, provided the method's LOQ is not compromised. This reduces the absolute amount of matrix entering the instrument [24]. |

Failure to Achieve Required LOQ for a Specific MRL

Problem: The method's Limit of Quantitation is not low enough to monitor compliance with a stringent MRL.

| Possible Cause | Solution |

|---|---|

| Low Instrument Sensitivity | Optimize MS/MS parameters (e.g., collision energy, fragmentor voltage) for the target analytes. Use a large volume injection technique in GC or LC to introduce more analyte [24]. |

| High Background Noise | Ensure the GC-MS/MS or LC-MS/MS system is clean and well-maintained. Use a longer chromatographic gradient to separate analytes from co-eluting matrix interferences [24]. |

| Suboptimal Sample Prep | Concentrate the final extract by evaporating and reconstituting in a smaller volume of solvent, thereby increasing the analyte concentration [16]. |

Experimental Protocols & Data Presentation

Optimized QuEChERS Protocol for Complex Matrices

This protocol, adapted from research on edible insects and vegetables, is designed to handle challenging, high-fat matrices while achieving the low detection limits required for MRL compliance [16] [5].

- Homogenization: Pre-freeze the sample with liquid nitrogen and grind to a fine powder. This ensures a homogeneous representative sample.

- Freeze-Drying: Lyophilize the sample to remove water. This prevents dilution during extraction and allows for better control over solvent-to-sample ratios without risking thermal degradation of analytes [16].

- Extraction: Weigh 2.5 g of the freeze-dried sample into a 50 mL centrifuge tube. Add 15 mL of acetonitrile and 5 mL of water. Agitate vigorously for 5 minutes. A higher solvent-to-sample ratio is critical for efficient extraction of lipophilic pesticides from fatty matrices [16].

- Partitioning: Add a salt mixture (e.g., 6 g MgSO₄ and 1.5 g sodium citrate) to induce phase separation. Shake immediately and centrifugate.

- dSPE Cleanup: Transfer an aliquot (e.g., 1 mL) of the upper acetonitrile layer to a dSPE tube containing a combination of sorbents (e.g., 150 mg MgSO₄, 25 mg PSA, and 25 mg C18). Vortex and centrifugate. The C18 sorbent is particularly important for removing non-polar interferents like lipids [16].

- Analysis: Transfer the purified extract to a vial for analysis by GC-MS/MS or LC-MS/MS.

Method Validation Data from Recent Studies

The following table summarizes key validation parameters from recent studies, demonstrating the performance required for MRL-based analysis.

Table 1: Method Validation Parameters for Pesticide Residue Analysis

| Parameter | Reported Performance | Acceptable Criteria (e.g., SANTE Guideline) | Reference |

|---|---|---|---|

| Linearity | R² = 0.9940 - 0.9999 | Typically >0.99 | [16] |

| Recovery (%) | 72% - 124% (vegetables); 64.54% - 122.12% (edible insects) | 70 - 120% (with RSD < 20%) | [16] [5] |

| Limit of Detection (LOD) | 0.0004 - 0.0065 mg/kg (vegetables); 1 - 10 µg/kg (edible insects) | Compound-specific, must be sufficiently lower than the MRL | [16] [5] |

| Limit of Quantitation (LOQ) | 0.0014 - 0.021 mg/kg (vegetables); 10 - 15 µg/kg (edible insects) | At or below the MRL | [16] [5] |

| Matrix Effect (%ME) | -33.01% to +24.04% (edible insects) | Ideally within ±20% | [16] |

Visualization of Workflows and Relationships

MRL-Driven Analytical Method Development

This diagram illustrates the logical workflow for developing an analytical method where MRLs are the primary performance benchmark.

QuEChERS Sample Preparation Workflow

This diagram details the optimized QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) sample preparation workflow, a standard in multi-residue pesticide analysis.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table 2: Key Reagents and Materials for Pesticide Residue Analysis

| Item | Function | Application Note |

|---|---|---|

| Acetonitrile (ACN) | Primary extraction solvent for QuEChERS. | High purity grade is essential to reduce background interference. Volume may be increased for fatty matrices [16]. |

| QuEChERS Salt Kits (MgSO₄, NaCl, Citrate buffers) | Induces liquid-liquid partitioning, separating organic phase from aqueous sample. | MgSO₄ removes residual water; citrate buffers help control pH and improve recovery of pH-sensitive compounds [16] [24]. |

| dSPE Sorbents (PSA, C18, GCB, MgSO₄) | Dispersive Solid-Phase Extraction for sample cleanup. | PSA removes fatty acids and sugars; C18 removes lipids; GCB removes pigments and sterols. The choice depends on the matrix [16] [24]. |

| Analytical Standards | Certified reference materials for target pesticides. | Used for instrument calibration, recovery studies, and determining LOD/LOQ. Must be traceable to a primary standard. |

| Internal Standards (e.g., Isotope-labeled) | Compensates for analyte loss during preparation and matrix effects during analysis. | Added at the beginning of extraction. Crucial for achieving high accuracy and precision in quantitative analysis [24]. |

| GC-MS/MS or LC-MS/MS System | Determinative technique for separation, identification, and quantification of residues. | GC-MS/MS is ideal for volatile and semi-volatile pesticides; LC-MS/MS is better for polar, thermolabile, or high molecular weight compounds [24] [22]. |

High-Resolution Workflows: From Sample Preparation to Instrumental Analysis

Troubleshooting Guide: Addressing Common Challenges

Problem: Poor Recovery of Polar or Acidic Pesticides

Cause: The primary secondary amine (PSA) sorbent used for clean-up can strongly retain acidic or certain polar analytes, leading to their loss and low recovery [25].

Solution:

- Omit the dSPE clean-up step: Directly analyze the supernatant from the extraction/partitioning step [25].

- Conduct a comparative test: Perform the method with and without the PSA dSPE clean-up to determine if PSA is causing the problem and if its omission is a viable solution for your target analytes [25].

- Optimize pH: For pH-sensitive pesticides, ensure the extraction is buffered to a range (e.g., pH 5–5.5 using EN salts or ~4.75 using AOAC salts) that stabilizes the target compounds [26] [27].

Problem: Excessive Lipid Co-extraction in High-Fat Samples

Cause: Standard QuEChERS methods using only PSA and MgSO₄ are insufficient for effectively removing non-polar interferences like lipids, waxes, and sterols [28].

Solution:

- Use enhanced dSPE sorbents: Incorporate C18-EC sorbent into the clean-up. Its primary action is the removal of non-polar interferences, including long-chain hydrocarbons, lipids, and waxes [28]. A combination of PSA, C18-EC, and MgSO₄ is highly effective for fatty samples [28].

- Freeze-out lipids: After the initial extraction and partitioning, store the acetonitrile extract in a freezer (from 2 hours to overnight). Lipids and waxes will precipitate, allowing you to collect the cleaned supernatant. Validate to ensure your target analytes are not co-precipitated [28].

- Employ cartridge SPE (cSPE): For very high-fat samples, pass the extract through a cartridge packed with PSA or C18 sorbents. The lipids are retained in a simple pass-through technique, eliminating complex elution steps [28].

- Perform solvent partitioning: Add a step involving partitioning with a non-polar solvent like hexane to the initial extraction. Lipids will partition into the hexane layer, which can then be discarded [28].

Problem: Inefficient Extraction from Low-Moisture/High-Protein Samples

Cause: The QuEChERS mechanism relies on water to make analytes accessible to the water-miscible extraction solvent (acetonitrile). Dry, high-protein, or starchy samples lack sufficient inherent moisture [27].

Solution:

- Add water to the sample: This is a critical step. The goal is to achieve approximately a 1:1 ratio of total water to acetonitrile. For very dry samples like brown rice flour, this may mean adding a volume of water equal to the volume of acetonitrile used [27].

- Reduce sample mass: Using a smaller sample mass (e.g., 5 g instead of 10 g) with a proportionally larger volume of added water can improve homogenization, shaking efficiency, and make the supernatant easier to recover cleanly [27].

Table 1: Summary of Common Problems and Recommended Modifications

| Problem | Primary Cause | Recommended Modification | Key Considerations |

|---|---|---|---|

| Poor Recovery of Acidic Pesticides | Retention by PSA sorbent | Omit dSPE step or use buffered salts | Test with/without PSA; stabilize pH for sensitive analytes [25] [27]. |

| Excessive Lipid Co-extraction | Insufficient clean-up for non-polar interferences | dSPE with C18-EC; Freezing; cSPE; Hexane wash | C18-EC is primary for lipids; validate analyte loss in freeze-out [28]. |

| Inefficient Extraction from Dry Matrices | Insufficient water for partitioning | Add water (aim for ~1:1 water:ACN ratio); reduce sample mass | Ensure sample is fully hydrated and homogenized [27]. |

| Matrix Effects & Poor Sensitivity | Co-extracted matrix components | Enhanced clean-up; analyte protectants (for GC) | Use appropriate dSPE sorbents; deactivate active sites in GC system [6]. |

Frequently Asked Questions (FAQs)

FAQ 1: How do I select the right dSPE sorbents for my high-fat sample? Select sorbents based on the primary interferences in your matrix. For high-fat samples, a combination is often best. C18-EC is the primary sorbent for removing non-polar lipids and waxes. PSA complements this by removing fatty acids and some sterols. GCB can also remove sterols but should be used with caution as it strongly retains planar pesticides and pigments [28]. A typical effective combination for high-fat samples is PSA/C18-EC/MgSO₄ [28] [25].

FAQ 2: What is the difference between the AOAC and EN buffered QuEChERS methods, and which should I use? Both are buffered versions of QuEChERS, differing in their buffer salt composition and the sample-to-sorbent ratio in the clean-up step.

- AOAC Method: Uses citrate buffers and typically results in a final extract pH of around 4.75. It may provide higher overall pesticide responses for many sample types [27].

- EN Method: Uses acetate buffers, resulting in a more neutral final extract pH of 5.0–5.5 [27]. The choice should be based on the stability of your target pesticides. If they are prone to degradation in acidic conditions, the EN method may be preferable. A literature review for your specific analytes is recommended [25] [27].

FAQ 3: My sample is both high-fat and high in pigments (e.g., avocado). How should I clean it? For matrices rich in both lipids and pigments, a dSPE sorbent combination containing MgSO₄, PSA, C18-EC, and a small amount of GCB can be considered [25]. However, you must first confirm that your target analytes are not planar molecules (e.g., chlorothalonil, hexachlorobenzene), as GCB will strongly adsorb them. If planar pesticides are not a concern, GCB can be highly effective for removing pigments like chlorophyll [28].

FAQ 4: How can I improve sensitivity and reduce matrix effects in GC-MS/MS analysis? Beyond effective sample clean-up, consider using analyte protectants. These are compounds (e.g., gluconolactone, D-sorbitol) added to the final extract that deactivate active sites in the GC system. This results in sharper peaks, improved sensitivity, and can help compensate for matrix-induced suppression effects for certain pesticide classes [6].

Experimental Protocol: Systematic Optimization for Challenging Matrices

The following workflow provides a logical pathway for developing a modified QuEChERS method. The diagram below outlines the key decision points.

Step-by-Step Procedure for High-Fat Sample Analysis

This protocol is adapted from research and application notes focused on challenging matrices like avocado and animal fat [28] [27].

Sample Homogenization:

- Homogenize the entire sample using a powerful chopping device. For high-fat samples, consider using dry ice to prevent loss of volatile pesticides and to facilitate grinding [26].

- Weigh a representative subsample. For high-fat matrices, a sample mass of 5–10 g is typical.

Hydration (if necessary):

- Assess the moisture content. While high-fat samples like avocado (~70% water) may not need additional water, very dry samples (e.g., grains, processed foods) require it. A starting point is to add enough water to achieve a total of 10–15 mL of water in the system [27]. For a 5 g dry sample, this might mean adding 10 mL of water.

Extraction and Partitioning:

- Add the appropriate volume of acetonitrile (typically 10 mL). Acetonitrile is preferred as it co-extracts less lipid material compared to ethyl acetate [26].

- Add the selected extraction salt packet. For a systematic approach, begin optimization tests with AOAC buffered salts (MgSO₄, NaCl, sodium citrate, disodium hydrogen citrate sesquihydrate) as they often provide higher overall pesticide responses [27].

- Shake vigorously for 1 minute to ensure thorough solvent interaction and partitioning.

- Centrifuge to separate the phases.

Clean-up via Dispersive-SPE:

- Transfer an aliquot (e.g., 1 mL) of the upper acetonitrile layer to a dSPE tube. For high-fat samples, use a tube containing PSA, C18-EC, and MgSO₄ [28].

- Shake or vortex for 30–60 seconds to disperse the sorbents.

- Centrifuge to pellet the sorbents and clarified matrix interferences.

- The supernatant is now ready for analysis. Alternatively, for extremely high fat content, employ a freeze-out step at this point or use a cartridge SPE pass-through clean-up [28].

Research Reagent Solutions: Essential Materials

Table 2: Key Reagents and Sorbents for QuEChERS Optimization

| Item | Function | Application Note |

|---|---|---|

| Acetonitrile | Primary extraction solvent | Extracts a broad range of pesticides while co-extracting less lipid material than ethyl acetate [26]. |

| MgSO₄ (Anhydrous) | Drying salt | Added in excess to bind water, reduce the aqueous phase, and improve partitioning of pesticides into the organic layer via the "salting-out" effect [26] [25]. |

| PSA (Primary Secondary Amine) | Sorbent for matrix clean-up | Removes polar interferences: sugars, fatty acids, organic acids, and some pigments. Can undesirably retain acidic pesticides [28] [25]. |

| C18-EC (End-capped C18) | Sorbent for lipid removal | Primary choice for removing non-polar interferences: lipids, waxes, and sterols. Essential for clean-up of high-fat matrices [28]. |

| GCB (Graphitized Carbon Black) | Sorbent for pigment removal | Highly effective at removing chlorophyll and other planar pigments. Use with caution as it also strongly retains planar pesticides [28]. |

| AOAC Buffered Salts | Extraction salts | Buffer system (pH ~4.75) to stabilize pH-sensitive pesticides during extraction. May provide higher recovery for many compounds [27]. |

| Analyte Protectants (e.g., Gluconolactone) | GC system deactivators | Added to final extract to deactive active sites in GC inlet/liner, improving peak shape and sensitivity for problematic analytes [6]. |

Technical Support Center: Troubleshooting Guides and FAQs

This technical support center provides troubleshooting guides and frequently asked questions (FAQs) for researchers working with Ultra-High-Performance Liquid Chromatography (UHPLC) and Gas Chromatography (GC). The content is specifically framed within the context of trace pesticide analysis, focusing on maintaining optimal detection limits and data quality.

UHPLC Troubleshooting Guide

Ultra-High-Performance Liquid Chromatography (UHPLC) is widely used in pesticide analysis due to its high resolution and sensitivity, especially when coupled with tandem mass spectrometry (MS/MS) [29] [30] [31]. Below are common issues and their solutions.

Table: Common UHPLC Problems and Solutions for Pesticide Analysis

| Problem | Symptom | Possible Cause | Solution |

|---|---|---|---|

| Retention Time Shifts [32] | Analytes elute earlier or later than expected. | Mobile phase composition changes; Column temperature fluctuations; Column aging. | Prepare fresh, precise mobile phases; Use a column oven; Equilibrate column thoroughly; Replace aged column. |

| Peak Tailing [32] | Peaks show a long tail on the trailing edge. | Column contamination; Active sites on stationary phase. | Flush column with cleaning solvents; Use end-capped columns. |

| High Back Pressure [32] | System pressure rises above normal. | Clogged frits/filters; Column contamination. | Reverse-flush column if appropriate; Filter mobile phases (0.2–0.45 μm). |

| Baseline Noise [32] | Detector signal shows random fluctuations. | Aging detector lamp; Mobile phase impurities; Air bubbles. | Replace detector lamp; Filter and degas mobile phases; Purge the system. |

| Ghost Peaks [32] | Unexpected peaks appear in blank injections. | Mobile phase contamination; Carryover from previous injections. | Use high-purity solvents; Clean injector and sample loop. |

GC Troubleshooting Guide

Gas Chromatography (GC) is equally vital for analyzing volatile and semi-volatile pesticide residues [33]. Effective troubleshooting in GC often starts with prevention and routine checks [34].

Table: Common GC Problems and Solutions for Pesticide Analysis

| Problem | Symptom | Possible Cause | Solution |

|---|---|---|---|

| Peak Tailing [35] [36] | Asymmetrical peaks with a long trailing edge. | Active sites in the liner or column; Column contamination. | Replace or re-condition the liner; cut a small section from the column inlet; use a deactivated liner. |

| Split Peaks [35] [36] | A single compound produces multiple peaks. | Non-optimal injection technique; column damage. | Ensure proper injection method; inspect and replace column if damaged. |

| Ghost Peaks [35] | Unexpected peaks appear in the chromatogram. | Septum bleed; contamination in the carrier gas line or inlet. | Replace the septum; perform inlet maintenance; use high-purity gas and traps. |

| Changes in Retention Time [35] [36] | Retention times are inconsistent. | Carrier gas leak or flow issue; oven temperature instability. | Check for leaks and repair; verify gas flow rates; ensure oven temperature calibration. |

| No Sample Peak / Low Response [35] | Loss of sensitivity for analytes. | Detector issues (e.g., flame out in FID); incorrect injection; loss of active analytes. | Ensure detector flame is lit; check syringe for blockages; use a liner with higher surface area. |

Frequently Asked Questions (FAQs)

Q1: What are the key considerations when transferring a chromatography method to a new instrument, especially for regulatory trace analysis? [37]

Method transfer requires careful planning. Key steps include understanding the performance capabilities of the new instrument (e.g., pressure limits, dwell volume, detector cell volume), verifying critical method parameters, and conducting a robustness test. Using information-rich detectors like mass spectrometers can help confirm a successful transfer that preserves analytical quality and accuracy, which is paramount for pesticide monitoring.

Q2: How can I reduce the need for troubleshooting in my GC analysis? [34]

Much of GC troubleshooting is done before injection. This involves proactive maintenance checks of gas supplies, inlets, and detectors, using high-quality consumables, and ensuring proper sample preparation. Adopting robust approaches during method development can prevent common analytical drawbacks.

Q3: My UHPLC peaks are broader than expected, and I'm losing sensitivity for trace pesticides. What could be the issue? [38]

This is often related to instrument band spreading or extracolumn effects. UHPLC instruments are designed with very low-volume flow paths to be compatible with the narrow peaks produced by modern columns. You can measure your system's Instrument Bandwidth (IBW) by replacing the column with a zero-dead-volume union and injecting a small sample. A large IBW indicates that your instrument components (e.g., tubing, detector cell) are too voluminous for your method, causing peak broadening and reduced sensitivity. Ensure all connections use narrow-bore tubing and the system is optimized for UHPLC.

Q4: For multi-residue pesticide analysis in complex food matrices, what is a recommended comprehensive strategy? [33]

A robust strategy involves using multi-residue workflows like QuEChERS for sample preparation, followed by parallel analysis using both LC-MS/MS and GC-MS/MS. This ensures coverage across a wide spectrum of pesticides with different polarities and volatilities. Integrating this analytical data with probabilistic risk assessment models is now a standard practice for dietary exposure and safety evaluations.

Experimental Protocols for Pesticide Analysis

Validated Protocol 1: UHPLC-MS/MS Analysis of Pesticides in Water [31]

This protocol was used to analyze carbaryl, methiocarb, diazinon, chlorpyrifos, and cypermethrin in agricultural water samples.

- Sample Preparation: Water samples were processed using a refined QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) extraction method.

- Instrumentation: Analysis was performed using an UPLC-MS/MS system.

- Chromatography: The method achieved separation of all five pesticides within a short runtime.

- Performance: The method demonstrated high sensitivity, with limits of detection and quantification suitable for monitoring trace-level pesticide residues in environmental water samples.

Validated Protocol 2: UHPLC-MS/MS for Pesticide Mixture in Aquatic Toxicity Testing [30]

This protocol details the analysis of a metolachlor, epoxiconazole, and chlorantraniliprole mixture.

- Extraction: Solid phase extraction (SPE) was used for artificial freshwater samples.

- Instrumentation: Ultra-performance liquid chromatography-tandem quadrupole mass spectrometry.

- Chromatography: Compounds were separated within 1.30 minutes.

- Method Validation:

- Linearity: 2-150 µgL⁻¹ for CAP and 50-3000 µgL⁻¹ for EP and MET.

- Precision and Accuracy: Met intra-assay validation requirements.

- Recovery: Ranged between 77% and 120% at low and high concentration levels.

Workflow Visualization

The following diagram illustrates the integrated workflow for pesticide residue analysis using chromatographic techniques, from sample to result.

The Scientist's Toolkit: Essential Research Reagents & Materials

Table: Key Materials for Chromatographic Pesticide Residue Analysis

| Item | Function in Analysis | Example Application |

|---|---|---|

| QuEChERS Kits [29] [33] | A streamlined sample preparation method for extracting pesticides from various food and environmental matrices. | Extraction of 73 pesticide residues from leafy vegetables (cress, basil, mint) for UHPLC-MS/MS analysis [29]. |

| Solid Phase Extraction (SPE) [30] [31] | Used to clean up and pre-concentrate analytes from liquid samples, improving sensitivity and reducing matrix effects. | Extraction and concentration of metolachlor, epoxiconazole, and chlorantraniliprole from water for aquatic toxicity testing [30]. |

| UHPLC Guard Columns [32] | A short column placed before the main analytical column to trap contaminants and particulates, extending column life. | Protecting the analytical column from contamination during the analysis of complex vegetable extracts, preventing peak tailing [32]. |

| End-capped UHPLC Columns [32] | Analytical columns where residual silanol groups on the silica are chemically treated to reduce unwanted interactions with basic analytes. | Improving peak shape (reducing tailing) for polar or basic pesticide compounds. |

| Deactivated GC Liners [36] | Glass liners for the GC inlet designed to minimize active sites that can adsorb or degrade analytes. | Preventing peak tailing and loss of response for active pesticides like organophosphates during GC analysis [35]. |

Technical Support Center

Troubleshooting Guides & FAQs

This technical support center addresses common challenges encountered during Tandem Mass Spectrometry (MS/MS) experiments, with a specific focus on applications in trace pesticide analysis. The guides below are designed to help you maintain optimal instrument performance and data quality.

FAQ: Addressing Common LC-MS/MS Challenges

1. My chromatograms are empty, showing no peaks. What should I check? Begin by diagnosing the issue from the sample introduction point forward [39]:

- Sample Injection: Confirm the autosampler vial or well was successfully pierced by the needle and that the sample volume is correct [40].

- Spray Stability: Check that the electrospray is stable. Inspect for clogged lines or issues with the mobile phase flow [39].

- Mass Detection: Verify the mass spectrometer is set to detect the correct mass-to-charge (m/z) values for your target analytes [39].

- Data Processing: Ensure your data processing software is correctly configured to display the extracted ion chromatograms (XICs) for the targeted masses [39].

2. How can I distinguish between a sample preparation problem and an instrument failure? Perform a System Suitability Test (SST) by injecting a neat standard solution, bypassing the sample preparation workflow [40]. A normal SST result indicates a problem likely originated during sample preparation. An abnormal SST confirms an issue with the liquid chromatography (LC) or MS/MS system [40]. Common sample preparation mistakes include [40]:

- Incomplete protein precipitation.

- Errors in derivatization.

- Inefficient solid-phase extraction (SPE).

- Using expired or contaminated reagents.

3. I am observing a high background signal and carryover in my blank runs. What is the likely cause? This typically indicates system contamination [40] [39].

- Source Contamination: The MS/MS ion source may be contaminated from matrix buildup and requires cleaning [40] [41].

- Mobile Phase/Solvents: Use only high-quality, LC-MS/MS grade solvents and additives. Low-quality solvents are a common source of high background noise [41].

- Carryover: Check and clean the autosampler injection system, including the needle and wash port [41]. Ensure the autosampler wash solvent is strong enough to clean the system and is replaced regularly [40].

4. My sensitivity has dropped significantly. What are the key areas to investigate? A loss of sensitivity can stem from multiple factors. A systematic approach is best:

- MS/MS Source: Contamination of the source and interface components is a primary culprit. Regular cleaning, and potentially replacing interface parts, is necessary to maintain sensitivity [40] [41].

- LC System: Check for slow leaks, especially at tubing connections, which can be identified by buffer deposits or discolored metal fittings [40]. Degraded chromatography, such as peak broadening, can also reduce signal intensity.

- Mobile Phase: Confirm the quality and composition of the mobile phase. Salt precipitation or microbial growth in aqueous buffers can severely impact sensitivity [41].

- Calibration: Recalibrate the mass spectrometer using a certified calibration solution to ensure mass accuracy and detector response are within specifications [42].

5. How can I improve the detection limits for trace pesticide analysis in complex food matrices? Optimizing the entire workflow is key to enhancing detection limits [43] [44]:

- Sample Cleanup: Implement a robust purification method. A modified QuEChERS approach using adsorbents like hydroxylated multi-walled carbon nanotubes (MWCNTs), strong anion exchange (SAX), and C18 can effectively remove pigments, fatty acids, and other matrix interferents, reducing background noise [43].

- Chromatographic Separation: Optimize the LC method to achieve sharp, well-resolved peaks, which improves the signal-to-noise ratio [41].

- MS/MS Optimization: Carefully optimize the declustering potential (DP) and collision energy (CE) for each pesticide to maximize the signal of the precursor and product ions [43].

Troubleshooting Flowchart: Diagnosing LC-MS/MS Performance Issues

This diagram outlines a logical path to diagnose common instrument problems.

Optimizing Detection Limits in Pesticide Analysis: Experimental Protocols

Protocol 1: Modified QuEChERS Extraction and Purification for Multi-Pesticide Residues

This protocol is adapted from a method developed to analyze 51 pesticide residues in diverse foodstuffs, achieving limits of quantification (LOQ) as low as 0.2 µg/kg [43].

1. Sample Preparation:

- Homogenize representative samples of vegetables, fruits, grains, meat, eggs, or milk.

2. Extraction:

- Weigh 10 ± 0.1 g of homogenized sample into a 50 mL centrifuge tube.

- Add 10 mL of acetonitrile and shake vigorously for 1 minute.

- Add a citrate-buffered salt package (e.g., containing MgSO4 and NaCl) to induce phase separation.

- Shake vigorously for another minute and centrifuge at >4000 rpm for 5 minutes.

3. Purification (Modified QuEChERS):

- Transfer the upper acetonitrile layer (approximately 6 mL) into a 15 mL centrifuge tube containing a combination of purification adsorbents:

- 150 mg hydroxylated Multi-Walled Carbon Nanotubes (MWCNTs) - Effective for removing pigments and planar molecules.

- 150 mg Strong Anion Exchange (SAX) - Removes anionic interferents.

- 150 mg C18 - Removes non-polar interferents like fats.

- Shake the mixture for 1 minute and centrifuge at >4000 rpm for 5 minutes.

- The purified extract is now ready for analysis by LC-MS/MS [43].

Protocol 2: Solid Phase Extraction (SPE) for Pesticides in Water

This protocol is designed for the sensitive detection of 45 pesticides in water samples, achieving method detection limits in the ng/L range [44].

1. Sample Preparation:

- Collect water samples and adjust the pH to 7.0 using a buffer solution.

2. Extraction:

- Pass a known volume of water (e.g., 100 mL to 1 L) through an appropriate SPE column (e.g., reversed-phase C18 or polymer-based).

- The choice of SPE sorbent is critical and should be optimized for the target pesticide panel [44].

3. Elution and Concentration:

- Dry the SPE column by applying vacuum or centrifugal force.

- Elute the captured pesticides with a small volume (e.g., 2-5 mL) of an organic solvent like acetonitrile or methanol.

- Gently evaporate the eluate to dryness under a nitrogen stream and reconstitute the residue in a small volume (e.g., 100-200 µL) of initial mobile phase compatible with the LC-MS/MS method [44].

Quantitative Performance of Optimized Methods

The following table summarizes the achievable performance data from published, optimized protocols for multi-pesticide analysis using LC-MS/MS.

Table 1: Performance Metrics of LC-MS/MS Methods for Pesticide Analysis

| Method Focus | Matrix | Limits of Quantification (LOQ) | Recovery Range | Key Purification Strategy |

|---|---|---|---|---|

| 51 Pesticides [43] | Various Foodstuffs (Fruits, Veg, Meat, etc.) | 0.2 - 9.8 µg/kg | 70.2% - 117.9% | Modified QuEChERS (MWCNTs, SAX, C18) |

| 45 Pesticides [44] | Water & Soil | 0.05 - 18.47 ng/L (Water) | 56.1% - 118.8% (SPE) | Solid Phase Extraction (SPE) |

The Scientist's Toolkit: Essential Research Reagents & Materials

Selecting the right consumables and standards is fundamental for robust and reliable MS/MS analysis.

Table 2: Key Reagents and Materials for MS/MS Experiments

| Item | Function & Purpose | Example Product / Composition |

|---|---|---|

| Pierce HeLa Protein Digest Standard [42] | A complex standard used to verify overall LC-MS/MS system performance, including sample preparation, chromatography, and mass spectrometry. | Commercially available digested protein standard (e.g., Cat. No. 88328). |

| Pierce Peptide Retention Time Calibration Mixture [42] | A set of synthetic peptides used to diagnose and troubleshoot the LC system, gradient stability, and retention time reproducibility. | Commercially available retention time calibration mix (e.g., Cat. No. 88321). |

| Pierce Calibration Solutions [42] | Solutions containing compounds of known mass used to calibrate the mass spectrometer, ensuring mass accuracy and precision. | ESI Positive and Negative Ion Calibration Solutions. |

| LC-MS/MS Grade Solvents [41] | High-purity solvents (water, acetonitrile, methanol) used for mobile phase and sample preparation to minimize chemical noise and background interference. | Commercially certified LC-MS/MS grade solvents. |

| QuEChERS Kits & Adsorbents [43] | Kits containing salts and sorbents for quick, effective sample cleanup. Modified versions with new materials enhance purification for complex matrices. | MgSO4, NaCl, PSA, C18, GCB, plus newer materials like MWCNTs. |

| Inline Filters & Guard Columns [41] | Placed before the analytical column to capture particulates and contaminants, protecting the column from clogging and extending its lifetime. | 0.2 µm frits and short guard columns packed with the same stationary phase as the analytical column. |

Advanced Concepts: Signal Suppression and Enhancement

Matrix effects, particularly ion suppression, are a major challenge in trace analysis. They occur when co-eluting matrix components interfere with the ionization of the target analyte, leading to reduced or enhanced signal.

This technical support guide addresses common challenges in analyzing trace pesticide residues in complex matrices like edible insects, cereals, and spices, providing targeted troubleshooting for researchers focused on optimizing detection limits.

Frequently Asked Questions & Troubleshooting

1. Problem: High matrix interference in spice analysis complicates quantification.

- Question: How can I improve analyte recovery and reduce matrix effects when preparing samples from complex spice matrices like huajiao?

- Solution: Implement an improved multiplug filtration cleanup (m-PFC) method after extraction. This technique efficiently purifies complex samples by using a compact solid-phase purification unit packed with a mixture of adsorbents.

- Recommended Protocol:

- Extraction: Homogenize the spice sample and extract with acetonitrile containing 1% formic acid.

- Dehydration: Add a salt mixture (e.g., 266 mg MgSO4 and 84 mg Na2SO4) to the extract for dehydration.

- Purification: Pass the extract through an m-PFC column containing 40 mg of graphitized carbon black (GCB), 40 mg of C18, and 80 mg of primary secondary amine (PSA). This requires only a 30-second gravity filtration.

- Analysis: Proceed with UHPLC-Q-TOF/MS analysis.

- Justification: This method significantly simplifies purification, reduces organic solvent use, and has been validated for 71 pesticides in huajiao, showing strong correlation (R² ≥ 0.99), acceptable recovery (70.2–119.8%), and excellent sensitivity (LODs 0.0001–0.03 mg/kg) [45].

2. Problem: Inconsistent pesticide recovery from edible insects using generic QuEChERS.

- Question: What modifications are needed for QuEChERS to ensure satisfactory recovery of multiple pesticide classes from lipid-rich edible insects?

- Solution: Optimize the extraction and cleanup steps to account for the high lipid content in many insects. Validation against strict guidelines is crucial.

- Recommended Protocol (for GC-MS/MS):

- Extraction: Use the standard QuEChERS extraction procedure.

- Cleanup: Ensure a robust dispersive-SPE (d-SPE) cleanup step to remove co-extracted fats and fatty acids effectively.

- Validation: The method must be rigorously validated. A protocol for 47 pesticides in insects (bamboo caterpillars, crickets, silkworm pupae) achieved:

- Linearity: R² from 0.9940 to 0.9999.

- Recovery: 70-120% for over 97% of pesticides, with relative standard deviations (RSDs) below 20%.

- Sensitivity: Limits of quantification (LOQs) at 10-15 µg/kg [46].

- Troubleshooting Tip: If recovery is low, experiment with the ratio and composition of d-SPE sorbents (e.g., PSA, C18, GCB) to better manage the specific insect matrix [46].

3. Problem: Unexplained pesticide detection in "wild" versus "farmed" insect samples.

- Question: Our analysis detects pesticides in wild-harvested insects but not in farmed ones. Is this a sampling or instrumental error?

- Solution: This is a consistent finding, not an error. Wild insects are directly exposed to environmental agrochemicals through their diet and habitat, leading to bioaccumulation.

- Evidence from Case Studies:

- A study on African edible insects found residues of nine agrochemicals (insecticides, herbicides, fungicides) in wild-harvested samples. Some samples contained pesticide levels 2 to 49 times higher than the maximum residue limits (MRLs) for meat. In contrast, laboratory-reared insects were free of detectable residues [47].

- Another study on Nigerian crickets detected high concentrations of multiple current-use pesticides (aldicarb, propoxur, chlorpyrifos), underscoring the risk associated with wild-harvesting from contaminated environments [48].

- Recommendation: For a controlled and safer supply, source farmed insects reared under regulated conditions to minimize unpredictable agrochemical contamination [47].

4. Problem: Need for a rapid, sensitive screening method for unknown pesticides.

- Question: Which techniques are best for non-targeted screening and achieving the lowest possible detection limits?

- Solution: Combine advanced Surface-Enhanced Raman Scattering (SERS) with Machine Learning (ML) for rapid, sensitive screening. For confirmatory, high-throughput analysis, use LC-MS/MS or GC-MS/MS.

- SERS with ML Protocol:

- Substrate Preparation: Use citrate-optimized gold nanoparticles (GNPs) to create a SERS-active micro-drop substrate. The tri-sodium citrate (TSC) to gold precursor ratio is critical for maximum signal enhancement.

- Aggregation: Induce GNP aggregation with an electrolyte (e.g., NaCl or HCl) to form 3D "hot-spots."

- Measurement: Perform raster-scanning with a portable spectrometer to improve signal reproducibility.

- Analysis: Analyze spectra with ML models (e.g., PCA, LDA). This approach has achieved >97% classification accuracy for discriminating binary pesticide mixtures (e.g., thiram and phosmet) at trace levels (nM concentrations) [49].

- Advanced Instrumental Analysis: For multi-residue analysis, LC-MS/MS and GC-MS/MS are the gold standards. High-resolution mass spectrometry (HRMS) like UHPLC-Q-TOF/MS is ideal for non-targeted screening and retrospective data analysis [50] [14] [45].

Experimental Protocols for Key Studies

Protocol 1: Multi-Residue Analysis in Edible Insects using GC-MS/MS

This validated method is optimal for detecting a wide panel of pesticides with high sensitivity and precision [46].

- Sample Preparation: Homogenize individual insect specimens into a composite sample. The tested insects included bamboo caterpillars, house crickets, silkworm pupae, giant water bugs, and grasshoppers.

- Extraction: Use a QuEChERS-based extraction method.

- Cleanup: Employ a dispersive-SPE (d-SPE) cleanup step.

- Instrumentation: GC-MS/MS.

- Method Validation Performance:

Parameter Result Pesticides Targeted 47 Linearity (R²) 0.9940 - 0.9999 Limit of Quantification (LOQ) 10 - 15 µg/kg Recovery (at 10, 100, 500 µg/kg) 64.54% - 122.12% (≥97% of pesticides within 70-120%) Relative Standard Deviation (RSD) 1.86% - 6.02% Matrix Effects -33.01% to 24.04% (≥94% of analytes showed minimal effect)

Protocol 2: High-Throughput Analysis in Spices using m-PFC and UHPLC-Q-TOF/MS

This method is designed for complex, challenging matrices like huajiao, enabling rapid and clean analysis [45].

- Sample Types: Applicable to fresh green, dried green, and dried red huajiao.

- Extraction: Extract with acetonitrile containing 1% formic acid.

- Purification: Use the improved m-PFC method with a column containing GCB, C18, and PSA.

- Instrumentation: UHPLC-Q-TOF/MS.

- Method Validation Performance:

Parameter Result Pesticides Targeted 71 Linearity (R²) ≥ 0.99 Recovery 70.2% - 119.8% Limit of Detection (LOD) 0.0001 - 0.03 mg/kg

Research Reagent Solutions

The following table details key reagents and materials essential for the experiments cited in this guide.

| Item Name | Function / Application | Key Details & Rationale |

|---|---|---|

| Citrate-optimized Gold Nanoparticles (GNPs) | SERS substrate for trace detection | Tri-sodium citrate (TSC) acts as both reducing and capping agent. The TSC/Au precursor ratio is critical for maximum SERS enhancement [49]. |

| QuEChERS Kits | Multi-residue pesticide extraction | Standardized kits for extraction and dispersive-SPE cleanup are vital for achieving high recovery in complex matrices like edible insects [46]. |

| m-PFC Columns | Rapid sample cleanup for complex matrices | Packed with GCB, C18, and PSA sorbents; purifies a sample in ~30 seconds via gravity filtration, minimizing solvent use and matrix effects in spices [45]. |

| Graphitized Carbon Black (GCB) | Cleanup sorbent | Effectively removes pigments and planar molecules from matrix extracts, crucial for analyzing colorful spices and insects [45]. |

| Primary Secondary Amine (PSA) | Cleanup sorbent | Removes various polar interferences including fatty acids, sugars, and organic acids, which is essential for lipid-rich insect samples [46] [45]. |

Experimental Workflow for Pesticide Residue Analysis

The diagram below outlines the core decision-making workflow and technical steps for analyzing pesticide residues in different matrices, from sample preparation to final analysis.