POEGMA Polymer Brushes: Conquering Signal Drift for Next-Generation Biosensors and Biomedical Devices

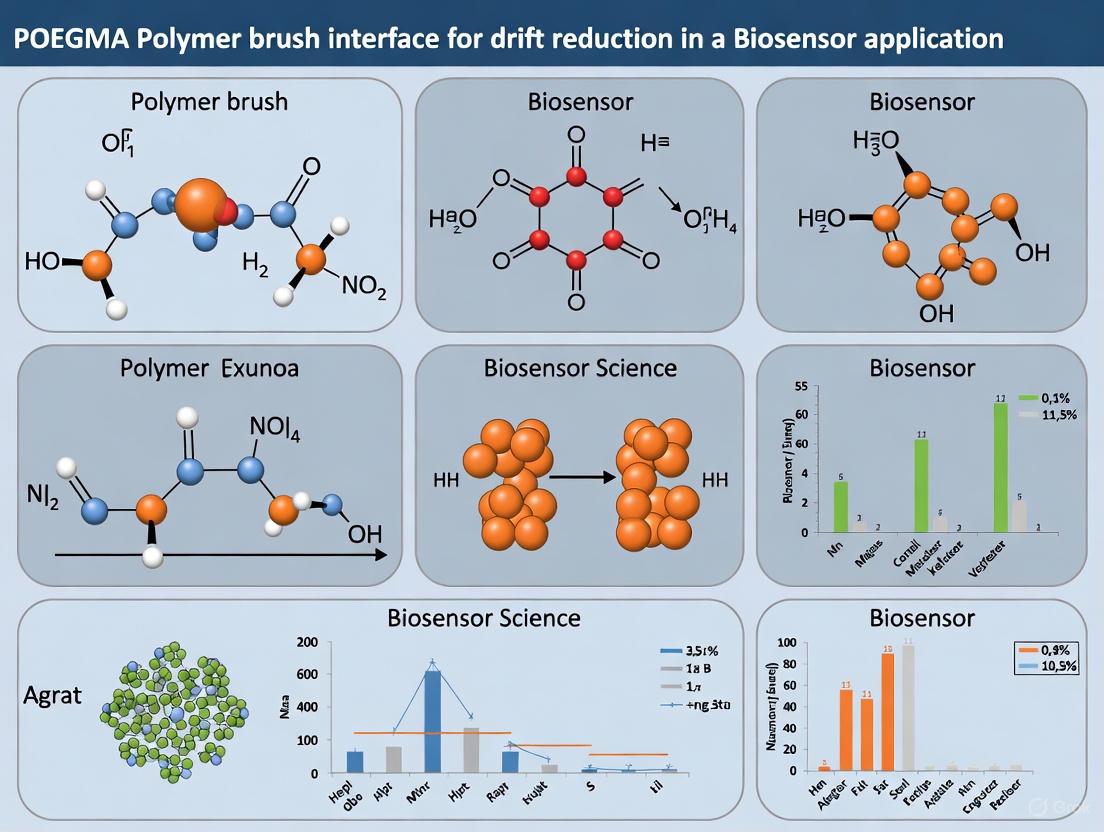

This article explores the transformative role of poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA) polymer brushes in mitigating the pervasive challenge of signal drift in biomedical interfaces.

POEGMA Polymer Brushes: Conquering Signal Drift for Next-Generation Biosensors and Biomedical Devices

Abstract

This article explores the transformative role of poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA) polymer brushes in mitigating the pervasive challenge of signal drift in biomedical interfaces. Tailored for researchers, scientists, and drug development professionals, we delve into the foundational principles of POEGMA, including its unique graft-polymer architecture and exceptional antifouling properties. The discussion progresses to methodological strategies for brush synthesis via surface-initiated ATRP and its direct application in stabilizing biosensors like the D4-TFT immunoassay. We further address critical troubleshooting and optimization parameters, such as controlling structural dispersity and grafting density, and conclude with a validation of POEGMA's performance through comparative analyses against other coatings and its demonstrated efficacy in ultrasensitive, point-of-care diagnostics.

Understanding POEGMA: The Structural and Antifouling Basis for Stable Biointerfaces

Poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA) represents a class of graft (co)polymers that have gained significant importance in advanced material science and biomedical applications. POEGMA features a carbon-carbon polymer backbone with pendant oligo(ethylene glycol) side chains, creating a unique brush-like architecture [1]. This specific structure distinguishes it from linear poly(ethylene glycol) (PEG) and provides exceptional tunability of physicochemical properties, making it particularly valuable for creating stable, non-fouling interfaces in sensitive detection systems [2] [1].

The material's significance has grown substantially in applications requiring precise interface control, notably in biosensor technology where signal drift remains a critical challenge. POEGMA-based polymer brushes have demonstrated remarkable capabilities in mitigating these stability issues while maintaining sensitivity in biologically relevant environments [2].

Molecular Architecture and Synthesis

Graft Polymer Structure

POEGMA belongs to the category of graft or "brush" polymers, characterized by their distinctive molecular architecture:

- Backbone Composition: A carbon-carbon main chain formed through radical polymerization of methacrylate groups

- Side Chain Structure: Pendant oligo(ethylene glycol) chains attached via ester linkages

- Architectural Variants: Can be synthesized as homopolymers, block copolymers, or grafted from various substrates including silicon, gold, and cellulose surfaces [1]

This graft architecture provides multiple sites for hydrogen bonding while maintaining considerable chain flexibility, contributing to its unique interfacial behavior [3].

Synthesis Methods

The most prevalent and controlled synthesis of POEGMA utilizes Atom Transfer Radical Polymerization (ATRP), which enables precise control over molecular weight, polydispersity, and graft density [3] [4] [1].

Table 1: Common ATRP Initiators for POEGMA Synthesis

| Initiator | Catalyst System | Reaction Conditions | End Group | Applications |

|---|---|---|---|---|

| 2-Hydroxyethyl-2-bromoisobutyrate (HEBiB) | CuBr/Bpy | 30°C, 24h in isopropanol | Hydroxyl | Amphiphilic macromolecules [3] |

| 2-Bromoisobutyryl bromide (BiBB) | CuCl/CuBr₂/Bpy | Aqueous conditions, room temperature | Bromine | Surface-initiated brushes [1] |

| Spytag-Bromine (ST-Br) | Copper-based ATRP | Mild aqueous conditions | Spytag peptide | Protein-polymer conjugates [5] |

Representative ATRP Protocol for POEGMA Brushes [1]:

- Surface Preparation: Substrates (e.g., silicon, gold) are functionalized with ATRP initiator molecules, typically bromoisobutyryl derivatives

- Catalyst Preparation: Cu(I)Cl or Cu(I)Br complexed with bipyridine (Bpy) ligands in methanol/water solvent systems

- Monomer:Initiator Ratio: Typically 10:1 to 100:1, depending on target polymer chain length

- Polymerization Conditions: Proceeds at 20-30°C for 12-24 hours under inert atmosphere

- Purification: Extensive washing with solvents to remove catalyst residues and unreacted monomer

This controlled synthesis approach yields POEGMA with narrow molecular weight distributions (PDI < 1.5) and predetermined degrees of polymerization, essential for reproducible interface properties [3].

Key Physicochemical Properties

POEGMA exhibits several critical properties that make it invaluable for interface engineering, particularly in biosensing applications.

Table 2: Key Physicochemical Properties of POEGMA

| Property | Value/Range | Measurement Method | Determining Factors |

|---|---|---|---|

| LCST/VPTT | 23°C to 90°C [6] | DSC, Turbidimetry | Ethylene oxide side chain length, copolymer composition |

| Hydrodynamic Thickness | 15-17 nm (dry) to ~50 nm (swollen) [7] | TIRM, AFM, Ellipsometry | Graft density, molecular weight, solution conditions |

| Protein Resistance | >90% reduction in non-specific adsorption [1] | Fluorescence, SPR, TIRM | Graft density, side chain length, hydration |

| Critical Micelle Concentration | 10⁻⁶ to 10⁻⁷ M (AM applications) [3] | Fluorescence spectroscopy | Hydrophobic/hydrophilic balance, architecture |

Thermal Responsiveness

POEGMA exhibits a lower critical solution temperature (LCST) behavior that can be precisely tuned through molecular design:

- Side Chain Length Dependence: Shorter OEG side chains (n=2) decrease LCST, while longer chains (n=8-9) increase LCST [6]

- Copolymerization Strategy: Statistical copolymerization of di(ethylene glycol) methyl ether methacrylate (M(EO)₂MA, n=2) and OEGMA₄₇₅ (n=8-9) enables fine-tuning of transition temperature [6]

- Volume Phase Transition Temperature (VPTT): For crosslinked POEGMA hydrogels, VPTT can be engineered below (∼23°C), near (∼37°C), or well above (∼90°C) physiological temperature [6]

Solution Behavior and Hydration

POEGMA's interfacial properties are governed by its hydration state and chain conformation:

- Hydrodynamic Boundary Conditions: Recent TIRM studies reveal that POEGMA brushes present a rigid hydrodynamic boundary to approaching particles, despite their compressible nature [7]

- Ionic Strength Response: Nonionic POEGMA brushes exhibit unexpected responses to ionic strength similar to weak polyelectrolyte brushes, contrary to classical theories [7]

- Donnan Potential Effect: In biosensing applications, the POEGMA interface establishes a Donnan equilibrium potential that effectively extends the Debye length in high ionic strength solutions [2]

Application in Drift Reduction for Biosensing

The Signal Drift Challenge in BioFETs

Field-effect transistor-based biosensors (BioFETs) face significant stability challenges in physiological solutions:

- Signal Drift: Temporal changes in output signal caused by slow diffusion of electrolytic ions into the sensing region, altering gate capacitance and threshold voltage [2]

- Debye Length Screening: In high ionic strength solutions (e.g., 1X PBS), the electrical double layer screens charged biomolecules beyond a few nanometers, limiting detection [2]

- Biofouling: Non-specific adsorption of proteins and other biomolecules to sensor surfaces degrades performance over time [1]

POEGMA Mechanism for Enhanced Stability

The D4-TFT platform demonstrates how POEGMA interfaces address these critical challenges [2]:

Key drift reduction mechanisms provided by POEGMA interfaces:

Extended Sensing Distance: POEGMA establishes a Donnan equilibrium potential that effectively increases the Debye length in physiological ionic strength solutions (1X PBS), enabling detection of biomarkers beyond the typical screening length [2]

Stable Electrical Interface: The hydrated POEGMA brush layer minimizes direct contact between the electrolyte solution and transducer surface, reducing ion diffusion and associated signal drift [2]

Biofouling Resistance: The non-fouling properties of POEGMA prevent non-specific protein adsorption, maintaining consistent sensor performance over time [1]

Controlled Testing Methodology: When combined with appropriate electrical testing configurations (infrequent DC sweeps rather than static measurements), POEGMA-enabled devices achieve stable, drift-free operation [2]

Experimental Protocols and Methodologies

POEGMA Brush Formation for Biosensor Interfaces

Protocol: Surface-Initiated ATRP of POEGMA on Biosensor Substrates [2] [1]

Table 3: Research Reagent Solutions for POEGMA Brush Synthesis

| Reagent/Chemical | Function | Specifications | Alternative/Notes |

|---|---|---|---|

| OEGMA Monomer | Primary monomer | Mₙ ~300-475 g/mol, purify through basic alumina column | Available as M(EO)₂MA (n=2) or OEGMA₄₇₅ (n=8-9) |

| ATRP Initiator | Surface initiation | 2-bromoisobutyryl bromide (BiBB) or functional derivatives | Concentration controls graft density |

| Copper(I) Bromide | Catalyst | ≥99.999% purity | Copper(I) chloride as alternative |

| Bipyridine (Bpy) | Ligand | ≥99% purity | PMDETA as alternative ligand |

| Solvent System | Reaction medium | Methanol/water (typically 4:1 v/v) or pure isopropanol | Solvent affects polymerization control |

Step-by-Step Procedure:

Substrate Functionalization:

- Clean substrate (silicon, gold, or CNT-based electrodes) with oxygen plasma treatment

- Immerse in 1-5 mM solution of ATRP initiator (typically bromosilane or thiol derivatives) for 12-24 hours

- Rinse thoroughly with appropriate solvent to remove physisorbed initiator

Polymerization Solution Preparation:

- Dissolve OEGMA monomer (target degree of polymerization 25-100) in degassed methanol/water (4:1 v/v) solvent system

- Add Cu(I)Br catalyst and bipyridine ligand at [Monomer]:[Cu(I)]:[Ligand] ratio of 100:1:2

- Degas solution by purging with nitrogen or argon for 30 minutes

Surface-Initiated ATRP:

- Transfer polymerization solution to reaction vessel containing initiator-functionalized substrate

- Maintain reaction at 20-30°C for 12-24 hours under inert atmosphere

- Monitor conversion by sampling solution aliquots for NMR analysis

Post-Polymerization Processing:

- Remove substrate from reaction mixture and rinse extensively with methanol and water

- Soak in EDTA solution (50 mM) to remove copper catalyst residues

- Store in aqueous buffer or dry under nitrogen stream

Biosensor Functionalization Protocol

Antibody Immobilization in POEGMA Brush Matrix [2]:

- Activation: Treat POEGMA-modified sensor with appropriate coupling agents (e.g., NHS/EDC for carboxyl groups)

- Antibody Printing: Spot capture antibody solutions (0.1-1 mg/mL in PBS) onto defined regions of POEGMA brush layer

- Control Areas: Maintain adjacent regions without antibodies for reference measurements

- Quenching: Block remaining reactive groups with ethanolamine or bovine serum albumin

- Validation: Confirm antibody activity and orientation using fluorescent labeling or antigen binding assays

Characterization Methods for POEGMA Interfaces

Essential Analytical Techniques:

Thickness and Swelling Ratio:

- Ellipsometry: Measure dry and hydrated brush thickness

- TIRM (Total Internal Reflection Microscopy): Quantify hydrodynamic thickness and compressibility in aqueous solutions [7]

Protein Resistance Assessment:

- Fluorescence Microscopy: Incubate with fluorescently labeled proteins (fibrinogen, albumin) and quantify non-specific adsorption

- Surface Plasmon Resonance (SPR): Real-time monitoring of protein adsorption kinetics

Electrical Stability Testing:

- DC Sweep Measurements: Monitor current-voltage characteristics over extended periods in physiological buffer

- Threshold Voltage Tracking: Measure temporal shifts in operating parameters indicative of signal drift [2]

Performance Metrics and Applications

The implementation of POEGMA interfaces in the D4-TFT platform has demonstrated remarkable performance improvements [2]:

- Sensitivity: Sub-femtomolar to attomolar detection limits for biomarkers in undiluted 1X PBS

- Stability: Drift-free operation through combination of POEGMA interface and optimized electrical testing methodology

- Specificity: Minimal non-specific binding confirmed through control devices without capture antibodies

- Point-of-Care Compatibility: Compatible with handheld formats using palladium pseudo-reference electrodes instead of bulky Ag/AgCl references

These advances position POEGMA-based interfaces as critical components in the next generation of reliable, ultrasensitive biosensing platforms for clinical diagnostics, environmental monitoring, and biomedical research.

Polymer brushes, defined as assemblies of polymer chains tethered by one end to a surface, have emerged as a powerful tool for creating antifouling interfaces. Their application is widespread across various formulations, from biomedical devices to biosensors [8]. When these brushes are composed of hydrophilic polymers, they exhibit exceptional resistance to the non-specific adsorption of proteins, peptides, lipids, and microorganisms—a phenomenon collectively known as biofouling [9]. This property is crucial for the performance of medical implants, marine coatings, and diagnostic platforms, where unwanted adsorption can lead to device failure, contamination, or inaccurate readings [10] [9]. For researchers focused on developing robust interfaces, such as the POEGMA (poly(oligo(ethylene glycol) methyl ether methacrylate) polymer brush interface for drift reduction in biosensors, understanding the fundamental antifouling mechanism of hydrated brushes is the foundational first step.

The "Whitesides' rules," which have guided the design of non-fouling materials for decades, outline that effective antifouling polymers should be hydrophilic, capable of forming hydrogen bonds, and electrically neutral [10]. Traditionally, this understanding has centered on two primary categories of antifouling polymer brushes: nonionic derivatives of polyethylene glycol (PEG, considered the "gold standard") and zwitterionic polymers (such as polybetaines) [10]. The mechanism was thought to rely predominantly on short-range interactions, including steric repulsion caused by the compression of polymer brushes as contaminants approach, and the thermodynamic penalty of dehydrating a dense water layer around the brushes [10]. However, recent and surprising findings have revealed that long-range electrostatic interactions, even from seemingly neutral polymer brushes, play a critical and previously overlooked role in their antifouling performance [10]. This application note delves into the multi-faceted antifouling mechanism of hydrated brushes, provides detailed protocols for their preparation and characterization, and frames these insights within the context of developing stable, low-drift biointerfaces.

The Multi-Faceted Antifouling Mechanism

The antifouling performance of hydrated polymer brushes is not the result of a single phenomenon but a combination of several interdependent mechanisms that create a formidable barrier against non-specific adsorption.

The Hydration Layer and Thermodynamic Barrier

A dense hydration layer is the most recognized feature of hydrophilic polymer brushes. Polymers like POEGMA, PHEMA, and zwitterionic types are capable of strongly binding water molecules via hydrogen bonding and ion-dipole interactions, forming a physical and energetic barrier [11] [12]. When a contaminant such as a protein approaches this hydrated layer, fouling requires the displacement of these bound water molecules. This dehydration process is thermodynamically unfavorable, as it incurs a significant energetic penalty, thereby preventing the contaminant from reaching the underlying surface [11] [10]. The water molecules within this layer can rapidly relax and respond fluidly to shear forces, which also contributes to exceptional lubrication properties [12]. For blood-contacting devices, this hydration layer is critical; it minimizes the adsorption of plasma proteins like fibrinogen, thereby preventing the subsequent cascade of platelet adhesion and thrombus formation [11].

Steric Repulsion and Conformational Entropy

Beyond the water layer, the physical presence of the polymer chains themselves provides a steric repulsion barrier. Polymer brushes are not static; they possess significant conformational freedom and mobility. As a contaminant approaches the surface, it compresses the polymer chains, restricting their motion and reducing their available conformational states. This results in a significant loss of entropy, making the adsorption process entropically unfavorable [10]. The effectiveness of this steric barrier is highly dependent on the physical parameters of the brush, particularly its grafting density and brush thickness. High-density, well-defined brushes are more effective at preventing foulants from penetrating through to the substrate, as they present a more uniform and impenetrable physical barrier [11] [13].

The Overlooked Role of Long-Range Electrostatic Interactions

The conventional understanding of PEG-like and zwitterionic brushes has long assumed perfect electrical neutrality. However, recent, direct measurements using highly sensitive techniques like Total Internal Reflection Microscopy (TIRM) have fundamentally challenged this assumption [10]. Studies reveal that surfaces grafted with seemingly "neutral" brushes, such as zwitterionic PCBMA and nonionic POEGMA, can exhibit significant electrostatic interactions with contaminants over distances exceeding hundreds of nanometers [10] [7].

- Evidence of Surface Charge: In TIRM experiments, polystyrene microspheres near PCBMA and POEGMA brushes experience significant long-range repulsion that is highly responsive to ionic strength—a hallmark of electrostatic interaction [10].

- Impact on Contaminant Distribution: This electrostatic repulsion significantly influences the distribution of contaminants like proteins, bacteria, and microalgae near the antifouling surfaces long before short-range steric or hydration forces come into play [10]. For drift reduction in biosensors, this long-range repulsion can help prevent the non-specific adsorption of interfering species that could contribute to background signal noise.

Table 1: Key Antifouling Mechanisms of Hydrated Polymer Brushes

| Mechanism | Spatial Range | Governing Principle | Impact on Fouling |

|---|---|---|---|

| Hydration Layer | Short-Range (Molecular) | Thermodynamic penalty of dehydration | Creates an energetic barrier to adsorption |

| Steric Repulsion | Short-Range (nm scale) | Entropic penalty of chain compression | Physically blocks foulants from penetrating the brush layer |

| Electrostatic Interaction | Long-Range (up to 100s of nm) | Electrostatic repulsion between charged brush and foulant | Influences contaminant distribution and deposition kinetics from a distance |

The following diagram synthesizes these multi-scale interactions into a coherent antifouling process near a polymer brush interface:

Diagram 1: Multi-scale antifouling mechanisms of hydrated polymer brushes. Contaminants experience long-range electrostatic repulsion before encountering short-range hydration and steric barriers.

Experimental Protocols

This section provides detailed methodologies for creating and characterizing antifouling polymer brush surfaces, with a focus on the widely used POEGMA system.

Protocol: Grafting POEGMA Brushes via SI-ATRP

Surface-Initiated Atom Transfer Radical Polymerization (SI-ATRP) is a pivotal technique for growing polymer brushes with precise control over brush thickness, density, and architecture [14] [9]. The following protocol outlines the process for grafting POEGMA brushes onto an initiator-functionalized silicon wafer or glass slide.

- Principle: SI-ATRP is a controlled radical polymerization mediated by a transition metal catalyst (e.g., CuBr/bipyridine). It allows for the "grafting-from" of polymer chains directly from surface-bound initiators, enabling high grafting densities [14] [11].

- Key Applications: Creating non-fouling coatings for biosensors, biomedical implants, and drug delivery systems [9] [13].

Materials & Equipment:

- Substrate: Silicon wafer or glass slide functionalized with ATRP initiator (e.g., using BrTMOS [11]).

- Monomer: Oligo(ethylene glycol) methyl ether methacrylate (OEGMA), purified by passing through a column of activated basic alumina to remove inhibitors [9].

- Catalyst System: Copper(I) bromide (CuBr) and 2,2'-Bipyridine (bipy) as the ligand [9].

- Solvent: Deionized water and methanol mixture (e.g., 4:1 v/v) [9].

- Reaction Environment: Schlenk flask or a sealed reaction vessel with an inert atmosphere (Nitrogen or Argon).

Step-by-Step Procedure:

- Initiator Immobilization: Ensure the substrate (e.g., silicon wafer) is thoroughly cleaned and functionalized with a monolayer of ATRP initiator, such as (3-(2-Bromo-2-methyl)propionyloxypropyl)triethoxysilane (BPE) [14].

- Reactor Preparation: Place the initiator-functionalized substrate into a clean, dry Schlenk flask. Seal the flask with a rubber septum.

- Solution Degassing: In a separate vessel, dissolve the OEGMA monomer (e.g., 10 mmol) in a degassed solvent mixture of water and methanol (e.g., 20 mL total). Add the bipy ligand (e.g., 20.8 mg, 0.133 mmol) and CuBr (e.g., 9.5 mg, 0.066 mmol). Degas the solution by bubbling with inert gas for 30-45 minutes.

- Catalyst Addition: Using a degassed syringe, transfer the monomer/catalyst solution to the Schlenk flask containing the substrate under an inert atmosphere.

- Polymerization Reaction: Place the sealed reactor in a pre-heated oil bath at a defined temperature (e.g., 30°C [9]) and allow the reaction to proceed for a predetermined time (e.g., 1-4 hours) to control brush thickness.

- Reaction Termination: Carefully open the flask to air to terminate the polymerization.

- Substrate Cleaning: Remove the substrate and rinse it extensively with copious amounts of ethanol and deionized water to remove any physisorbed polymer and catalyst residues. Dry the substrate under a stream of nitrogen.

The workflow for this synthesis is illustrated below:

Diagram 2: Workflow for grafting POEGMA brushes via SI-ATRP.

Protocol: Characterizing Antifouling Performance with TIRM

Total Internal Reflection Microscopy (TIRM) is an ultrasensitive technique that can directly measure near-surface interactions and probe the conformation of polymer brushes at the kBT energy level, providing insights into both long-range and short-range forces [10] [7].

- Principle: TIRM uses an evanescent wave generated by total internal reflection to illuminate a colloidal probe particle near a surface. The intensity of scattered light is exponentially dependent on the particle-surface separation distance, allowing for nanometer-scale localization of the particle and statistical reconstruction of the interaction potential [10] [7].

- Key Applications: Directly measuring electrostatic and steric interactions near "neutral" polymer brushes, studying brush swelling/collapse, and characterizing the hindered diffusion of contaminants [10] [7].

Materials & Equipment:

- TIRM Setup: Inverted optical microscope, laser source (e.g., 635 nm), high-sensitivity camera (high frame-rate, e.g., ~400 fps recommended [7]), and a temperature-controlled flow cell.

- Substrate: Polymer brush-grafted glass slide (e.g., POEGMA or PCBMA).

- Probe Particles: Sulfated polystyrene microspheres (commonly used, diameter ~1-5 µm) dispersed in buffer of desired ionic strength [10].

- Solutions: A series of NaCl or buffer solutions with varying ionic strengths (e.g., 0.1 mM to 100 mM).

Step-by-Step Procedure:

- Optical Alignment: Mount the brush-grafted substrate on the microscope stage. Align the laser for total internal reflection at the glass-solution interface and focus the objective on the surface.

- Sample Introduction: Introduce a dilute suspension of probe particles in the desired buffer into the flow cell. Allow particles to settle and diffuse near the surface.

- Data Acquisition: Record a video (e.g., 10-20 seconds at 400 fps) of the scattering intensity of multiple freely-diffusing particles near the surface.

- Particle Tracking: For each video frame, determine the vertical position, h, of each particle from its scattering intensity, I, using the relationship I(h) = I₀ exp(−h/γ), where I₀ is the intensity at contact and γ is the penetration depth [7].

- Interaction Potential Calculation: From the histogram of particle positions, p(h), calculate the interaction potential, ϕ(h), using the Boltzmann inversion principle: ϕ(h) = −kBT ln[p(h)] [10].

- Systematic Variation: Repeat steps 2-5 across a range of ionic strengths to elucidate the presence and strength of electrostatic interactions (evidenced by a decreasing Debye length, κ⁻¹).

- Data Analysis: Fit the repulsive part of the potential curve to an exponential decay (characteristic of electrostatic repulsion) to obtain the Debye length. Analyze the compressibility of the brush layer by comparing optical and hydrodynamic positioning methods [7].

Data Presentation and Analysis

Quantitative data is essential for validating the structure and performance of antifouling brush coatings. The following tables summarize key findings from recent literature.

Table 2: Experimentally Measured Long-Range Interactions via TIRM [10]

| Grafted Surface | NaCl Concentration (mM) | Measured Separation at Potential Minimum, hₘ (nm) | Fitted Debye Length, κ⁻¹ (nm) | Theoretical Debye Length (nm) |

|---|---|---|---|---|

| PCBMA Brush | 0.1 | 322.5 | 31.1 | 30.4 |

| 0.5 | 127.5 | 14.3 | 13.6 | |

| 1.0 | 102.5 | 9.3 | 9.6 | |

| 5.0 | 32.5 | 7.0 | 4.3 | |

| 10.0 | 18.75 | 3.4 | 3.0 | |

| Initiator Only | 0.1 | 267.5 | 30.4 | 30.4 |

| 0.5 | 117.5 | 13.9 | 13.6 | |

| 1.0 | 82.5 | 11.2 | 9.6 |

Table 3: Antifouling Performance of Various Polymer Brush Systems

| Polymer Brush | Substrate | Grafting Method | Protein Adsorption Reduction | Key Application & Finding | Source |

|---|---|---|---|---|---|

| POEGMA | sSEBS-PEDOT conductive fibre mat | SI-ATRP | ~82% (BCA assay vs. pristine mat) | Bioelectronic interfaces; 30-mer brushes showed excellent protein repellency. | [9] |

| PHEMA | Medical-grade PDMS | SI-ATRP | Relative albumin adsorption reduced to 12.2% vs. bare PDMS. | Cardiovascular devices; significant reduction in platelet adhesion. | [11] |

| POEGMA | Printed CNT transistor | Grafted from surface | Enabled sub-femtomolar biomarker detection in 1X PBS. | D4-TFT biosensor; overcomes Debye screening and biofouling. | [2] |

The Scientist's Toolkit

Table 4: Essential Research Reagents and Materials for POEGMA Brush Research

| Item | Typical Specification / Example | Function / Role in Research |

|---|---|---|

| Monomer: OEGMA | Oligo(ethylene glycol) methyl ether methacrylate (Mn = 500 g/mol) | The building block for POEGMA brushes; side chain length influences hydration and non-fouling properties. |

| ATRP Initiator | (3-(2-Bromo-2-methyl)propionyloxypropyl)triethoxysilane (BPE) | Tethered to the substrate surface to initiate the controlled "grafting-from" polymerization. |

| Catalyst System | CuBr / 2,2'-Bipyridine | Mediates the reversible redox cycle in ATRP, enabling controlled radical growth of polymer chains. |

| Probe Particle | Sulfated Polystyrene Microspheres (Ø 1-5 µm) | Acts as a model contaminant or probe in TIRM to measure near-surface interactions with the brush layer. |

| Characterization Substrate | Silicon Wafer / Glass Slide | Provides a smooth, well-defined surface for model studies using ellipsometry, AFM, and TIRM. |

Poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA) represents a significant architectural advancement over traditional linear poly(ethylene glycol) (PEG) for surface engineering and biomedical applications. Unlike linear PEG, POEGMA features a comb-shaped or "bottlebrush" architecture with a hydrophobic carbon-carbon backbone and multiple hydrophilic oligo(ethylene glycol) sidechains [15] [16]. This unique molecular structure confers superior properties including enhanced stability, tunable responsiveness, and exceptional resistance to nonspecific protein adsorption [17] [13]. When covalently grafted to surfaces, POEGMA chains stretch away from the interface due to steric repulsions between neighboring chains, forming what are known as "polymer brushes" [16]. The conformation-function relationships of POEGMA brushes make them particularly valuable for applications requiring precise interface control, such as biosensors, drug delivery systems, and diagnostic devices [15] [2].

Fundamental Advantages Over Traditional PEG

Architectural and Conformational Superiority

The bottlebrush architecture of POEGMA provides fundamental advantages over linear PEG across multiple performance parameters essential for advanced biomedical applications.

Table 1: Comparative Properties of POEGMA Brushes vs. Linear PEG

| Property | POEGMA Brushes | Linear PEG | Significance |

|---|---|---|---|

| Molecular Architecture | Comb-shaped/bottlebrush with carbon backbone | Linear polymer chain | Enhanced structural stability and functional density [15] [18] |

| Protein Resistance | Exceptional, thickness-dependent (>10 nm) | Good, but architecture-dependent | Superior fouling resistance in complex biological fluids [17] [13] |

| Antigenicity | Greatly reduced with EG2-EG3 sidechains | Significant APA response documented | Mitigates immune recognition issues [18] |

| Thermoresponsiveness | Tunable LCST (25-90°C) via sidechain length | Limited | Enables smart materials with temperature-triggered behavior [15] [16] |

| Structural Stability | High; covalently grafted brush configuration | Moderate; physical adsorption common | Enhanced durability for implanted devices and coatings [17] [16] |

| Debye Length Extension | Effective in high ionic strength solutions | Limited | Enables biosensing in physiological conditions [2] |

Mechanisms of Performance Enhancement

The superior performance of POEGMA brushes stems from fundamental physical-chemical mechanisms. The high grafting density of oligo(ethylene glycol) sidechains creates a steric exclusion zone and osmotic pressure that effectively repels proteins and other fouling agents [17] [13]. POEGMA's comb-shaped structure enables independent control over main-chain and side-chain conformations, allowing researchers to precisely tune from extended to collapsed states in response to environmental stimuli [15]. This conformational control is the driving force behind POEGMA's programmable thermosensitivity, supramolecular assembly characteristics, and efficient protein repellency [15].

Additionally, POEGMA brushes effectively address the growing concern of anti-PEG immunity. While linear PEG can trigger immune responses and anti-PEG antibody (APA) production, POEGMA brushes with shorter sidechain lengths (particularly EG2 and EG3) demonstrate significantly reduced antigenicity while maintaining excellent stealth properties [18]. This architectural advantage enables continued use of PEG-derived chemistry while circumventing immunological complications that have emerged with traditional PEGylated products.

Application in Drift-Reduced Biosensing

The D4-TFT Platform for Ultrasensitive Detection

The exceptional properties of POEGMA brushes have enabled groundbreaking advances in biosensing technology, particularly in addressing the persistent challenges of signal drift and charge screening in biological field-effect transistors (BioFETs). The D4-TFT platform represents a transformative approach that leverages POEGMA brushes to achieve unprecedented sensitivity and stability in point-of-care diagnostic formats [2].

This biosensing platform incorporates POEGMA brushes as an essential interface component that simultaneously addresses multiple technical barriers: Debye length screening effects at physiological ionic strengths, signal drift from ion diffusion, and nonspecific binding that compromises assay specificity [2]. The platform operates through four sequential steps: Dispense (sample application), Dissolve (rehydration of printed reagents), Diffuse (lateral flow across surface), and Detect (electrical or optical readout) [19].

Table 2: POEGMA Brush Performance in D4-TFT Biosensing Platform

| Parameter | Challenge | POEGMA Brush Solution | Performance Outcome |

|---|---|---|---|

| Debye Length Screening | Limited detection range in physiological buffers | Polymer brush extends sensing distance via Donnan potential | Enabled detection in 1X PBS (physiological ionic strength) [2] |

| Signal Drift | Temporal signal variations from ion diffusion | Maximized sensitivity through passivation and stable testing configuration | Stable baseline for reliable sub-femtomolar detection [2] |

| Non-Specific Binding | Fouling from complex samples (e.g., blood, serum) | Exceptional protein resistance of brush coating | High signal-to-noise ratio in complex biological fluids [2] [17] |

| Assay Sensitivity | Detection limit constraints in point-of-care formats | Enhanced binding capacity and specificity | Attomolar-level detection sensitivity demonstrated [2] |

Mechanism of Signal Drift Mitigation

POEGMA brushes address signal drift through multiple complementary mechanisms. First, the brush architecture creates a stable interfacial environment that minimizes nonspecific interactions and reduces the gradual accumulation of interferents that contribute to baseline drift [2]. Second, the controlled grafting chemistry enables optimal passivation of sensing elements, particularly when combined with appropriate encapsulation strategies to mitigate leakage currents [2]. Third, the extension of the effective Debye length through the Donnan potential effect allows for operation in undiluted physiological buffers, eliminating the dilution-induced artifacts that often mask drift phenomena in conventional biosensors [2].

The implementation of POEGMA brushes in the D4-TFT platform has demonstrated remarkable performance, achieving attomolar-level detection of biomarkers in 1X PBS while simultaneously showing no signal change in control devices lacking specific capture agents within the same chip environment [2]. This level of sensitivity and specificity, combined with minimal drift, represents a significant advancement toward reliable point-of-care diagnostic systems.

Experimental Protocols

Surface-Initiated Atom Transfer Radical Polymerization (SI-ATRP) of POEGMA Brushes

Principle: SI-ATRP allows controlled growth of polymer brushes with precise thickness and density from initiator-functionalized surfaces. This method provides uniform POEGMA coatings with controllable film thicknesses under relatively mild experimental conditions [18] [16].

Materials:

- Substrates: Gold-coated sensors (2-15 nm Au on glass) or glass slides

- Initiator: ω-Mercaptoundecylbromoisobutyrate (for gold) or brominated silane initiator (for glass)

- Monomer: OEGMA (varying molecular weights: 144, 188, or 300 g/mol)

- Catalyst: CuCl/CuBr₂ with 2,2'-dipyridyl (bpy) ligand

- Reducing agent: Ascorbic acid (for ARGET ATRP)

- Solvent: Deionized water or water-methanol mixtures

Procedure:

- Surface Preparation: Clean substrates thoroughly with oxygen plasma treatment for 15 minutes.

- Initiator Immobilization: Incubate substrates in 10 mM initiator solution in ethanol overnight for thiol-gold bonding or silanization for glass substrates [16].

- Polymerization Solution Preparation: Prepare degassed mixture of OEGMA monomer (varies by target sidechain length), catalyst (CuCl/CuBr₂/bpy), and reducing agent in deoxygenated solvent [18] [16].

- Brush Growth: Transfer solution to reaction chamber containing initiator-functionalized substrates. Polymerize for 2-5 hours at room temperature under inert atmosphere.

- Characterization: Measure brush thickness by ellipsometry (typically >10 nm for optimal non-fouling performance) [18].

Critical Parameters:

- Monomer molecular weight determines sidechain length and final brush thickness [16]

- Polymerization time and initiator density control brush thickness and density [13]

- Oxygen-free environment is essential for controlled living polymerization

QCM-D Analysis of POEGMA Phase Transition

Principle: Quartz Crystal Microbalance with Dissipation (QCM-D) enables real-time, in-situ monitoring of polymer brush growth and temperature-responsive behavior by measuring changes in resonance frequency and energy dissipation [16].

Materials:

- QCM-D sensors (gold-coated quartz crystals)

- POEGMA-functionalized QCM-D sensors (from Protocol 4.1)

- QCM-D instrument with temperature control module

- Phosphate buffered saline (PBS, 1X)

Procedure:

- Sensor Preparation: Synthesize POEGMA brushes directly on QCM-D sensors following Protocol 4.1.

- Baseline Establishment: Flow PBS buffer through chamber at 100 μL/min until stable frequency baseline is achieved.

- Temperature Ramping: Increase temperature from 24°C to 65°C at 1°C/min rate while continuously monitoring frequency and dissipation shifts [16].

- Isothermal Holding: Maintain temperature at 65°C for 2 minutes to ensure complete brush collapse.

- Cooling Phase: Decrease temperature from 65°C to 24°C at 1°C/min to observe swelling behavior.

- Cycling: Repeat temperature cycles (typically 10x) to demonstrate reversibility [16].

Data Analysis:

- Frequency shift (Δf) correlates with mass changes during swelling/collapse

- Dissipation shift (ΔD) indicates changes in viscoelastic properties

- LCST determination from inflection point in frequency-temperature plot

Fabrication of POEGMA-Based Biosensors

Principle: This protocol describes the creation of the D4-TFT biosensing platform that leverages POEGMA brushes for drift-resistant biomarker detection [2].

Materials:

- POEGMA brush-coated substrates (from Protocol 4.1)

- Capture antibodies specific to target analyte

- Poly(dimethylsiloxane) (PDMS) microfluidic channels

- Carbon nanotube (CNT) thin-film transistors

- Palladium (Pd) pseudo-reference electrodes

- Trehalose-based excipient ink for reagent storage

Procedure:

- Surface Activation: Treat POEGMA brush surfaces with oxygen plasma to create limited reactive sites while maintaining non-fouling properties.

- Antibody Patterning: Inkjet-print capture antibodies in defined array patterns onto POEGMA surface using non-contact dispenser [2] [19].

- Detection Antibody Storage: Print detection antibodies conjugated with signal transducers onto dissolvable trehalose layer adjacent to sensing area.

- Device Integration: Align and bond PDMS microfluidic channels to create flow paths for sample delivery.

- Electronic Integration: Connect CNT thin-film transistors and Pd pseudo-reference electrodes to complete electrical sensing circuit [2].

- Quality Control: Verify antibody activity and brush integrity after fabrication using fluorescence labeling.

Critical Applications:

- Point-of-care diagnostics for infectious diseases (malaria, HIV, Ebola) [19]

- Cancer biomarker detection (hepatocellular carcinoma) [19]

- SARS-CoV-2 variant monitoring and neutralizing antibody assessment [19]

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for POEGMA Brush Research and Applications

| Reagent/Chemical | Function/Application | Specifications & Notes |

|---|---|---|

| OEGMA Monomers | Building blocks for brush synthesis | Varying sidechain lengths: OEGMA-144, OEGMA-188, OEGMA-300 (numbers indicate molecular weight) [16] |

| ATRP Initiator | Surface anchoring for brush growth | ω-Mercaptoundecylbromoisobutyrate for gold; brominated silanes for glass/oxide surfaces [16] |

| Copper Catalyst | Mediates controlled radical polymerization | CuCl/CuBr₂ with 2,2'-dipyridyl ligand; ascorbic acid for ARGET ATRP [18] |

| POEGMA-Coated QCM-D Sensors | Real-time monitoring of brush behavior | Gold-coated quartz crystals with grafted POEGMA for phase transition studies [16] |

| Anti-PEG Antibodies | Antigenicity assessment | Mouse monoclonal (APA-1,2,3,5,6E) for evaluating immune recognition [18] |

| Extracellular Matrix Proteins | Cell patterning studies | Collagen I, fibronectin, laminin for creating defined microenvironments [17] |

| Clinical Plasma Samples | Validation in biological matrices | APA-positive samples from PEG-treated patients for real-world assessment [18] |

Advanced Characterization Techniques

Understanding POEGMA brush architecture and behavior requires sophisticated characterization methodologies that probe structural, mechanical, and dynamic properties.

Total Internal Reflection Microscopy (TIRM)

TIRM has emerged as a powerful technique for characterizing the swelling and collapse of polymer brushes in aqueous solutions with exceptional sensitivity. This approach enables measurement of near-wall hindered diffusion of tracer particles, providing insights into brush compressibility and conformational changes in response to environmental stimuli [7].

Key Findings: TIRM analysis has revealed that POEGMA brushes exhibit unexpected responses to ionic strength similar to weak polyelectrolyte brushes, contrary to classical theoretical predictions [7]. The technique can detect differences between optical and hydrodynamic positioning of particles near brush surfaces, with the discrepancy (Δh = hoptical - hhydro) indicating the compressibility of the brush layer under particle loading.

Multi-Technique Validation

Complementary characterization approaches provide comprehensive understanding of POEGMA brush properties:

- Ellipsometry: Precisely measures brush thickness in dry and hydrated states, with >10 nm thickness typically required for optimal non-fouling performance [18]

- Atomic Force Microscopy (AFM): Visualizes surface morphology and can probe mechanical properties through force-distance measurements [17] [7]

- Surface Plasmon Resonance (SPR): Quantifies protein adsorption in real-time with exceptional sensitivity [17]

- Neutron Reflectometry: Provides detailed information about brush architecture and nucleic acid infiltration depth in gene delivery complexes [20]

Visualizing POEGMA Brush Mechanisms

The following diagram illustrates the mechanism by which POEGMA brushes reduce signal drift and enhance biosensing performance in the D4-TFT platform:

POEGMA brushes represent a transformative advancement over traditional linear PEG for interface engineering in biomedical applications. Their unique bottlebrush architecture enables unprecedented control over surface properties, addressing critical challenges in biosensing, drug delivery, and diagnostic technologies. The conformations of POEGMA brushes serve as the fundamental driving force behind their exceptional thermosensitivity, supramolecular assembly characteristics, and protein-repellent capabilities [15].

The implementation of POEGMA brushes in the D4-TFT platform demonstrates how architectural control at the molecular level translates to macroscopic performance benefits, particularly in addressing signal drift and enabling attomolar-level detection in physiologically relevant conditions [2]. Furthermore, the reduced antigenicity of optimized POEGMA architectures with shorter sidechains (EG2-EG3) provides a strategic path forward for circumventing the emerging challenges of anti-PEG immunity that threaten conventional PEGylated products [18].

As research continues to elucidate the complex relationship between POEGMA brush architecture and function, these materials are poised to enable increasingly sophisticated biomedical technologies that operate with enhanced sensitivity, specificity, and reliability in complex biological environments.

In biomedical devices, from biosensors to implantable diagnostics, long-term signal stability is a paramount concern. A primary source of signal degradation, or drift, is the nonspecific adsorption of biomolecules (proteins, lipids, cells) onto the device's surface—a phenomenon known as biofouling [9]. This fouling layer obfuscates the sensing interface, leading to increased noise, reduced sensitivity, and unreliable data. Poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA) polymer brushes have emerged as a powerful interface engineering strategy to combat this issue. This application note details how the robust antifouling properties of POEGMA brushes are critically linked to the reduction of signal drift, providing researchers with protocols and data to implement this stabilizing technology.

The efficacy of POEGMA brushes stems from their unique graft-polymer structure. A polymethacrylate backbone is tethered to the surface, while multiple oligo(ethylene glycol) side chains extend into the aqueous environment, creating a dense, hydrated brush [21]. This structure provides antifouling through a combination of steric repulsion, the formation of a protective hydration barrier, and chemical neutrality [9]. Recent research has uncovered that electrostatic interactions, even in seemingly neutral brushes, play a significant and previously underestimated long-range role in preventing the initial approach of contaminants, thereby preserving signal integrity from the earliest stages of deployment [10].

Quantitative Analysis: Correlating Antifouling Performance with Signal Stability

The performance of POEGMA brushes can be quantitatively evaluated using several metrics. The following table summarizes key experimental data that directly correlates brush properties with antifouling efficacy and, by extension, signal stability.

Table 1: Quantitative Antifouling Performance of POEGMA Brush Coatings

| Material/Coating | Grafting Technique | Key Antifouling Metric | Result | Implication for Signal Stability |

|---|---|---|---|---|

| POEGMA on sSEBS-PEDOT fibre mats [9] | SI-ATRP | Protein Adsorption (BCA Assay) | ~82% of proteins repelled | Drastic reduction in fouling-induced noise on conductive interfaces. |

| POEGMA brushes (Low Salt) [10] | TIRM Measurement | Long-Range Repulsion Distance | >300 nm | Prevents contaminants from approaching, reducing initial adhesion that leads to drift. |

| POEGMA brushes (High Salt) [10] | TIRM Measurement | Equilibrium Distance (hm) | Decreased with ionic strength | Guides design for specific physiological environments (e.g., blood, serum). |

| POEGMA@AuNPs (Homogeneous) [21] | DLS & UV-vis | Colloidal Stability in PBS | Stable for several days | Ensures durability and consistent performance of nanoscale sensors and probes. |

Further analysis of the brush structure itself is critical, as properties like the dispersity of the OEG side chains have a direct impact on performance. Homogeneous brushes offer superior stability.

Table 2: Impact of POEGMA Brush Structure on Physicochemical Properties

| Structural Property | Polymer Brush Type | Experimental Observation | Impact on Biofouling and Signal Stability |

|---|---|---|---|

| Homogeneous OEG Chains (POEG8MA) [21] | Structurally homogeneous brushes from discrete macromonomers | Enhanced colloidal stability across a wide temperature range; reduced immunogenicity. | More predictable and stable antifouling performance; reduced risk of antibody-driven fouling. |

| Heterogeneous OEG Chains (POEGpMA) [21] | Structurally polydisperse brushes from commercial mixtures | Promoted binding of anti-PEG antibodies; reduced hydration. | Higher risk of immune recognition and fouling, potentially leading to increased drift. |

| High Grafting Density [9] | Dense brush layer from optimized SI-ATRP | High protein repellence (>80%). | Creates a formidable steric and hydration barrier, crucial for long-term signal stability. |

Experimental Protocols

Protocol: Grafting POEGMA Brushes via Surface-Initiated ATRP (SI-ATRP)

This protocol describes the functionalization of a conductive electrospun fiber mat (sSEBS-PEDOT) with POEGMA brushes to create a fouling-resistant biointerface [9].

Research Reagent Solutions:

- Monomer: Oligo(ethylene glycol) methyl ether methacrylate (OEGMA, Mn ~300 or ~500 g/mol).

- ATRP Initiator: (3,4-Ethylenedioxythiophene) methyl 2-bromopropanoate (EDOTBr), synthesized from (2,3-dihydrothieno[3,4-b][1,4]dioxin-2-yl)methanol and 2-bromopropionyl bromide [9].

- Catalyst System: Copper(II) bromide (CuBr) and 2,2'-Bipyridine (bpy) in a suitable solvent (e.g., acetonitrile).

- Substrate: Sulfonated polystyrene-block-poly(ethylene-ran-butylene)-block-polystyrene infused with PEDOT (sSEBS-PEDOT).

Procedure:

- Surface Initiation Preparation: Electropolymerize a thin copolymer film of EDOT and EDOTBr onto the sSEBS-PEDOT fiber mat. This creates a surface uniformly coated with ATRP initiating sites (the bromopropanoate groups from EDOTBr).

- Polymerization Solution Preparation: In a Schlenk flask, dissolve the OEGMA monomer in a degassed solvent. Add the ligand (2,2'-bipyridine) and the copper catalyst (CuBr). Purge the mixture with an inert gas (e.g., N2) to remove oxygen.

- SI-ATRP Grafting: Immerse the initiator-coated substrate into the polymerization solution. Seal the reaction vessel and place it in a temperature-controlled environment (e.g., 30-40°C) for a predetermined time (e.g., 1-4 hours) to control brush length.

- Termination and Washing: Carefully remove the substrate from the solution and rinse it thoroughly with a solvent (e.g., ethanol) and deionized water to terminate the reaction, remove any physisorbed catalyst, and recover the final POEGMA-grafted substrate.

The following workflow diagram illustrates the key steps of this protocol:

Protocol: Direct Measurement of Long-Range Interactions via Total Internal Reflection Microscopy (TIRM)

This protocol uses TIRM to directly measure the kBT-level interactions between a colloidal probe and a POEGMA brush surface, quantifying the long-range forces that contribute to antifouling and signal stability [10].

Research Reagent Solutions:

- Functionalized Substrate: A glass slide grafted with POEGMA brushes via ATRP.

- Colloidal Probe: Sulfated polystyrene microspheres (commonly 1-5 µm in diameter) which possess a strong, well-defined surface charge.

- Buffer Solutions: A series of NaCl solutions (e.g., 0.1 mM to 10 mM) to vary ionic strength.

Procedure:

- Optical Setup: Configure the TIRM apparatus. A laser beam is directed through a prism and onto the POEGMA-grafted substrate at an angle greater than the critical angle for total internal reflection, creating an evanescent wave field that decays exponentially from the surface.

- Sample Chamber Assembly: Place the POEGMA substrate and a dilute suspension of the sulfated PS microspheres in the desired ionic strength buffer into a sample chamber on the prism.

- Data Acquisition: As a microsphere diffuses freely near the brush surface within the evanescent field, it scatters light with an intensity inversely proportional to its distance from the surface. Record the scattering intensity, I(t), over time (typically tens of minutes).

- Data Analysis: Convert the intensity time-series, I(t), into a distance time-series, h(t). From the probability distribution of the particle's position, P(h), calculate the mean force and the interaction potential profile, U(h), using the Boltzmann inversion principle: U(h) = -kBT ln[P(h)].

The Stabilization Mechanism: From Molecular Interactions to Stable Signals

The exceptional signal stability provided by POEGMA brushes is not the result of a single mechanism, but a synergistic combination of short- and long-range interactions.

The following diagram illustrates the multi-scale defense mechanism of POEGMA brushes against biofouling, which is the foundation for long-term signal stability.

Long-Range Electrostatic Repulsion: Contrary to the long-held assumption of perfect charge neutrality, surfaces grafted with POEGMA and similar brushes exhibit a measurable surface charge, leading to significant electrostatic interactions [10]. TIRM measurements reveal repulsive forces acting on negatively charged probes at distances exceeding 300 nm in low ionic strength environments. This long-range barrier prevents contaminants from even reaching the short-range defense zone, drastically reducing the fouling rate and its associated drift.

Short-Range Steric Hindrance: As a contaminant overcomes the long-range barrier and approaches within the brush layer (typically <20 nm), it must compress the densely grafted polymer chains. This compression is entropically unfavorable, generating a strong repulsive force [10] [9].

Hydration Layer Formation: The oligo(ethylene glycol) side chains are highly hydrophilic and form a tightly bound water layer through hydrogen bonding. Displacing this water to allow for contaminant adsorption is thermodynamically costly, creating a further energy barrier to fouling [10] [22].

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for POEGMA Brush Research

| Reagent / Material | Function / Role | Key Consideration for Research |

|---|---|---|

| OEGMA Monomer (e.g., Mn 300 or 500) [21] | The building block for the polymer brush. | Commercial OEGMA is polydisperse. Use flash chromatography to isolate discrete chain lengths (e.g., OEG8MA) for homogeneous brush properties. |

| ATRP Initiator (e.g., EDOTBr or silane-based) [9] | Provides the covalent anchor point from which polymer chains grow. | Must be matched to the substrate material (e.g., EDOTBr for conductive polymers, silanes for glass/oxides). |

| Copper Catalyst System (CuBr/CuCl & bipyridine) [9] | Mediates the controlled radical polymerization. | Oxygen must be rigorously excluded. Consider ARGET-ATRP for lower catalyst loading and easier handling [21]. |

| Sulfated Polystyrene Microspheres [10] | Act as well-defined colloidal probes for TIRM. | Possess high, stable surface charge, ideal for measuring weak long-range electrostatic interactions. |

| Total Internal Reflection Microscopy (TIRM) [10] | Technique to directly measure kBT-level interaction potentials near surfaces. | Provides unparalleled resolution of long-range forces, challenging assumptions about "neutral" brushes. |

The integration of POEGMA brushes onto biosensing interfaces provides a robust, multi-faceted defense against biofouling, which is the critical link to achieving long-term signal stability. By combining potent short-range steric and hydration barriers with a newly appreciated long-range electrostatic component, these polymer brushes effectively shield the interface from contaminating biomolecules. The protocols and data outlined herein provide a roadmap for researchers to implement and characterize this powerful technology, ultimately leading to more reliable and durable biomedical devices, biosensors, and diagnostic platforms.

Synthesis and Implementation: Crafting POEGMA Brushes for Real-World Drift Reduction

Surface-Initiated Atom Transfer Radical Polymerization (SI-ATRP) is a pivotal controlled radical polymerization technique essential for growing polymer brushes from solid substrates. This method originates from the broader ATRP methodology, which employs a reversible redox process mediated by transition metal catalysts to control radical polymerization [14]. SI-ATRP extends this precise mechanism to surfaces, enabling the grafting of polymer chains with controlled thickness, density, and architecture directly from substrate interfaces [23]. The technique has become a cornerstone in surface and interface engineering, driving innovation in nanotechnology, biotechnology, and materials engineering [14].

For research focused on developing stable interfaces, such as POEGMA (poly[(oligoethylene glycol)methacrylate]) brush coatings for drift reduction, SI-ATRP provides the necessary molecular-level control to tailor interfacial properties. The robust nature of brushes synthesized via SI-ATRP makes them particularly attractive for applications requiring precise control over bio-nano interactions, including drug delivery systems, diagnostic tools, and antifouling coatings [24].

Fundamental Principles of SI-ATRP

Reaction Mechanism

SI-ATRP operates via a reversible redox catalytic cycle (Figure 1) where a transition metal complex (typically copper-based) mediates the equilibrium between active radical species and dormant alkyl halides [25]. This dynamic equilibrium enables controlled chain growth while suppressing premature termination.

- Activation: The catalyst in its lower oxidation state (e.g., Cu(^I)/L) reacts with a dormant, surface-tethered alkyl halide initiator (R-X), generating an active propagating radical (R•) and the oxidized metal halide complex (X-Cu(^II)/L).

- Propagation: The activated radical (R•) adds to monomer units, leading to chain growth.

- Deactivation: The growing radical chain is rapidly deactivated by the higher oxidation state metal complex (X-Cu(^II)/L), reforming the dormant species (P(_n)-X) and regenerating the Cu(^I)/L activator.

This cycle maintains a low concentration of active radicals, favoring propagation over termination reactions and allowing for the synthesis of well-defined polymer brushes with narrow molecular weight distributions [23] [25].

Figure 1. SI-ATRP Catalytic Cycle. The diagram illustrates the reversible activation-deactivation equilibrium between dormant alkyl halide species and active radicals, mediated by a copper catalyst.

Grafting Strategies

Polymer brushes can be attached to surfaces primarily through three approaches, with the "grafting-from" method being the most prominent for SI-ATRP (Figure 2) [23] [24].

- Grafting-From: This approach involves immobilizing ATRP initiator molecules on the substrate surface, followed by polymer chain growth directly from these anchored sites. Its primary advantage is the ability to achieve high grafting densities, as monomer molecules can diffuse more easily to the growing chain ends than a pre-formed polymer could attach to the surface against steric repulsion [23] [24].

- Grafting-To: Pre-synthesized, end-functionalized polymer chains are attached to a complementary functional group on the substrate. While this allows for thorough polymer characterization before grafting, it often results in lower brush density due to steric hindrance preventing chains from approaching the surface once initial grafting has occurred [23] [24].

- Grafting-Through: A surface-functionalized macromonomer is copolymerized with free monomer in solution. This method typically yields the lowest grafting density among the three approaches and is less commonly used [23].

Figure 2. SI-ATRP Grafting-From vs. Grafting-To. The grafting-from method used in SI-ATRP overcomes steric limitations, enabling high-density brush formation crucial for stable interfaces.

Quantitative Parameters in SI-ATRP

Successful execution of SI-ATRP requires careful control of several quantitative parameters that determine the final properties of the polymer brush.

Table 1: Key Quantitative Parameters in SI-ATRP

| Parameter | Typical Range/Value | Impact on Brush Properties |

|---|---|---|

| Catalyst Concentration | ~917 ppm [23] to 10,000 ppm [23] | Influences polymerization rate and control; lower concentrations possible with advanced techniques (ARGET, ICAR) [24]. |

| Equilibrium Constant (KATRP) | Spans >107 for different catalysts [25] | Determines balance between active and dormant species; crucial for molecular weight control and low dispersity. |

| Grafting Density | Varies with initiator concentration [23] | Determines brush conformation: "mushroom" at low density to extended "brush" at high density [26]. |

| Molecular Weight Dispersity (Đ) | <1.5 (controlled polymerization) [23] | Indicates level of control; lower Đ signifies uniform chain lengths. |

| Polymer Brush Thickness | Nanometer to micrometer scale [24] | Controlled by monomer conversion and reaction time; determines layer properties and functionality. |

Experimental Protocol: Synthesis of POEGMA Brushes via SI-ATRP

This protocol details the synthesis of structurally homogeneous POEGMA brushes from flat silicon substrates, a critical consideration for drift reduction research. Structural homogeneity in OEG side chains has been shown to enhance brush hydration and reduce adhesion, which are key properties for stable interfaces [27].

Research Reagent Solutions

Table 2: Essential Materials and Reagents

| Reagent/Material | Function | Specific Example/Note |

|---|---|---|

| Silicon Wafer/Substrate | Base substrate for brush growth | Requires surface hydroxyl groups for initiator immobilization. |

| Initiator Silane | Anchors polymerization initiator to surface | e.g., (3-(2-Bromoisobutyryl)oxypropyl)dimethylethoxysilane (BIDS) [14]. |

| Discrete OEGMA Monomer | Building block for brushes | Use chromatographically purified OEGMA for homogeneous side chains [27]. |

| Copper(I) Bromide (CuBr) | Catalyst (activator) | Must be of high purity; stored under inert conditions. |

| PMDETA Ligand | Binds to copper, modulating catalyst activity | N,N,N',N'',N''-Pentamethyldiethylenetriamine [23]. |

| Copper(II) Bromide (CuBr₂) | Deactivator | Added to improve reaction control. |

| Anisole/Solvent | Reaction medium | Provides appropriate polarity for monomer and catalyst solubility. |

Step-by-Step Procedure

Step 1: Substrate Preparation and Initiator Immobilization

- Clean silicon substrates thoroughly with oxygen plasma or piranha solution to generate a uniform layer of surface hydroxyl groups.

- Immerse the substrates in a 1-2 mM solution of the initiator silane (e.g., BIDS) in dry toluene under an inert atmosphere.

- React for 12-24 hours at room temperature to form a covalently bound initiator monolayer.

- Rinse sequentially with toluene, ethanol, and acetone to remove physisorbed silane, then dry under a stream of nitrogen.

Step 2: SI-ATRP Reaction Setup

- In a Schlenk flask or glass reactor, charge the discrete OEGMA monomer and anhydrous anisole (typical monomer:solvent ratio of 1:1 to 1:3 v/v).

- Degass the solution by purging with nitrogen or argon for 30-45 minutes.

- In a separate vessel, prepare the catalyst complex by premixing CuBr and the ligand (PMDETA) in a degassed solvent.

- Add a small, controlled amount of CuBr₂ (deactivator) to the catalyst solution to establish the ATRP equilibrium rapidly.

Step 3: Polymerization

- Transfer the initiator-functionalized substrate to the reaction vessel.

- Add the degassed monomer/solvent mixture to the catalyst complex under a positive pressure of inert gas.

- Quickly transfer the final reaction mixture to the vessel containing the substrate and seal it.

- Allow the polymerization to proceed at a set temperature (e.g., 60-70°C) for a predetermined time (2-24 hours) to achieve the target brush thickness.

Step 4: Work-up and Characterization

- Carefully remove the substrate from the reaction mixture and rinse thoroughly with the solvent (e.g., ethanol, water) to remove all physisorbed polymer and catalyst residues.

- Characterize the resulting POEGMA brush using ellipsometry (thickness), contact angle goniometry (wettability), X-ray photoelectron spectroscopy (composition), and atomic force microscopy (morphology).

The entire experimental workflow is summarized in Figure 3.

Figure 3. POEGMA Brush Synthesis Workflow. The process from substrate preparation to final brush characterization, highlighting key steps for creating a stable interface.

Critical Considerations for POEGMA Brush Interfaces

The performance of POEGMA brushes in drift reduction applications is highly dependent on their structural characteristics.

Impact of Structural Dispersity: Recent research demonstrates that the structural dispersity of OEG side chains—the heterogeneity in their length—significantly affects interfacial properties. Brushes synthesized from discrete, chromatographically purified OEGMA monomers exhibit increased hydration and reduced adhesion compared to those made from commercially available polydisperse monomers. This is attributed to minimized hydrophobic interactions and enhanced water association in structurally homogeneous brushes [27]. For drift reduction, this implies that using discrete monomers can lead to more lubricious and stable interfaces.

Architecture and Grafting Density: The conformation of polymer brushes is governed by grafting density and molecular weight. At high grafting densities, chains are forced to stretch away from the surface, forming a dense, extended brush layer ideal for creating a uniform, defect-free interface that minimizes nonspecific interactions [26]. SI-ATRP excels at producing such high-density brushes.

Troubleshooting and Optimization

Common challenges in SI-ATRP and their solutions are listed below.

Table 3: SI-ATRP Troubleshooting Guide

| Problem | Possible Cause | Solution |

|---|---|---|

| Uncontrolled Polymerization | Oxygen contamination, insufficient deactivator (CuII). | Rigorous degassing; optimize [CuII]/[CuI] ratio. |

| Low Grafting Density | Inefficient initiator immobilization. | Ensure substrate is thoroughly cleaned and hydroxylated; use fresh initiator solution. |

| Non-uniform Brush | Inhomogeneous initiator layer or catalyst precipitation. | Improve initiator deposition method; ensure ligand provides a stable complex. |

| Insufficient Brush Thickness | Reaction time too short, low catalyst activity. | Increase polymerization time; consider a more active ligand (e.g., Me6TREN). |

The pursuit of point-of-care (POC) diagnostic biosensors that operate reliably in physiologically relevant ionic strength solutions represents a significant challenge in bioanalytical engineering. Field-effect transistor-based biosensors (BioFETs), particularly those employing carbon nanotubes (CNTs), offer exceptional electrical sensitivity and fabrication versatility [2]. However, two persistent issues have hindered their practical implementation: signal drift over time and the charge screening effect at high ionic strengths, which severely limits detection sensitivity [2]. This case study examines the D4-TFT biosensor, an innovative platform that integrates a poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA) polymer brush interface to overcome these limitations. The D4-TFT achieves attomolar-level detection in 1X phosphate-buffered saline (PBS)—a solution with ionic strength equivalent to physiological fluids—making it a groundbreaking tool for researchers, scientists, and drug development professionals working on ultrasensitive diagnostic platforms [2].

Technical Challenges in BioFET Development

Signal Drift and Debye Length Screening

BioFETs operating in solutions at biologically relevant ionic strengths face fundamental physical constraints that compromise their reliability and sensitivity:

Signal Drift: Electrolytic ions from the solution slowly diffuse into the sensing region over time, altering gate capacitance, drain current, and threshold voltage [2]. This temporal instability can generate data that falsely suggests successful biomarker detection, particularly when the drift direction aligns with the expected device response [2].

Debye Length Screening: In biological solutions like 1X PBS, an electrical double layer forms at a specific distance (typically angstroms to a few nanometers) above the sensor surface, creating a screening barrier that prevents charged molecules beyond this length from influencing the FET channel [2]. Since antibodies are approximately 10 nm in size, any antibody-analyte interaction occurs beyond the Debye length and would be undetectable with a conventional BioFET [2].

Conventional Workarounds and Their Limitations

Traditional approaches to these challenges have proven inadequate for POC applications:

- Buffer Dilution: Testing in diluted solutions extends the Debye length but compromises biological relevance and clinical applicability [2].

- Bulky Reference Electrodes: Using Ag/AgCl electrodes enhances stability but limits portability and POC compatibility [2].

- Short Bioreceptors: Employing aptamers or antibody fragments addresses size constraints but may compromise binding affinity and specificity [2].

The D4-TFT Biosensor Platform

The D4-TFT architecture represents a significant advancement building upon three key technological developments: the fluorescence D4 immunoassay platform, POEGMA growth on high-κ dielectrics, and encapsulated solution-gated devices for leakage current mitigation [2]. The device operates through four sequential steps that form the basis of its name:

- Dispense: A sample containing the target biomarker is dispensed onto the sensor.

- Dissolve: A readily-dissolvable trehalose layer containing detection antibodies dissolves upon contact with the sample.

- Diffuse: Detection antibodies and target analytes diffuse toward the sensor surface.

- Detect: Target capture between surface-immobilized antibodies and detection antibodies generates an electrical signal measured by the CNT thin-film transistor [2].

The biosensor utilizes a sandwich immunoassay format where the target biomarker is captured between antibodies immobilized in the POEGMA brush layer above the CNT channel and enzyme-conjugated detection antibodies [2]. A control device with no antibodies printed over the CNT channel confirms specific detection via current shifts caused exclusively by antibody sandwich formation [2].

POEGMA Polymer Brush Interface: Mechanism of Action

The POEGMA polymer brush serves two critical functions in the D4-TFT platform:

Debye Length Extension: The POEGMA layer effectively increases the sensing distance in solution (Debye length) by establishing a Donnan equilibrium potential, overcoming charge screening limitations in high ionic strength environments [2]. This enables the detection of antibody-analyte interactions that would normally occur beyond the detectable range in conventional BioFETs.

Anti-Fouling Properties: The non-fouling characteristics of POEGMA prevent non-specific binding of biomolecules to the sensor surface, maintaining signal integrity and reducing background noise [2]. Recent investigations using total internal reflection microscopy (TIRM) have provided valuable insights into the swelling behavior and conformational properties of POEGMA brushes in aqueous solutions, enhancing our understanding of their performance in biosensing applications [7].

Key Experimental Protocols

Device Fabrication and Functionalization

Objective: Create a stable CNT-based BioFET with integrated POEGMA brush interface for attomolar detection in PBS.

Materials:

- Semiconducting carbon nanotubes (CNTs)

- Poly(oligo(ethylene glycol) methyl ether methacrylate) (POEGMA)

- Capture antibodies specific to target biomarker

- Palladium (Pd) pseudo-reference electrode

- Passivation materials for device stability

- Phosphate-buffered saline (PBS), pH 7.4

Procedure:

- CNT Thin-Film Deposition: Deposit semiconducting CNTs to form the channel of the field-effect transistor using solution-phase processing techniques [2].

- POEGMA Brush Immobilization: Grow POEGMA polymer brushes on the sensing surface using surface-initiated polymerization to establish a non-fouling interface with extended Debye length capabilities [2].

- Antibody Printing: Precisely print capture antibodies into the POEGMA matrix above the CNT channel using inkjet printing technology [2].

- Control Device Preparation: Fabricate control devices with identical configuration but without antibodies printed over the CNT channel to distinguish specific binding from non-specific effects [2].

- Passivation and Encapsulation: Apply appropriate passivation layers alongside the polymer brush coating to maximize sensitivity and operational stability [2].

- Pd Pseudo-Reference Electrode Integration: Implement a palladium pseudo-reference electrode to eliminate the need for bulky Ag/AgCl electrodes, enabling a compact POC form factor [2].

Biosensing Measurement Methodology

Objective: Achieve drift-compensated attomolar detection of target biomarkers in undiluted PBS.

Materials:

- D4-TFT biosensor platform

- Target biomarker standards in 1X PBS

- Detection antibody conjugates in dissolvable trehalose layer

- Automated potentiostat system with DC sweep capability

- Data acquisition and analysis software

Procedure:

- Sample Dispensing: Apply the sample containing the target biomarker to the D4-TFT biosensor [2].

- Trehalose Dissolution: Allow the readily-dissolvable excipient layer (trehalose) containing detection antibodies to dissolve upon contact with the sample solution [2].

- Analyte Diffusion: Incubate to permit target biomarkers and detection antibodies to diffuse toward the sensor surface [2].

- Sandwich Complex Formation: Facilitate the formation of antibody-target-detection antibody sandwich complexes within the POEGMA brush interface [2].

- Electrical Measurement:

- Control Measurement: Simultaneously test control devices without antibodies to confirm specific detection and account for non-specific binding or drift artifacts [2].

- Data Analysis: Quantify target concentration based on current shift relative to control devices, using appropriate calibration curves [2].

Table 1: Key Performance Metrics of the D4-TFT Biosensor

| Parameter | Performance Value | Significance |

|---|---|---|

| Detection Limit | Attomolar (aM) level | Enables detection of ultralow biomarker concentrations |

| Operating Solution | 1X PBS (physiological ionic strength) | Maintains biological relevance without buffer dilution |

| Signal Drift Management | Effectively mitigated | Ensures measurement reliability and accuracy |

| Form Factor | Point-of-care compatible | Enables bedside or resource-limited testing |

Research Reagent Solutions

Table 2: Essential Materials for D4-TFT Biosensor Implementation

| Research Reagent | Function in Experimental Protocol |

|---|---|

| Semiconducting Carbon Nanotubes (CNTs) | Forms the high-sensitivity channel of the thin-film transistor [2] |

| POEGMA Polymer Brushes | Extends Debye length and provides anti-fouling interface [2] [7] |

| Specific Capture Antibodies | Recognizes and binds target biomarkers with high specificity [2] |

| Pd Pseudo-Reference Electrode | Provides stable reference potential without bulky Ag/AgCl systems [2] |

| Trehalose Excipient Layer | Dissolvable matrix for storage and delivery of detection antibodies [2] |

| Passivation Materials | Enhances device stability and minimizes signal drift [2] |

Results and Discussion

Performance Validation and Technical Advantages

The D4-TFT biosensor platform demonstrates exceptional performance characteristics that address the fundamental limitations of conventional BioFETs:

Ultrahigh Sensitivity in Physiological Buffers: The platform successfully detects sub-femtomolar biomarker concentrations directly in 1X PBS, overcoming the Debye screening limitation that has plagued traditional BioFETs [2]. This represents a significant advancement over previous technologies that required buffer dilution or replacement to achieve comparable sensitivity.

Effective Signal Drift Mitigation: Through the combination of optimized passivation, stable electrical configurations, and rigorous DC sweep methodologies, the D4-TFT platform achieves stable, repeatable measurements that distinguish true biomarker binding from temporal drift artifacts [2]. The implementation of control devices with no antibodies provides critical validation of specific detection events.

Point-of-Care Compatibility: The integration of a Pd pseudo-reference electrode eliminates the need for bulky Ag/AgCl systems, while the automated testing platform enables operation in non-laboratory settings [2]. This combination of features represents significant progress toward truly deployable POC diagnostic platforms.

Technological Implications and Future Directions

The successful integration of POEGMA polymer brushes within the D4-TFT architecture provides a compelling case study in interfacial engineering for biosensing applications. The demonstrated ability to control the molecular environment at the bioelectronic interface opens new possibilities for detecting low-abundance biomarkers in complex biological fluids. Future developments may focus on multiplexed detection capabilities, further miniaturization for wearable applications, and expansion to additional biomarker classes including nucleic acids and viral particles.

Visualized Workflows

D4-TFT Biosensing Workflow

POEGMA Mechanism of Action

Drift Mitigation Strategy